2025

Toward in situ monitoring of 3D surface topography in laser powder bed fusion additive manufacturing via polarized imaging

Lucà, F., Chiariotti, P., Bugatti, M., Grasso, M., Rigone, S., Zappa, E., & Colosimo, B. M.

Progress in Additive Manufacturing, 1-17.

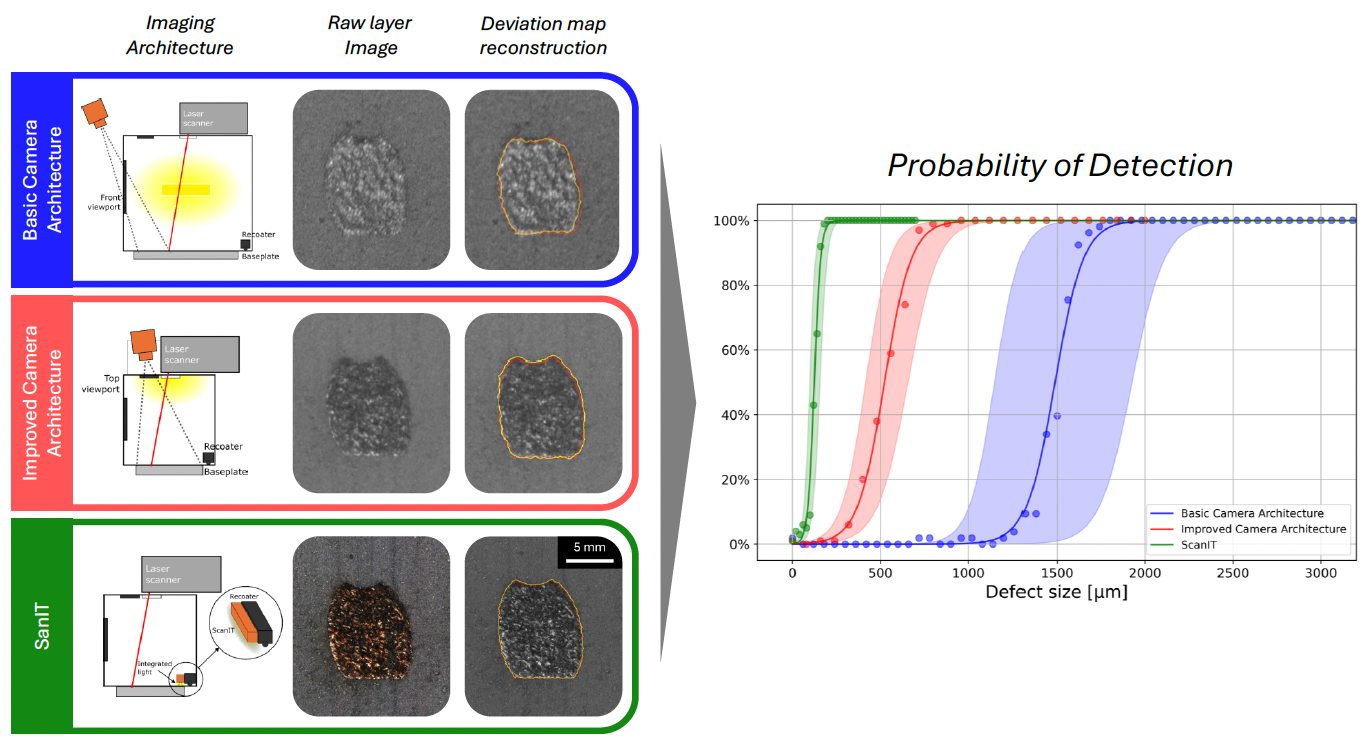

In-situ monitoring of geometrical defects in laser powder bed fusion: probability of detection across defect sizes and sensor architectures

Bugatti, M., Grasso, M., & Colosimo, B. M. Progress in Additive Manufacturing, 1-12.

2024

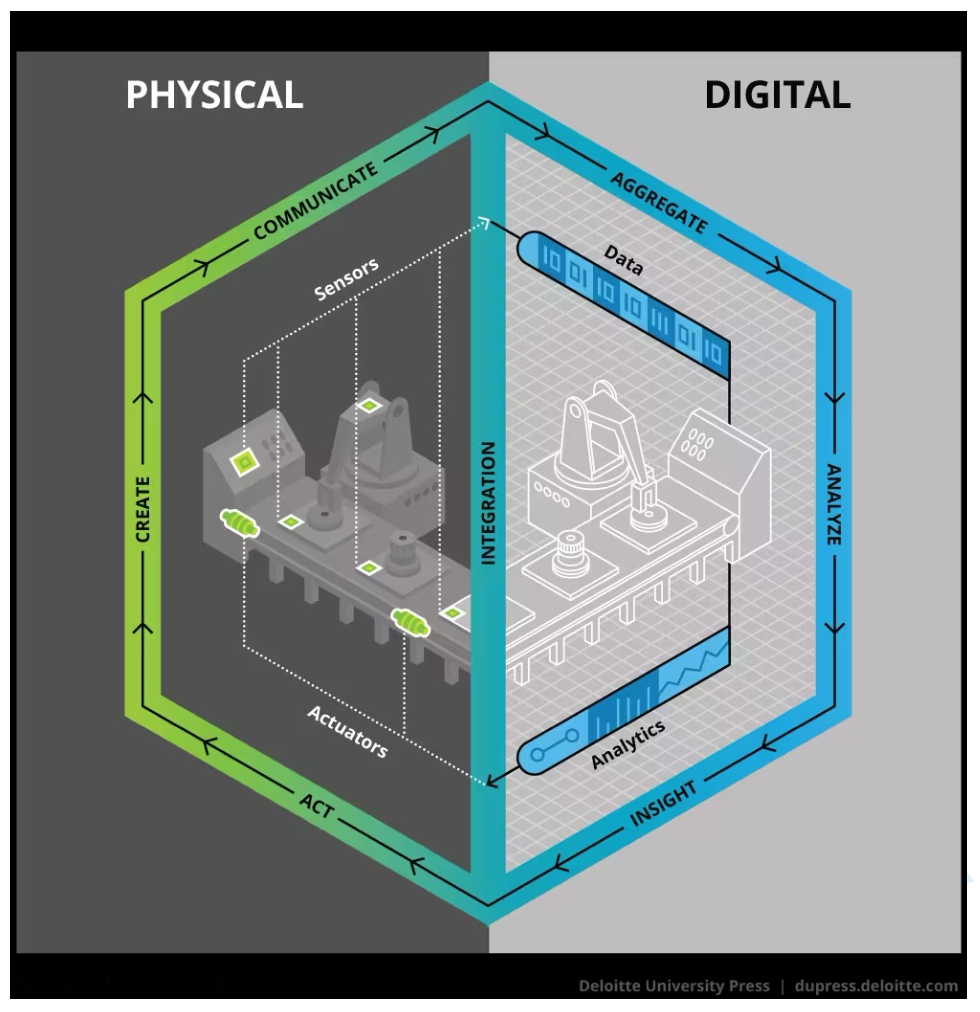

Process Monitoring from Industry 2.0 to Industry 4.0: Insights into Research and Practice

Colosimo, B. M., Jones-Farmer, L. A., Megahed, F. M., Paynabar, K., Ranjan, C., & Woodall, W. H.

Technometrics (2024): 1-24.

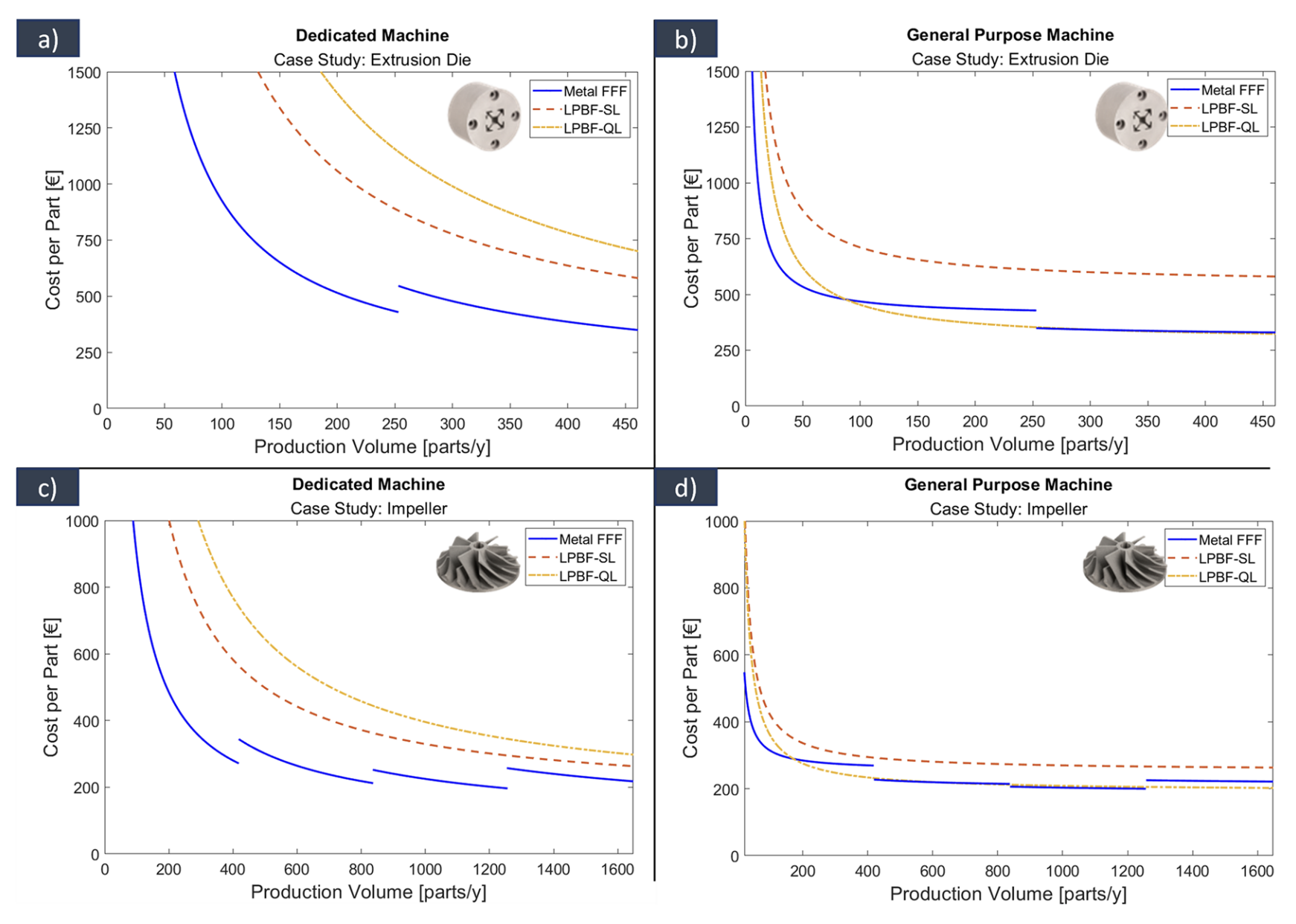

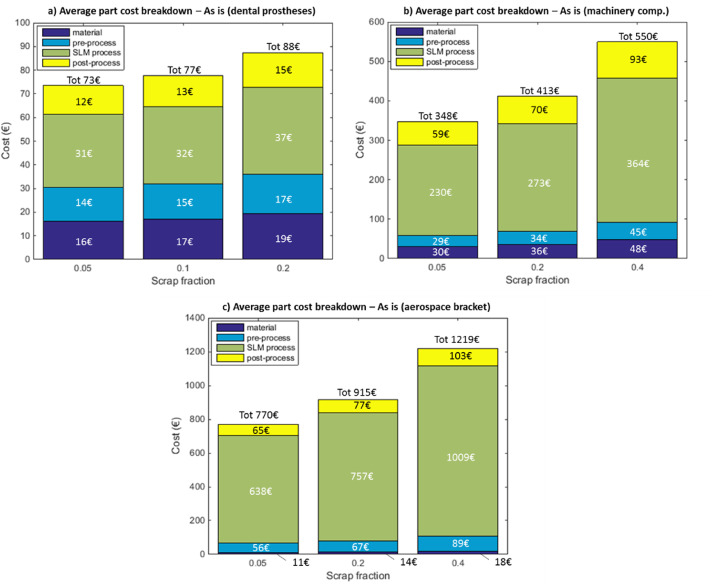

A techno-economic approach for decision-making in metal additive manufacturing: metal extrusion versus single and multiple laser powder bed fusion.

Parenti, P., Puccio, D., Semeraro, Q., & Colosimo, B. M.

Progress in Additive Manufacturing, 9(2), 185-210

https://link.springer.com/article/10.1007/s40964-023-00442-7

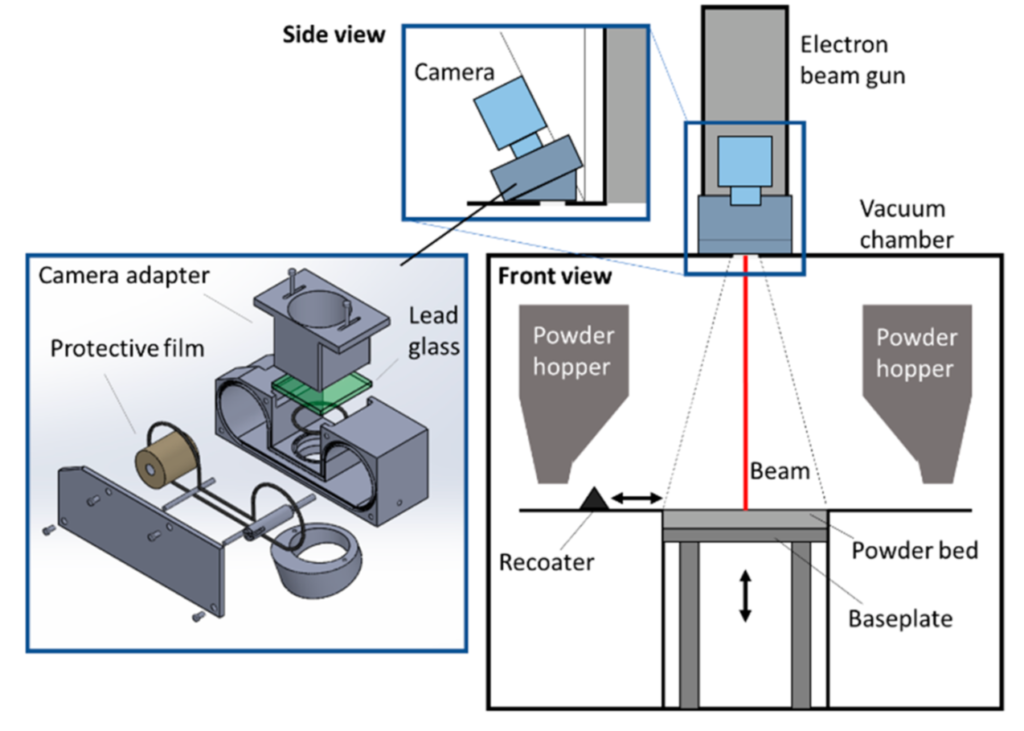

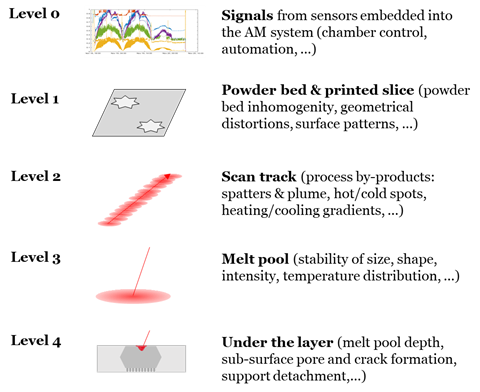

A review of the current state-of-the-art on in situ monitoring in electron beam powder bed fusion

Grasso, M., & Colosimo, B. M.

Progress in Additive Manufacturing (2024): 1-18.

https://link.springer.com/article/10.1007/s40964-024-00576-2

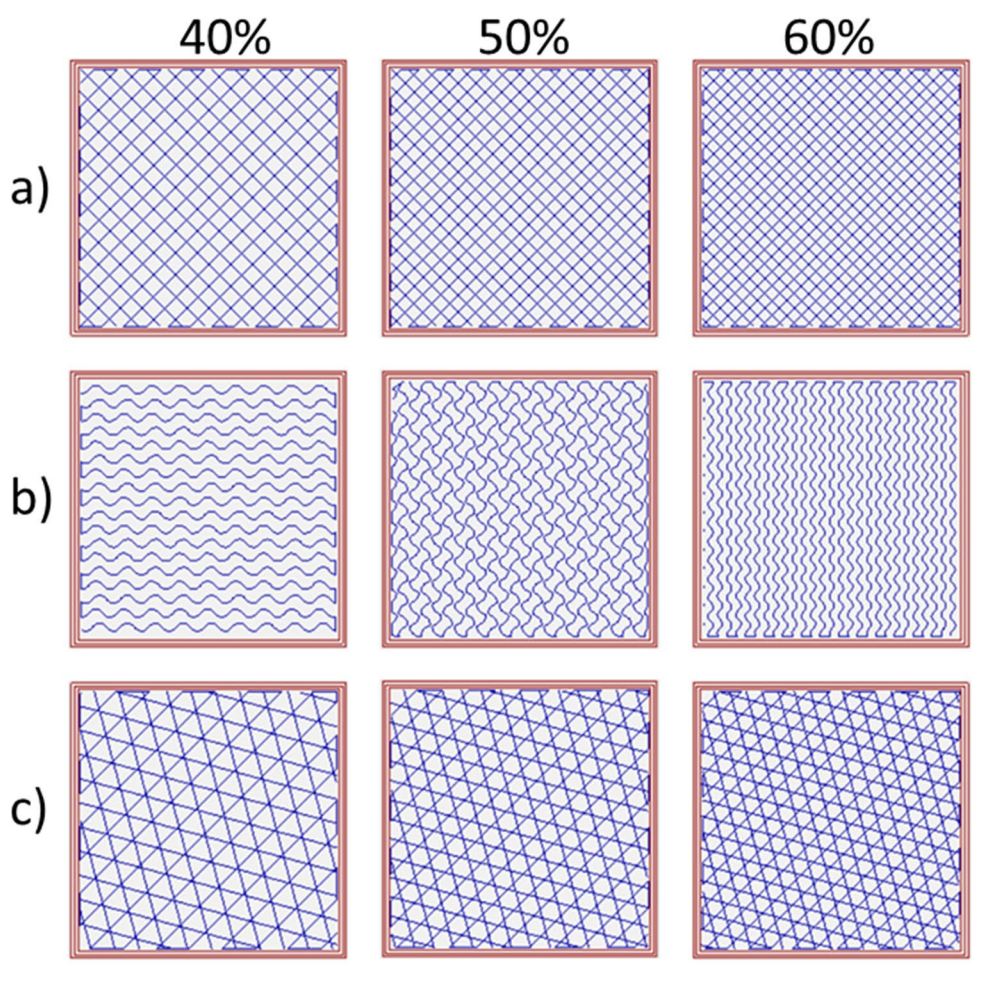

3D-printed boluses for radiotherapy: influence of geometrical and printing parameters on dosimetric characterization and air gap evaluation

Gugliandolo, S. G., Pillai, S. P., Rajendran, S., Vincini, M. G., Pepa, M., Pansini, F., … & Colosimo, B. M.

Radiological Physics and Technology (2024): 1-13

https://link.springer.com/article/10.1007/s12194-024-00782-1

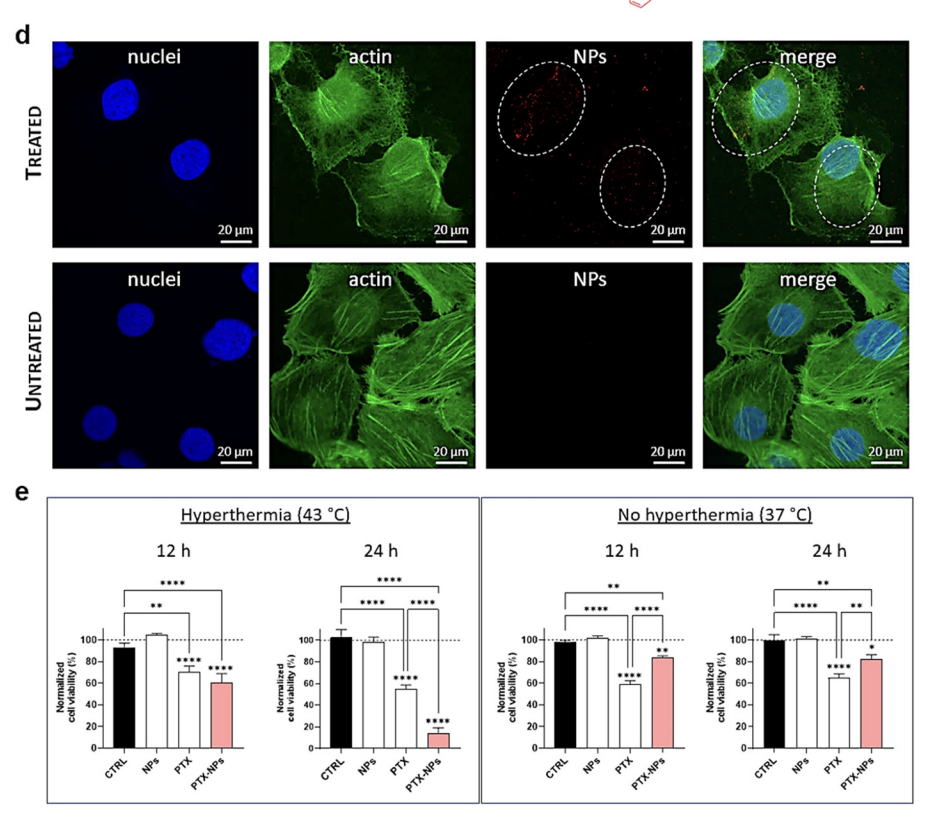

Zwitterionic nanoparticles for thermally activated drug delivery in hyperthermia cancer treatment

Colli, C., Masi, I., Jacchetti, E., Santoni, S., Sponchioni, M., Colosimo, B. M., … & Moscatelli, D.

Nanoscale (2024)

https://pubs.rsc.org/en/content/articlelanding/2024/nr/d4nr00723a

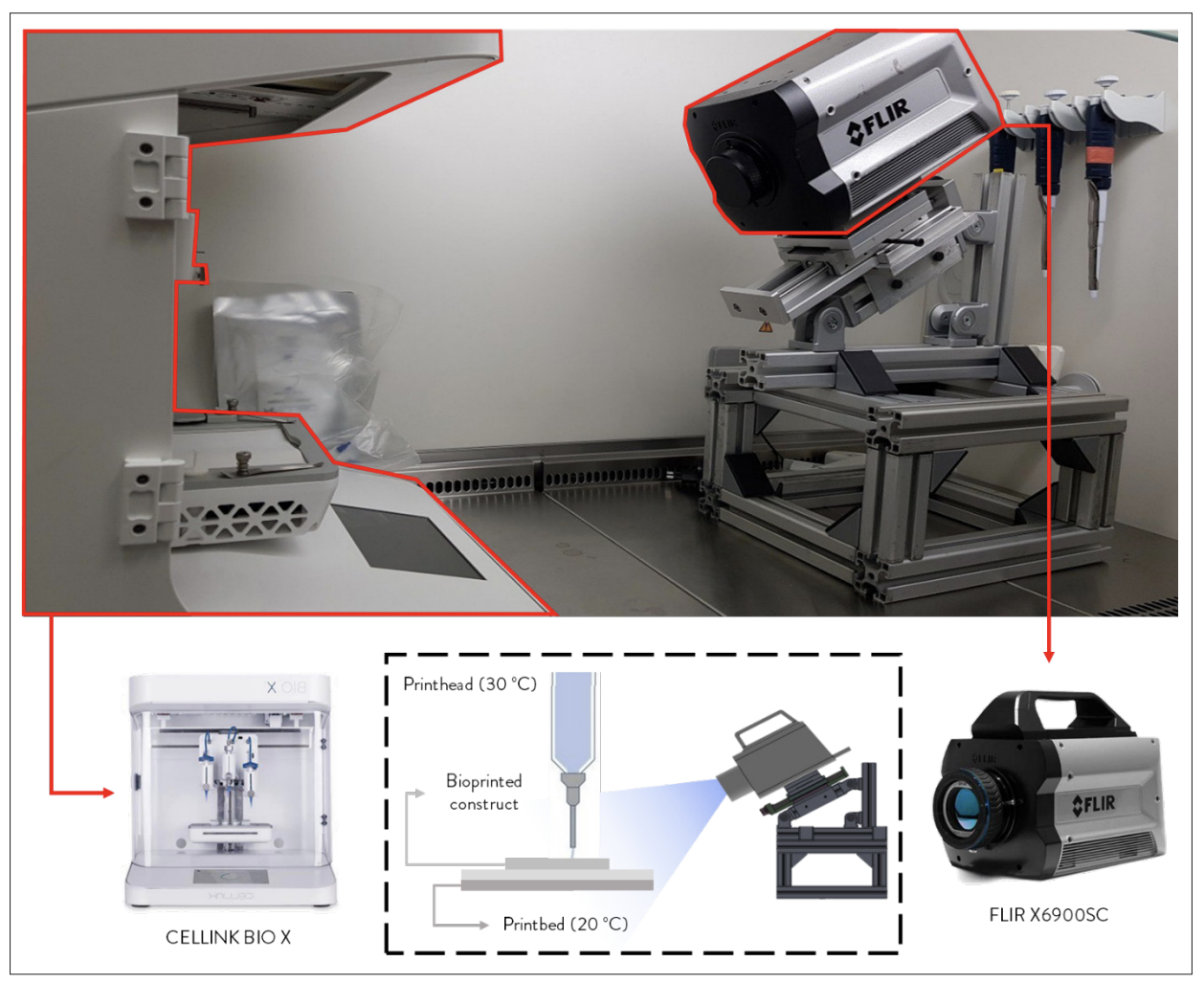

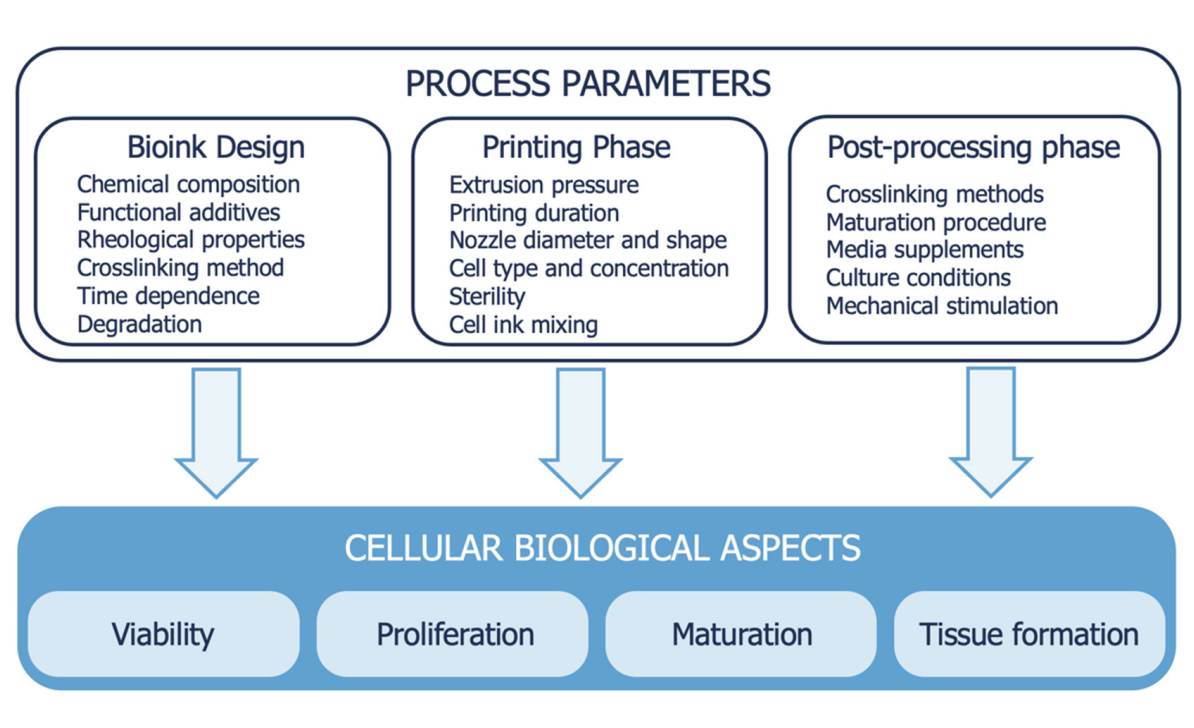

A new solution for in situ monitoring of shape fidelity in extrusion-based bioprinting via thermal imaging

Gugliandolo, S. G., Prioglio, E., Moscatelli, D., & Colosimo, B.M.

International Journal of Bioprinting NA (2024): 1-14

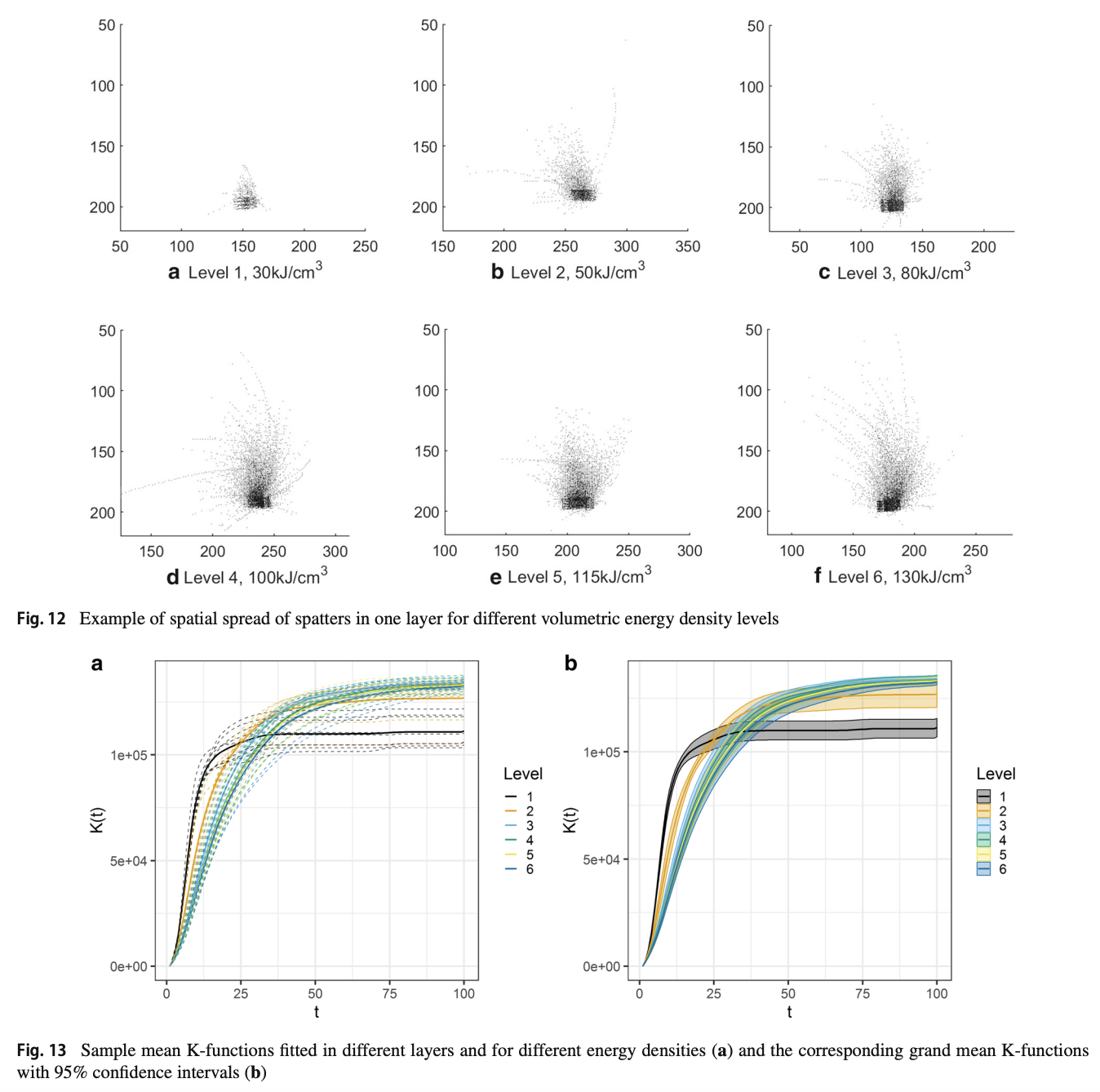

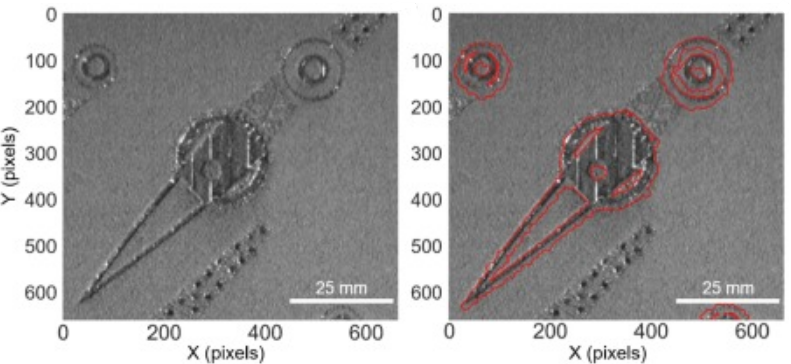

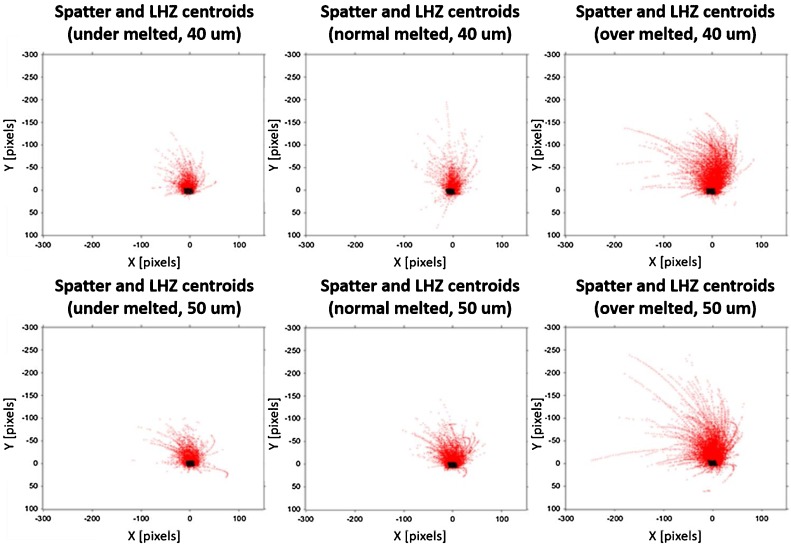

Modeling spatial point processes in video-imaging via Ripley’s K-function: an application to spatter analysis in additive manufacturing

Colosimo, B. M., Pagani, L., & Grasso, M.

Journal of Intelligent Manufacturing (2024) 35(1), 429-447

https://link.springer.com/article/10.1007/s10845-022-02055-3

2023

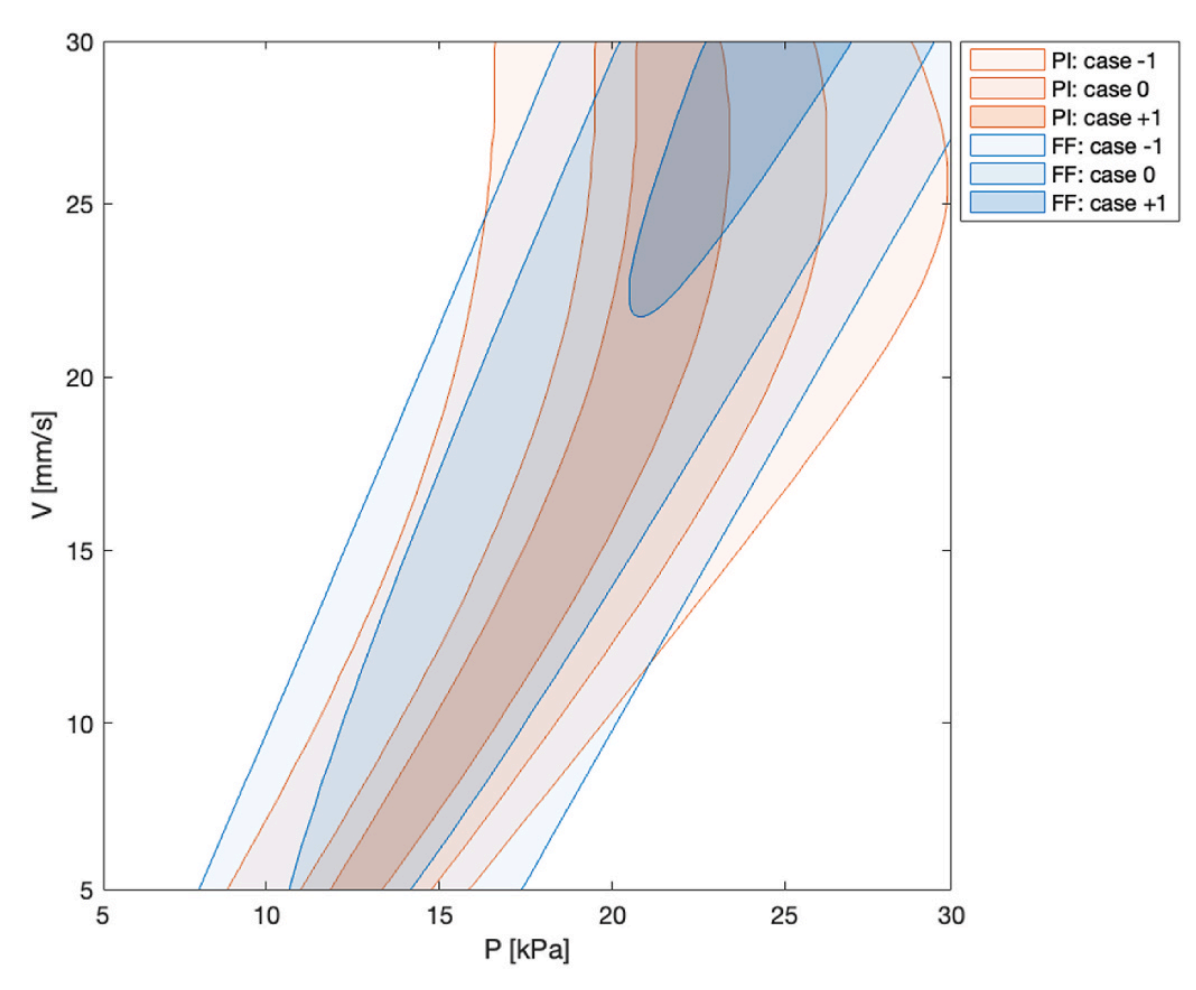

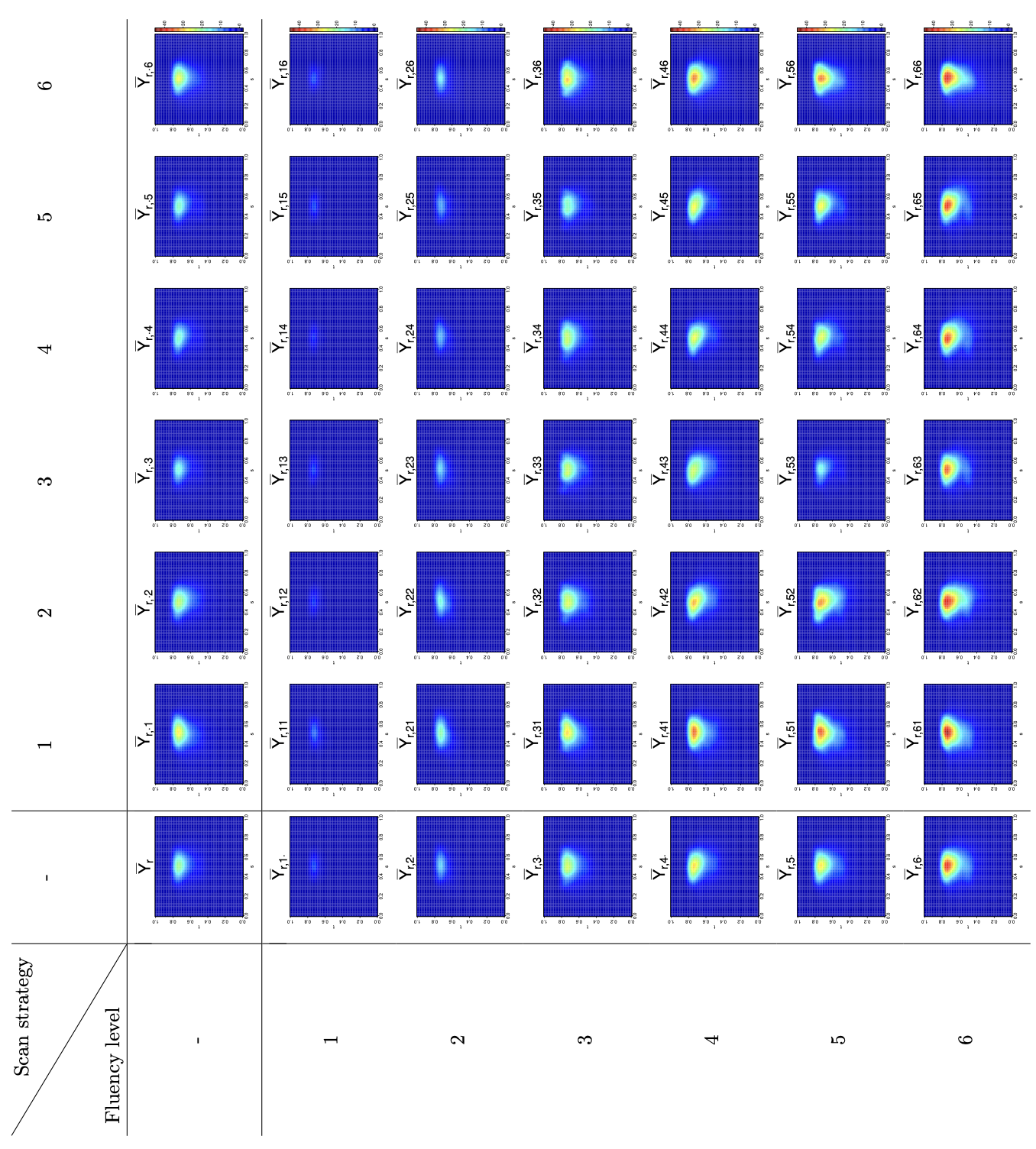

In-situ Printability Maps (IPM): A new approach for in-situ printability assessment with application to extrusion-based bioprinting

Zanderigo, G., Bracco, F., Semeraro, Q., & Colosimo, B. M.

Bioprinting (2023), 36, e00320

Additive manufacturing in the new space economy: Current achievements and future perspectives

Ghidini, T., Grasso, M., Gumpinger, J., Makaya, A., & Colosimo, B. M.

Progress in Aerospace Sciences (2023): 100959

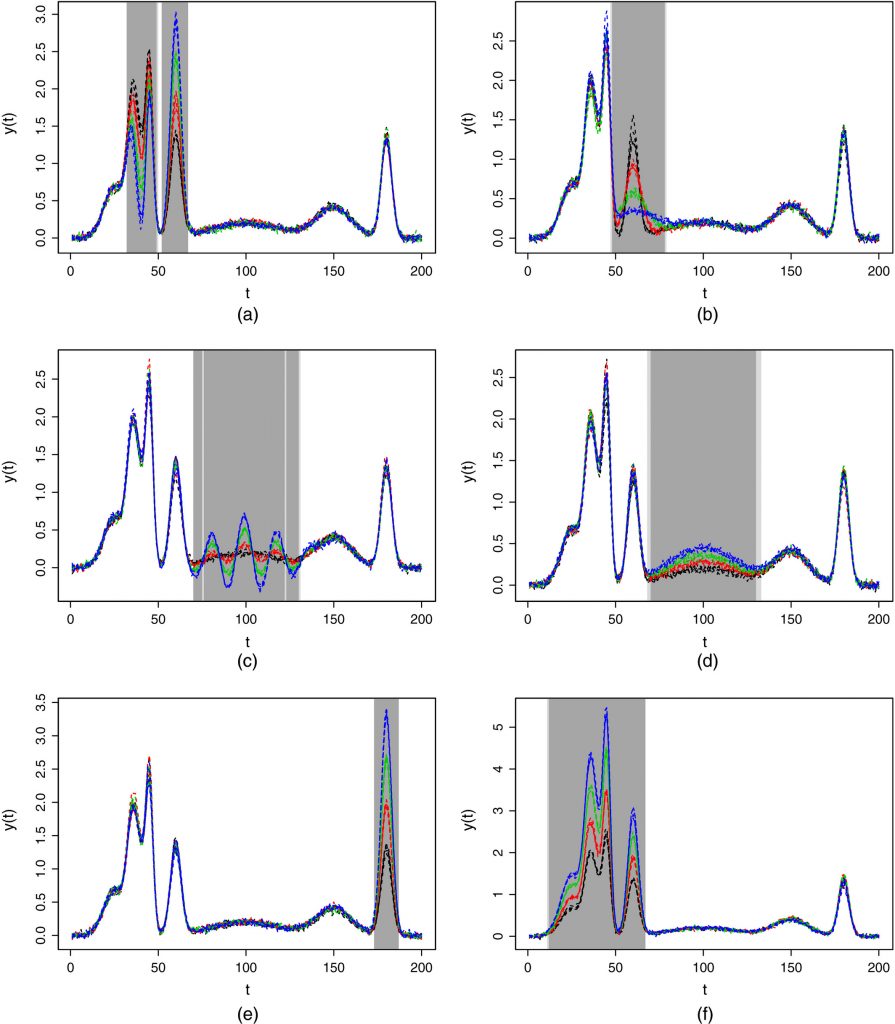

Robust functional ANOVA with application to additive manufacturing

Centofanti, F., Colosimo, B. M., Grasso, M. L., Menafoglio, A., Palumbo, B., & Vantini, S.

Journal of the Royal Statistical Society Series C: Applied Statistics, 72(5), 1210-1234

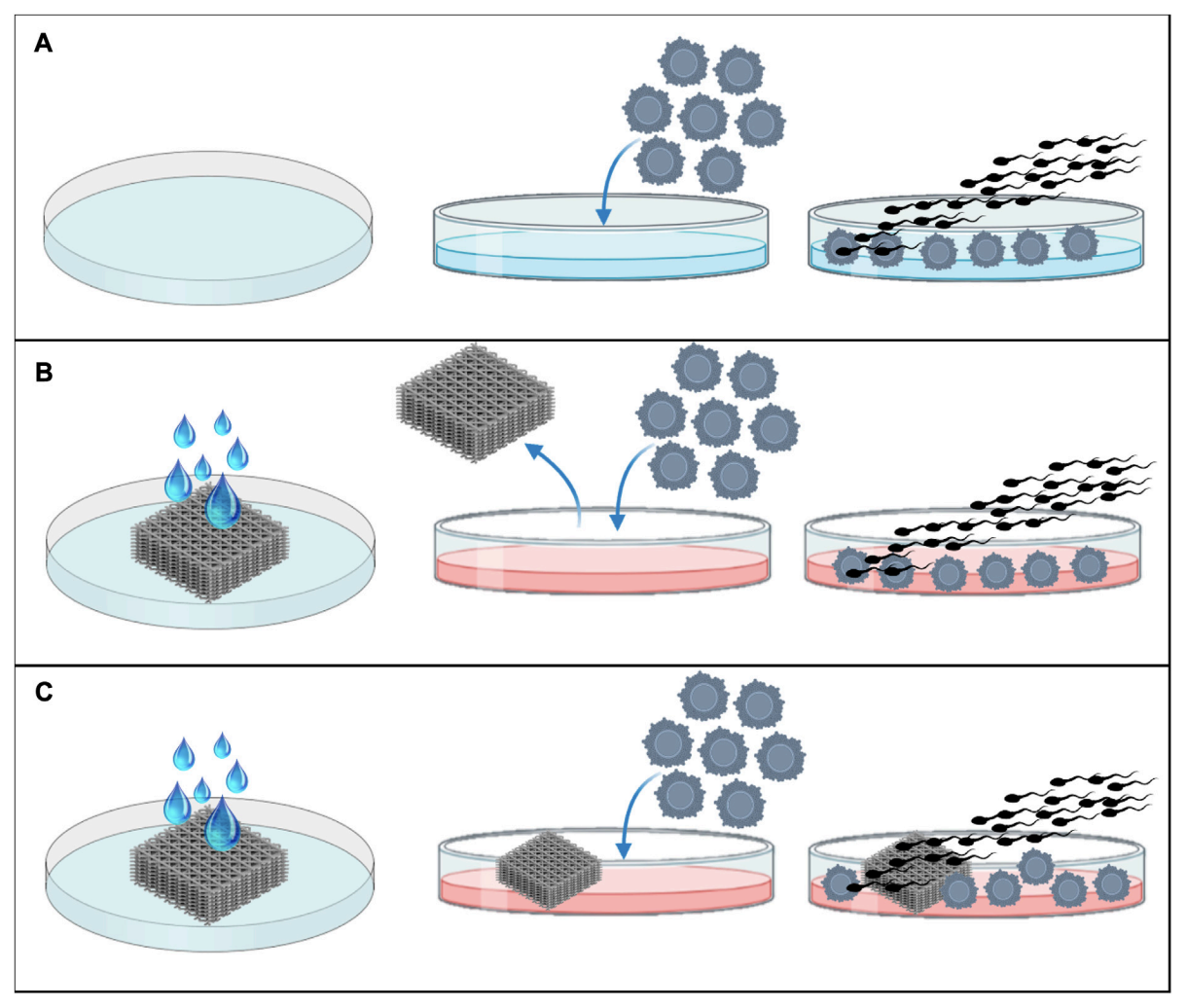

Advancing bovine in vitro fertilization through 3D printing: the effect of the 3D printed materials

Belda-Perez, R., Heras, S., Cimini, C., Romero-Aguirregomezcorta, J., Valbonetti, L., Colosimo, A., … & Coy, P.

Frontiers in Bioengineering and Biotechnology, 11, 1260886

In-situ monitoring of image texturing via random forests and clustering with applications to additive manufacturing

Caltanissetta, F., Bertoli, L., & Colosimo, B. M.

IISE Transactions (2023): 1-15

https://www.tandfonline.com/doi/abs/10.1080/24725854.2023.2257255

The data that support the findings of this study are openly available in figshare at https://doi.org/10.6084/m9.figshare.24042891.v1

3D bioprinting in microgravity: opportunities, challenges, and possible applications in space

Van Ombergen, A., Chalupa‐Gantner, F., Chansoria, P., Colosimo, B. M., Costantini, M., Domingos, M., … & Gelinsky, M.

Advanced healthcare materials, 12(23), 2300443

https://onlinelibrary.wiley.com/doi/full/10.1002/adhm.202300443

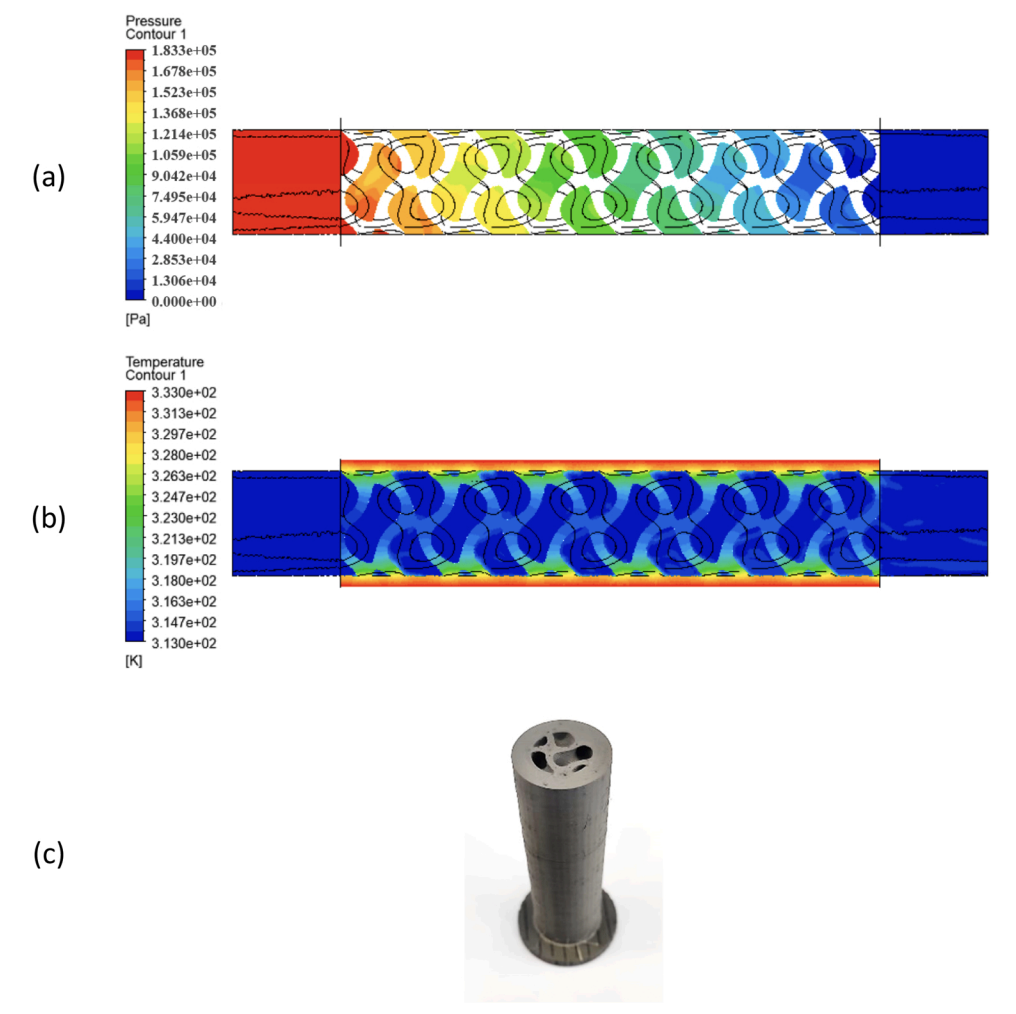

Cooled pads with bioinspired gyroid lattice for tilting pad journal bearings: Experimental validation of numerical model for heat transfer

Dassi, L., Chatterton, S., Parenti, P., Vania, A., Colosimo, B. M., Pennacchi, P.

Tribology International 184 (2023): 108448

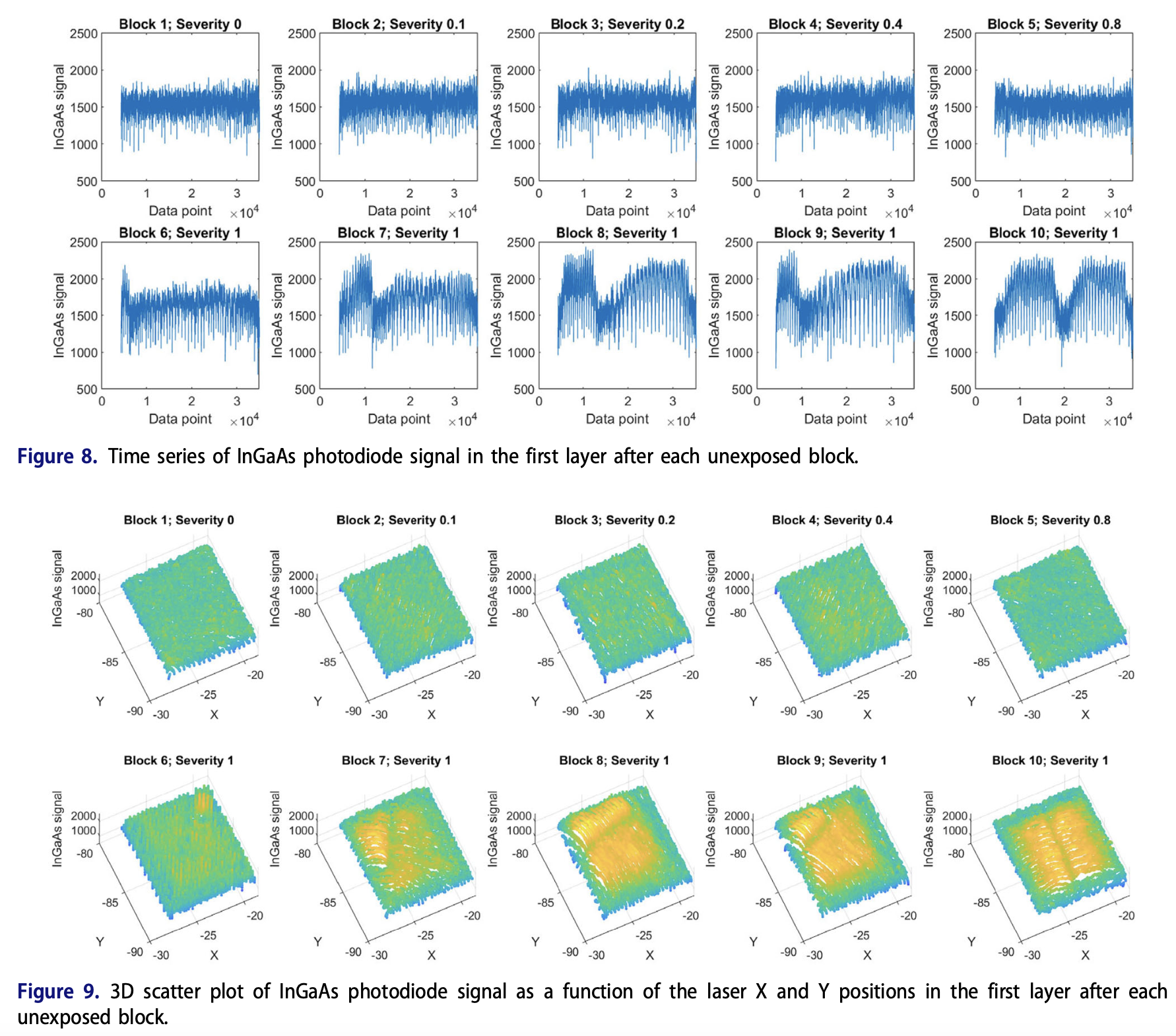

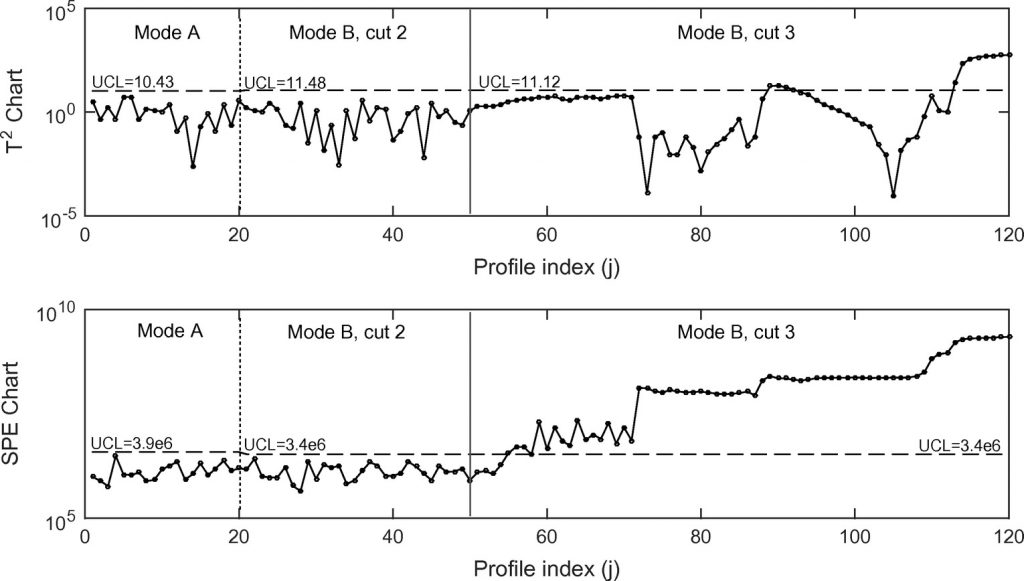

Open data for open science in Industry 4.0: In-situ monitoring of quality in additive manufacturing

Gronle, M., Grasso, M., Granito, E., Schaal, F., & Colosimo, B. M.

Journal of Quality Technology, 55(2), 253-265

https://www.tandfonline.com/doi/full/10.1080/00224065.2022.2106910

All data are available at https://www.ic.polimi.it/open-data-challenge/

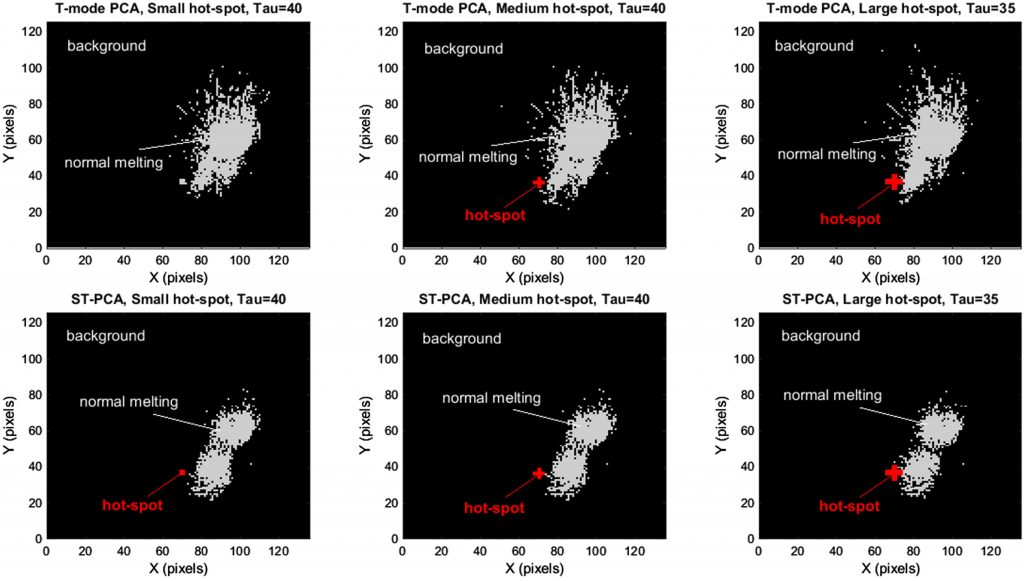

A tensor‐based hierarchical process monitoring approach for anomaly detection in additive manufacturing

Yang, W., Grasso, M., Colosimo, B. M., & Paynabar, K.

Quality and Reliability Engineering International, 39(2), 630-650.

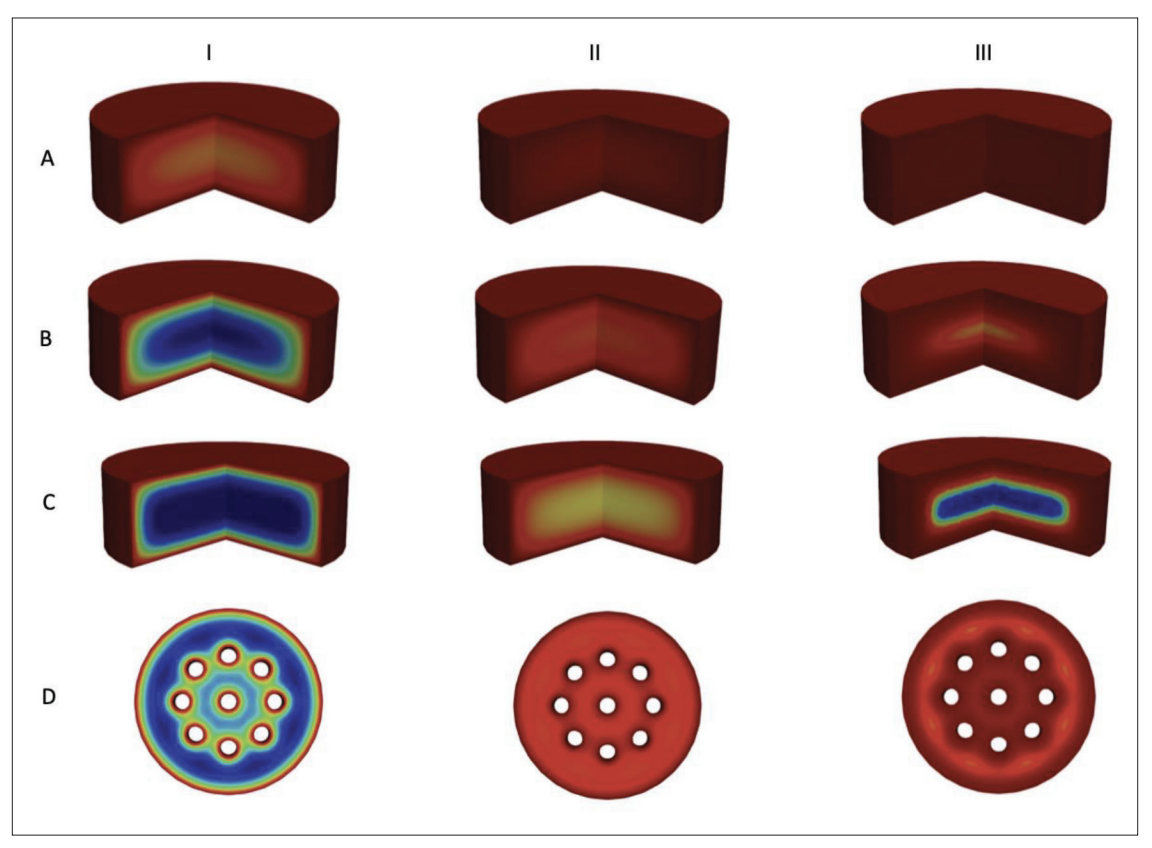

A computational model of cell viability and proliferation of extrusion-based 3D-bioprinted constructs during tissue maturation process

Gironi, P., Petraro, L., Santoni, S., Dedé, L., & Colosimo, B. M.

International Journal of Bioprinting 9.4 (2023).

2022

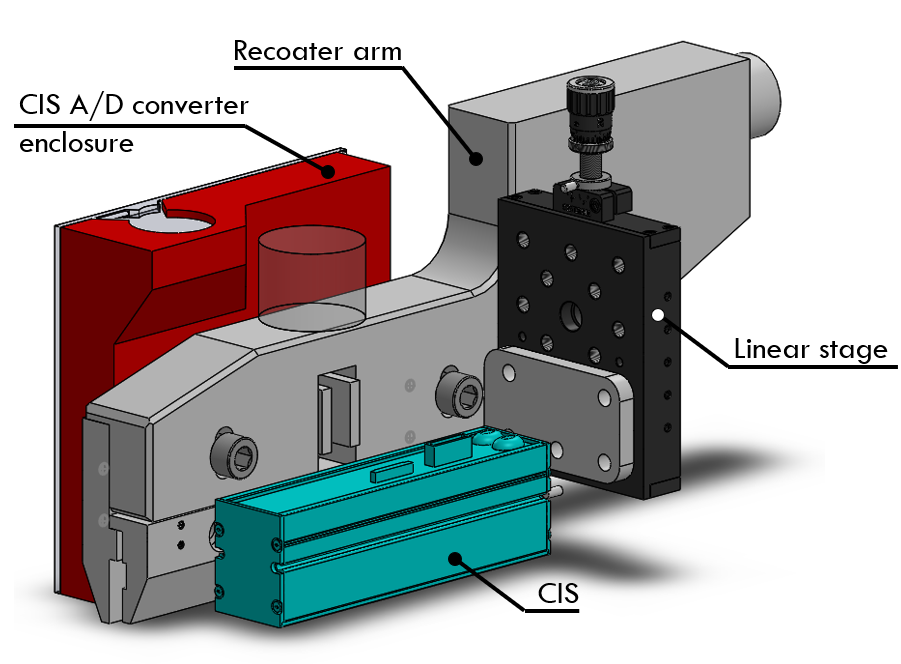

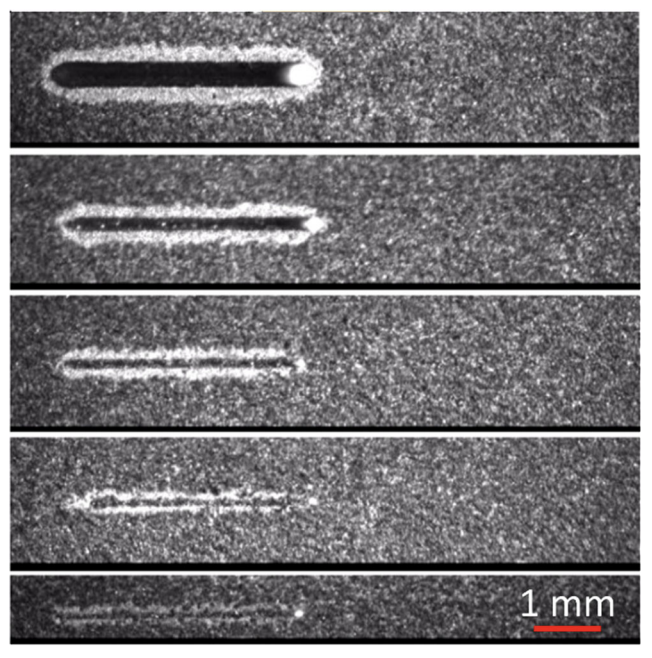

The intelligent recoater: A new solution for in-situ monitoring of geometric and surface defects in powder bed fusion

M. Bugatti and B. M. Colosimo

Additive Manufacturing Letters, Volume 3, 2022

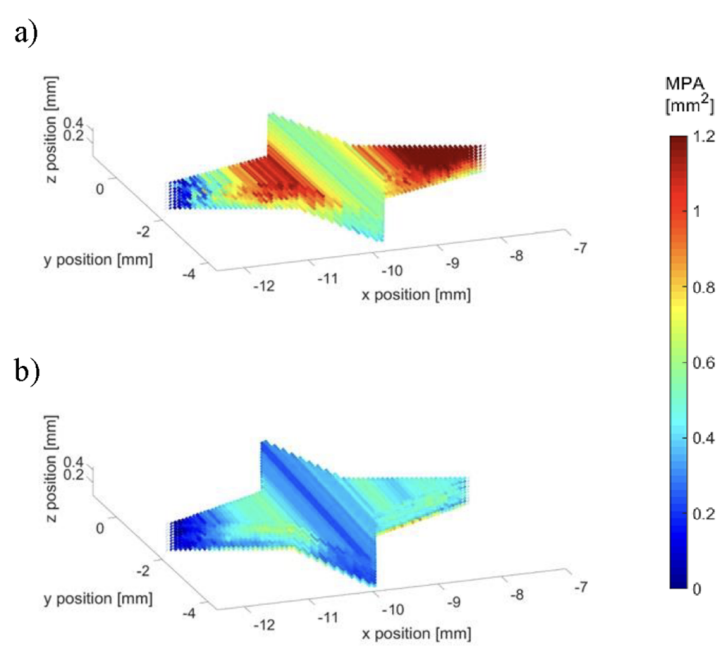

Effect of overhanging surfaces on the evolution of substrate topography and internal defects formation in laser powder bed fusion

M. Bugatti, Q. Semeraro, and B. M. Colosimo

Journal of Manufacturing Processes, vol. 77, no. November 2021, pp. 588–606

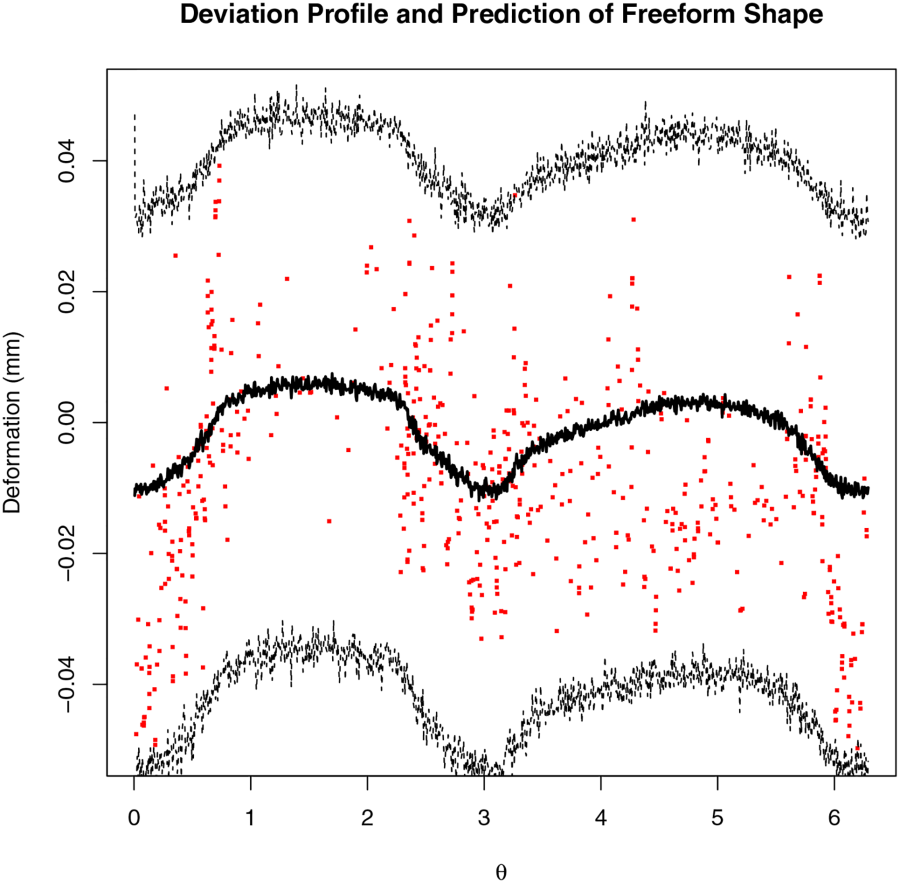

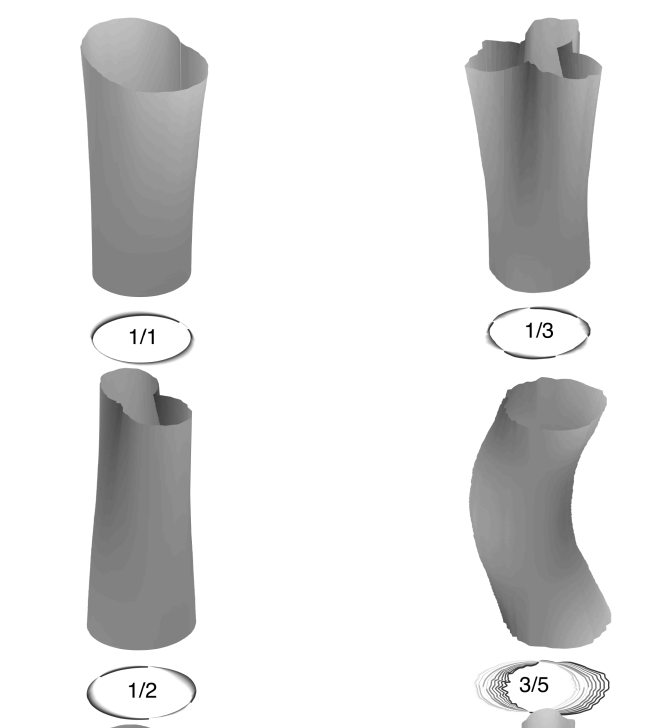

Statistical modeling and monitoring of geometrical deviations in complex shapes with application to additive manufacturing

Scimone, R., Taormina, T., Colosimo, B. M., Grasso, M., Menafoglio, A., & Secchi, P.

Technometrics, 64(4), 437-456.

https://www.tandfonline.com/doi/abs/10.1080/00401706.2021.1961870

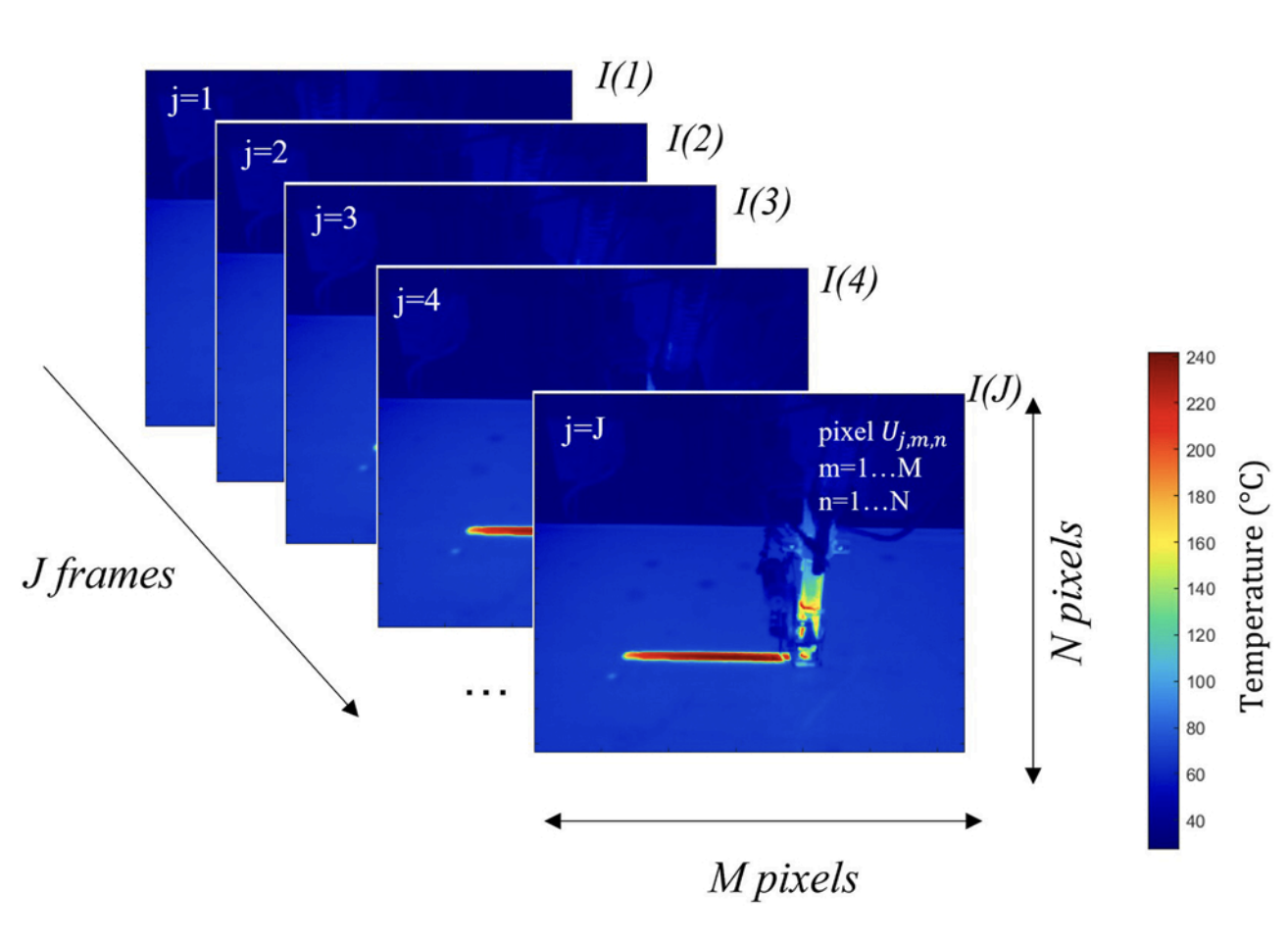

In-situ monitoring of material extrusion processes via thermal videoimaging with application to big area additive manufacturing (baam)

Caltanissetta, F., Dreifus, G., Hart, A. J., & Colosimo, B. M.

Additive Manufacturing 58 (2022): 102995

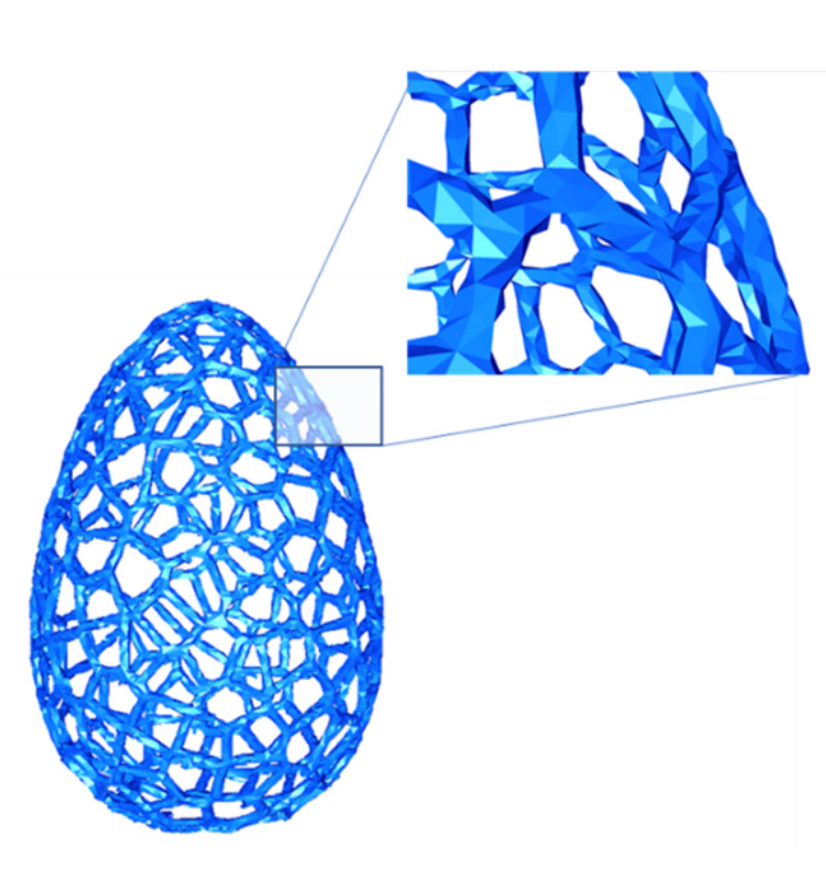

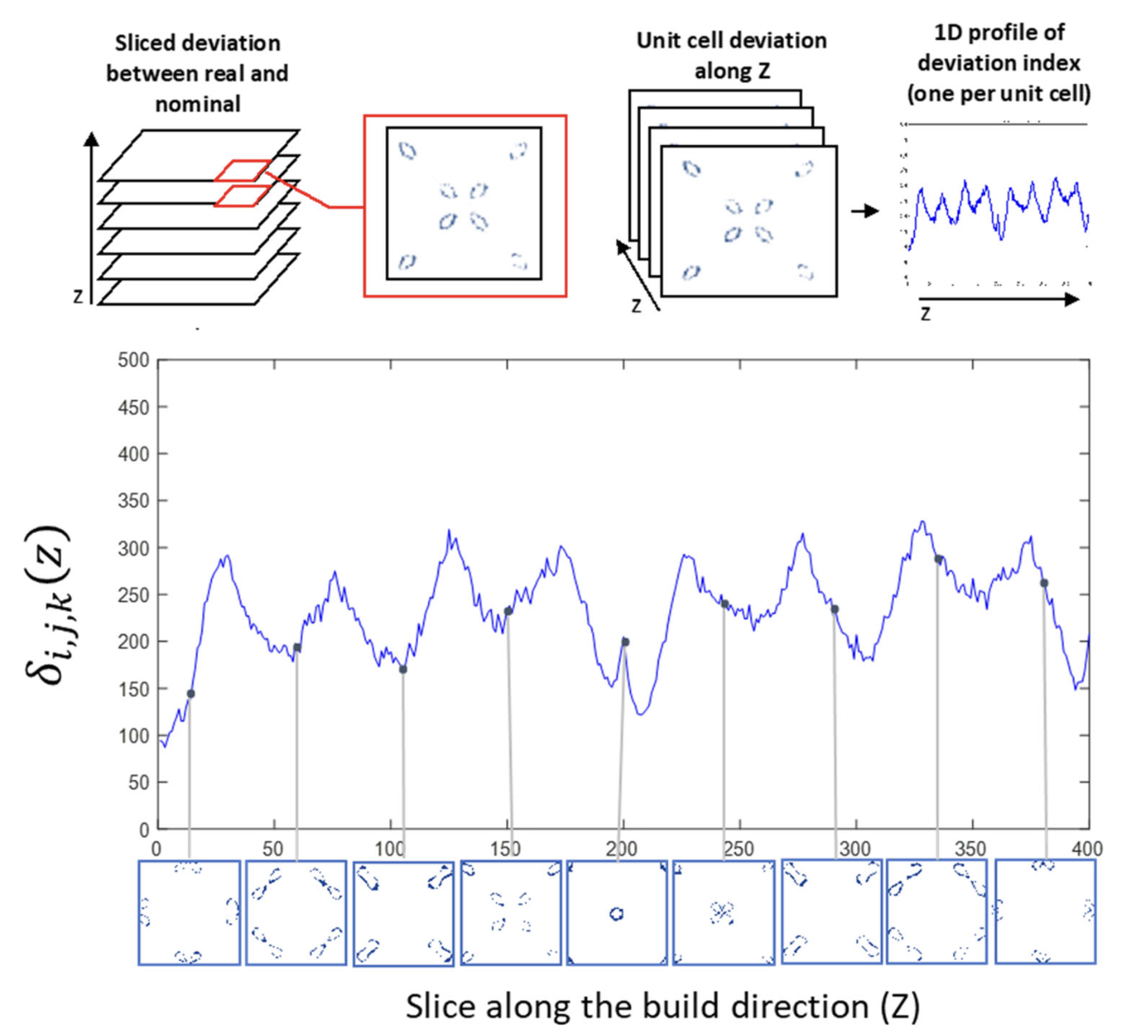

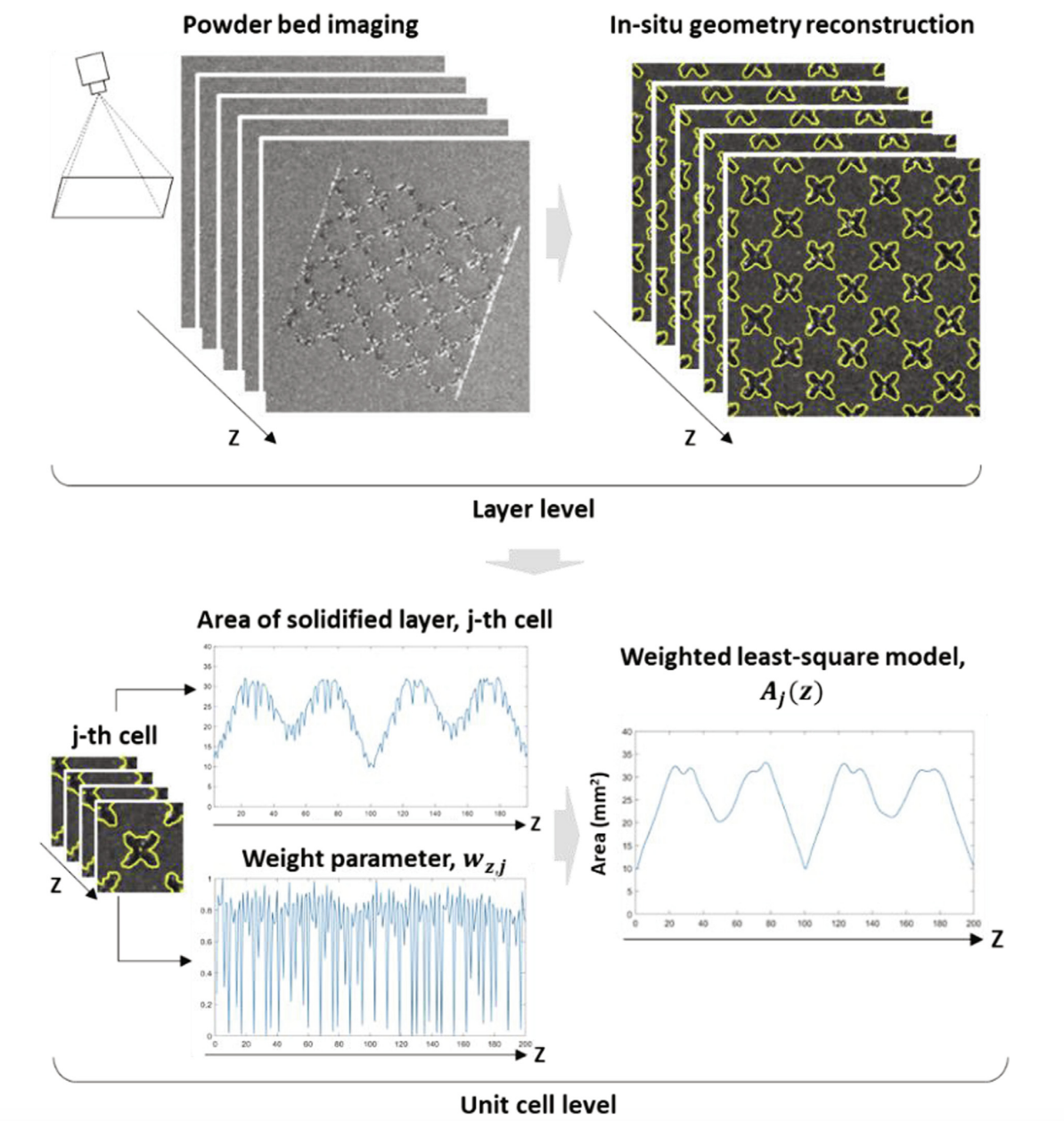

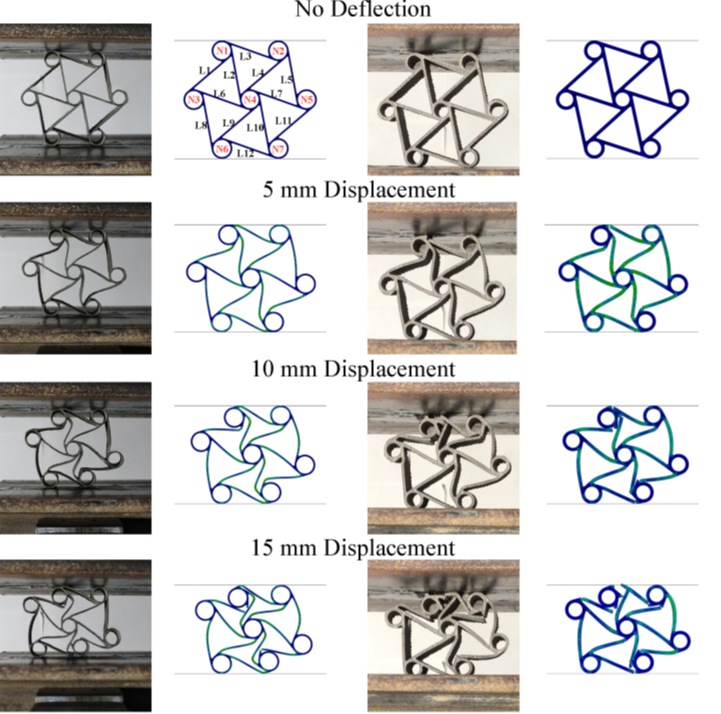

Complex geometries in additive manufacturing: A new solution for lattice structure modeling and monitoring

Colosimo, B. M., Grasso, M., Garghetti, F., & Rossi, B.

Journal of Quality Technology, 54(4), 392-414

https://www.tandfonline.com/doi/full/10.1080/00224065.2021.1926377

Biotechnological and technical challenges related to cultured meat production

Lanzoni, D., Bracco, F., Cheli, F., Colosimo, B. M., Moscatelli, D., Baldi, A., … & Giromini, C.

Applied Sciences, 12(13), 6771

A novel method for in-process inspection of lattice structures via in-situ layerwise imaging

Colosimo, B. M., Garghetti, F., Pagani, L., & Grasso, M

Manufacturing Letters 32 (2022): 67-72

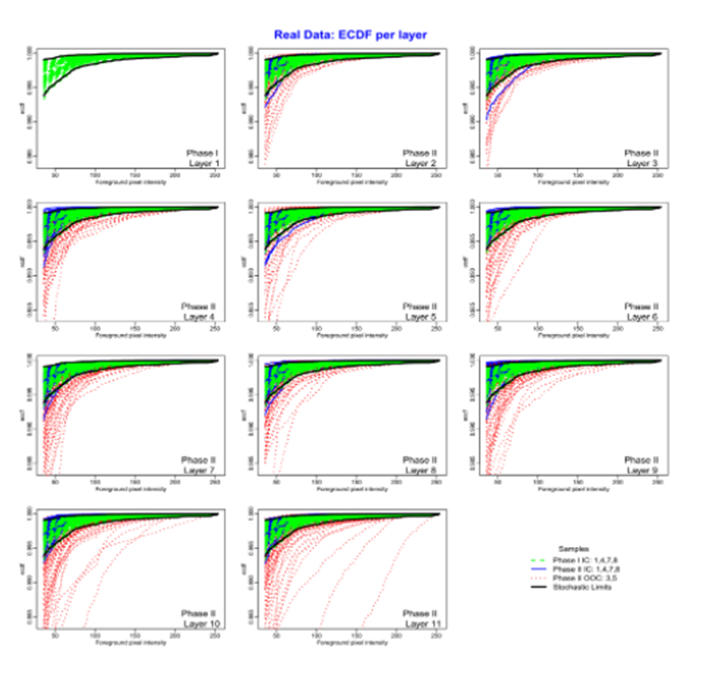

Image based statistical process monitoring via partial first order stochastic dominance

Tsiamyrtzis, P., Grasso, M. L. G., & Colosimo, B. M.

Quality Engineering, 34(1), 96-124

https://www.tandfonline.com/doi/abs/10.1080/08982112.2021.2008974

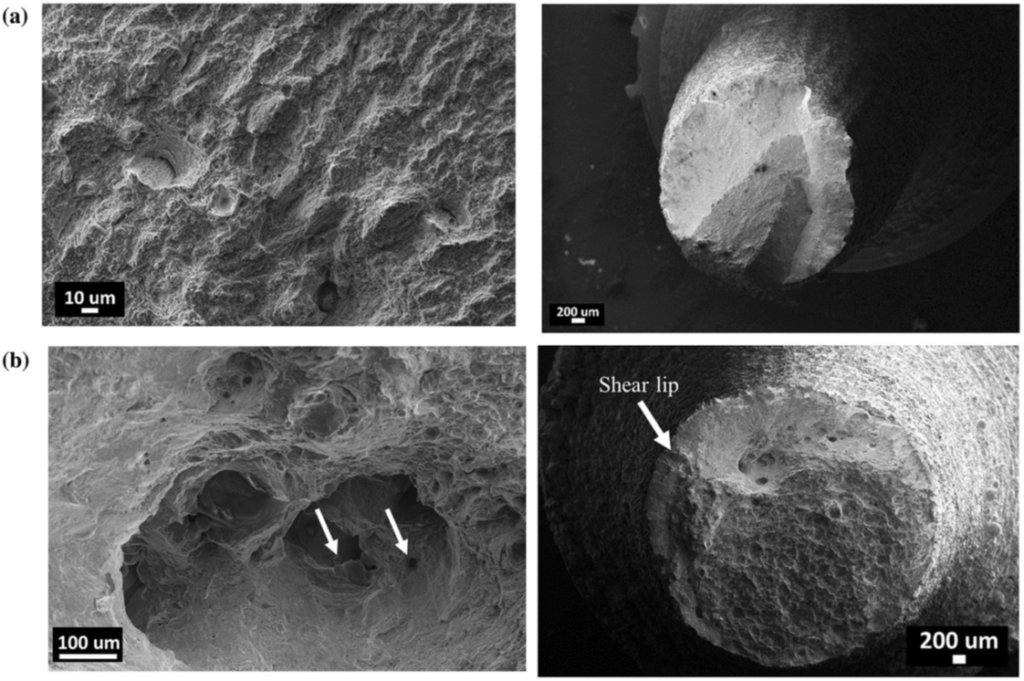

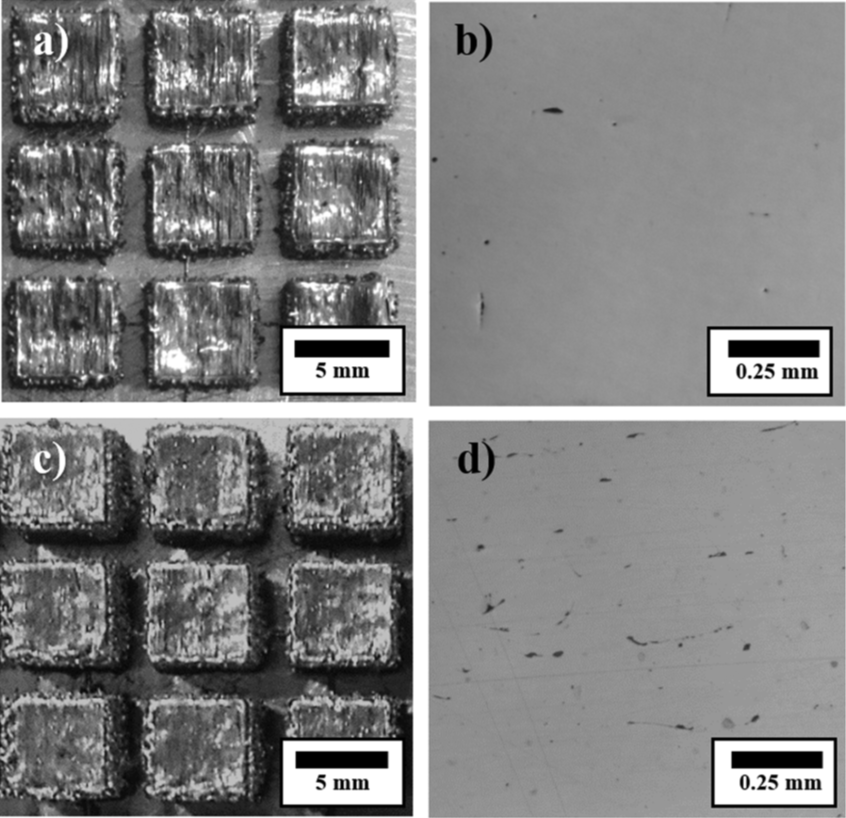

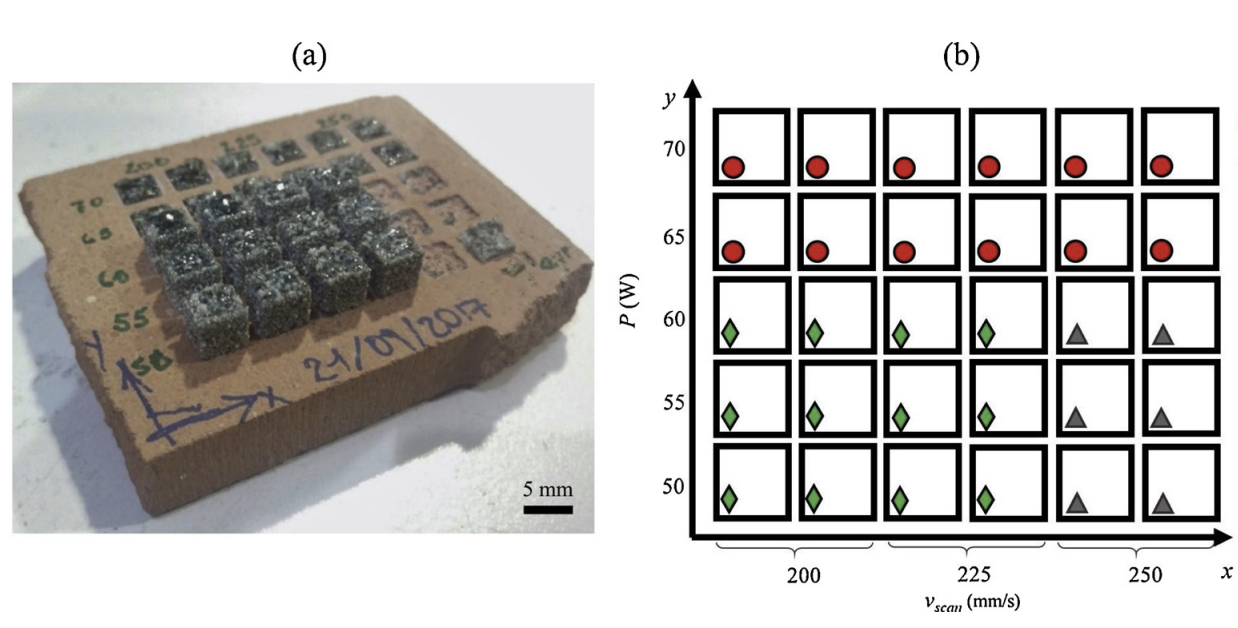

The effect of energy density and porosity structure on tensile properties of 316L stainless steel produced by laser powder bed fusion

S. Cacace, L. Pagani, B. M. Colosimo, and Q. Semeraro

Progress in Additive Manufacturing, vol. c, no. 0123456789

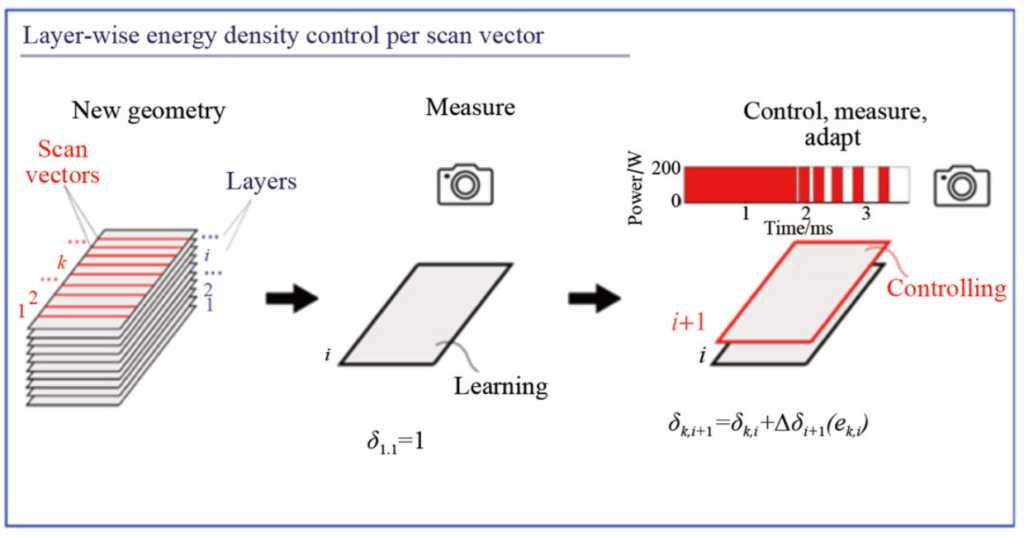

A novel paradigm for feedback control in LPBF: layer-wise correction for overhang structures

E. Vasileska, A. G. Demir, B. M. Colosimo, and B. Previtali

Advanced Manufacturing

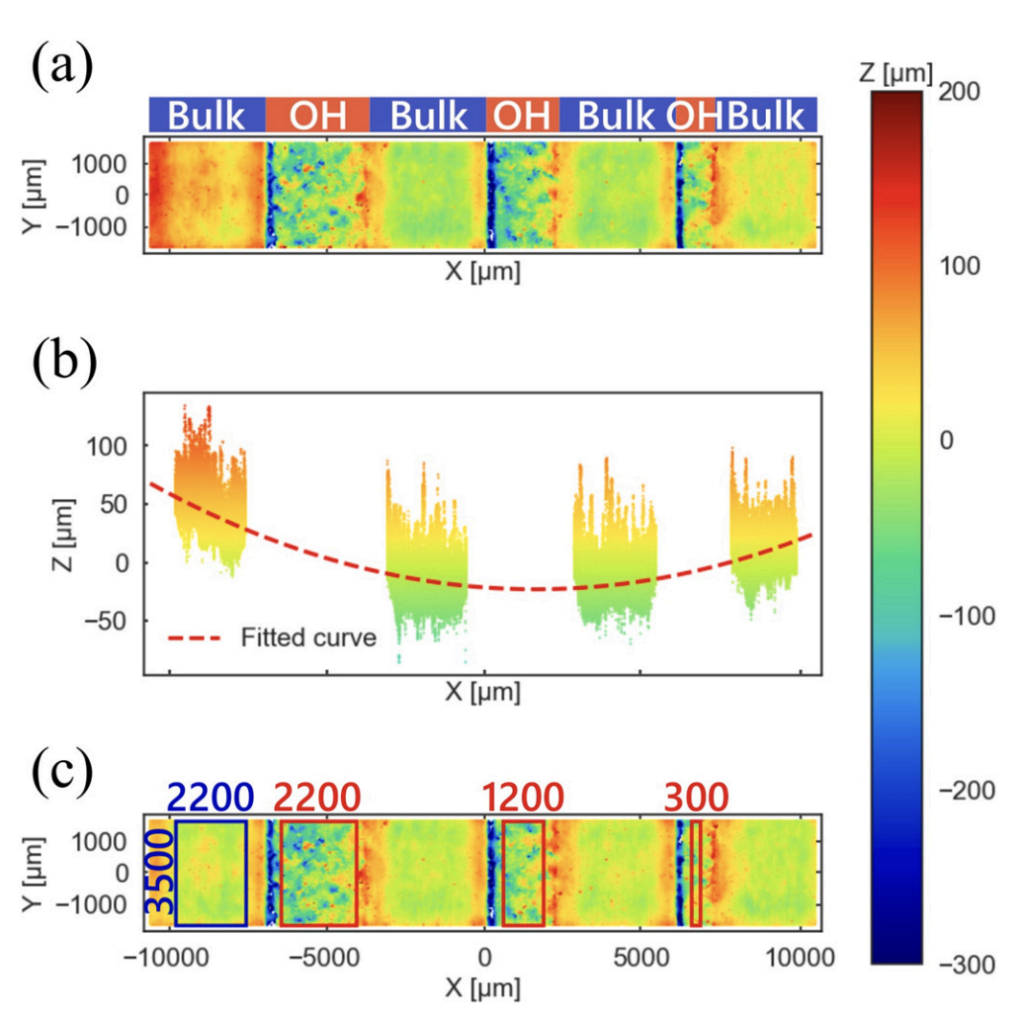

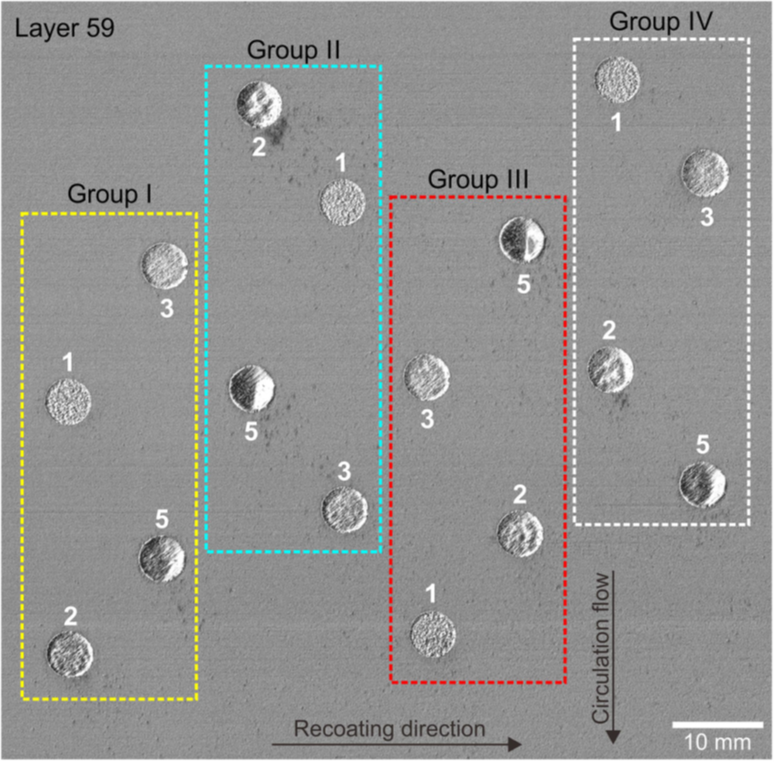

Predicting build density in L-PBF through in-situ analysis of surface topography using powder bed scanner technology

Q. Lu, M. Grasso, T. P. Le, and M. Seita

Additive Manufacturing, vol. 51, p. 102626

Compression Behavior of EBM Printed Auxetic Chiral Structures

TsK. Gunaydin, H. S. Türkmen, A. Airoldi, M. Grasso, G. Sala, and A. M. Grande

Materials (Basel), vol. 15, no. 4, pp. 1–21

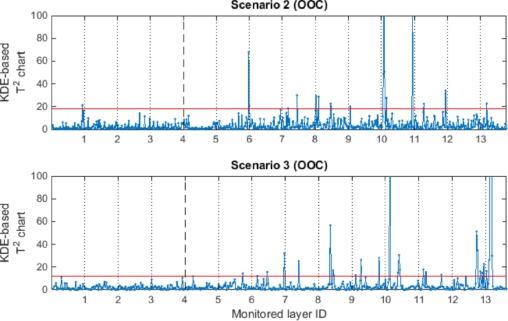

Real-time detection of clustered events in video-imaging data with applications to additive manufacturing

H. Yan, M. Grasso, K. Paynabar, and B. M. Colosimo

IISE Transactions, vol. 54, no. 5, pp. 464–480

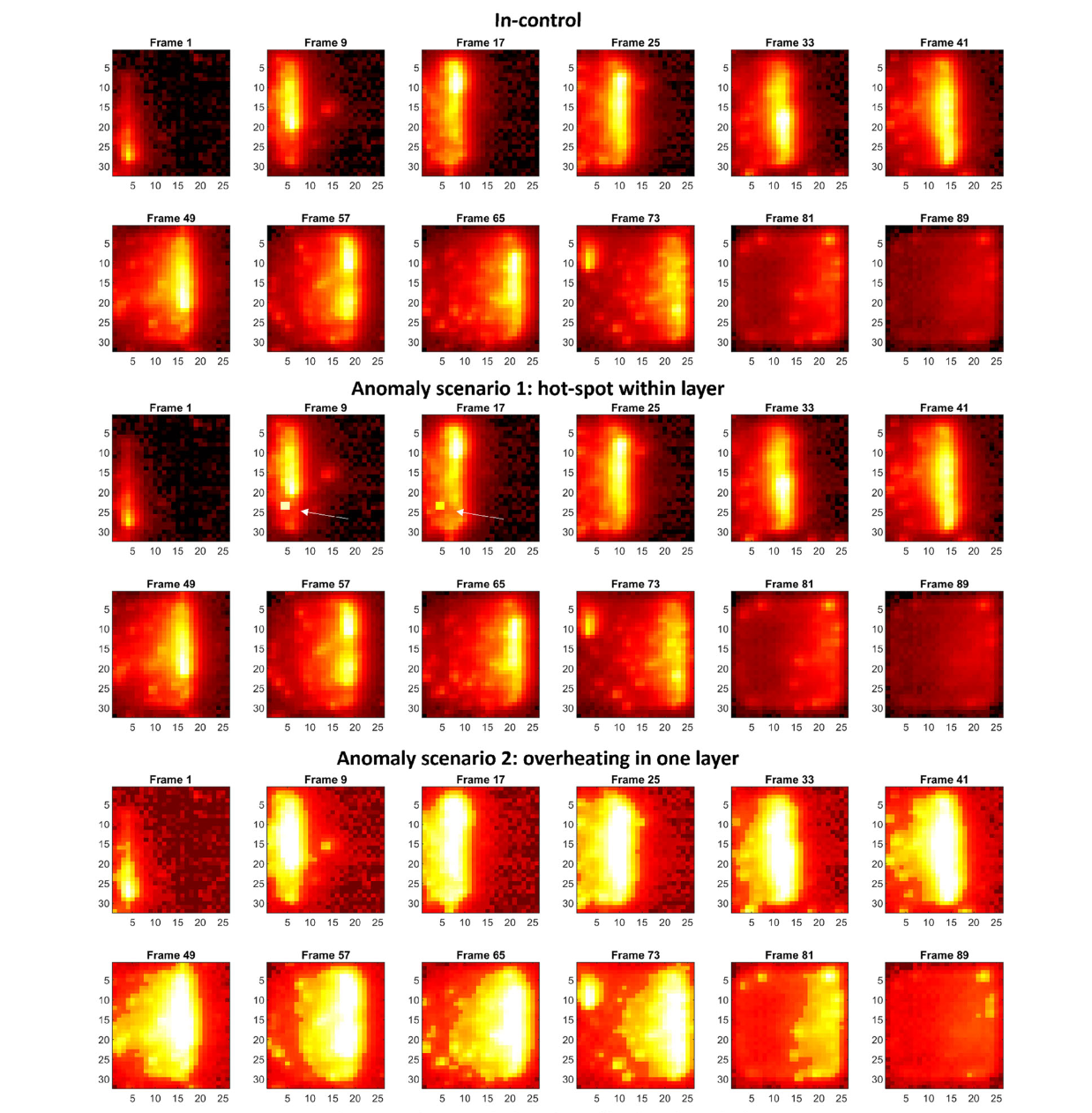

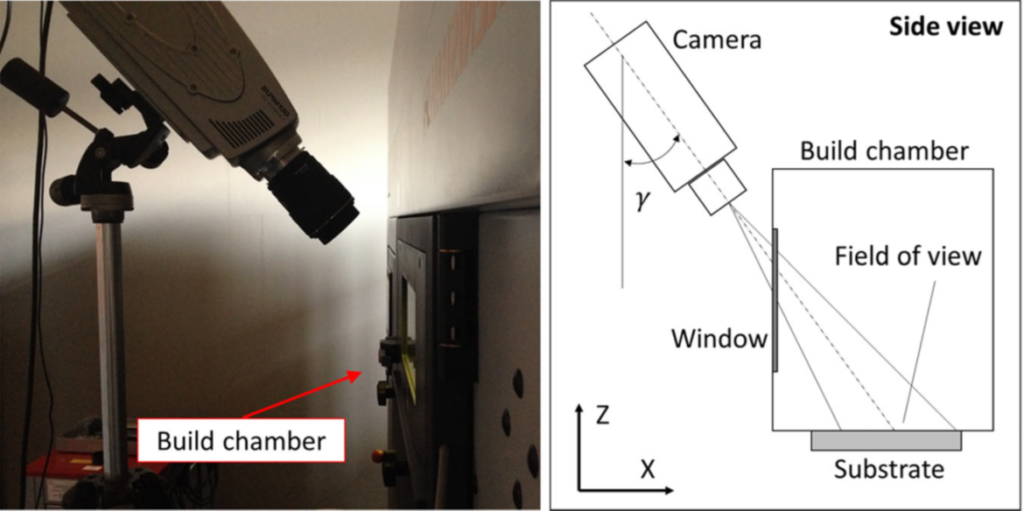

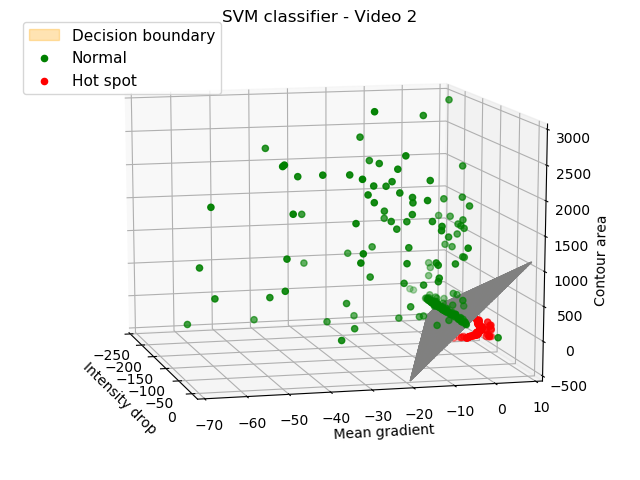

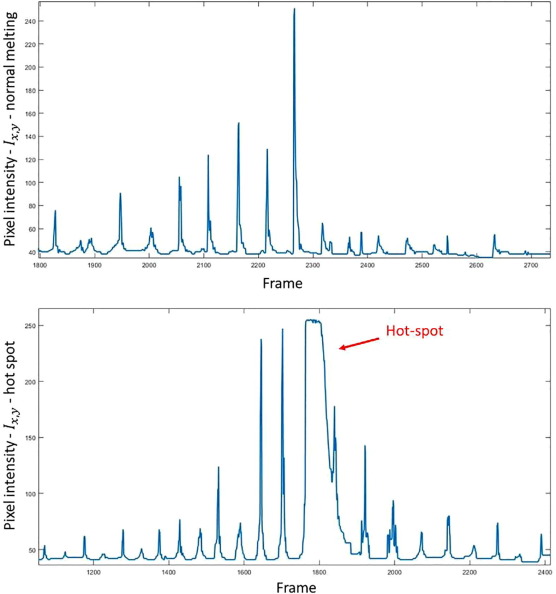

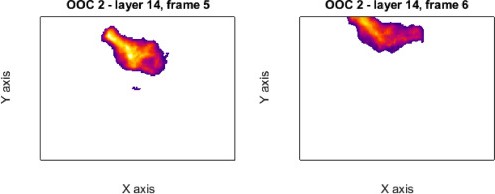

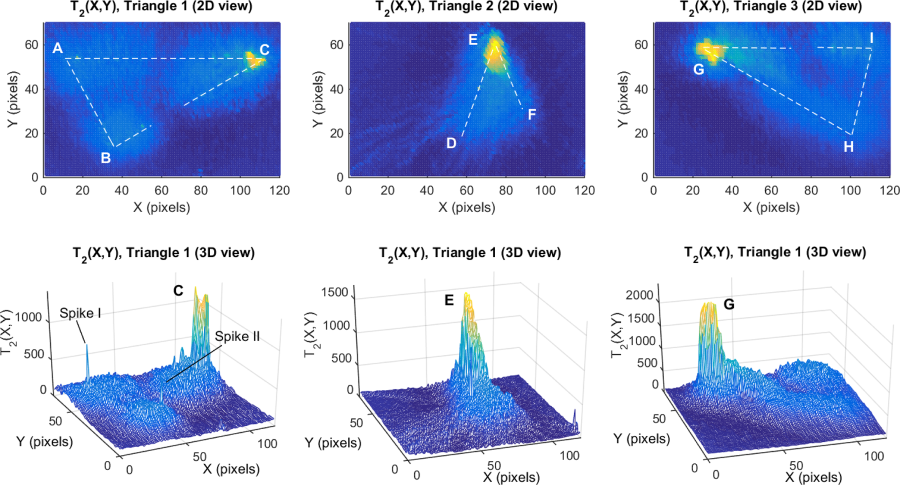

Towards real-time in-situ monitoring of hot-spot defects in L-PBF: a new classification-based method for fast video-imaging data analysis

Bugatti, M., Colosimo, B.M.

Journal of Intellingent Manufacturing, vol. 33, no. 1, pp. 293–309, 2022

Enabling multi-material gradient structure in laser powder bed fusion

A. G. Demir, J. Kim, F. Caltanissetta, A. J. Hart, C. C. Tasan, B. Previtali and B. M. Colosimo

Journal of Materials Processing Technologies, vol. 301

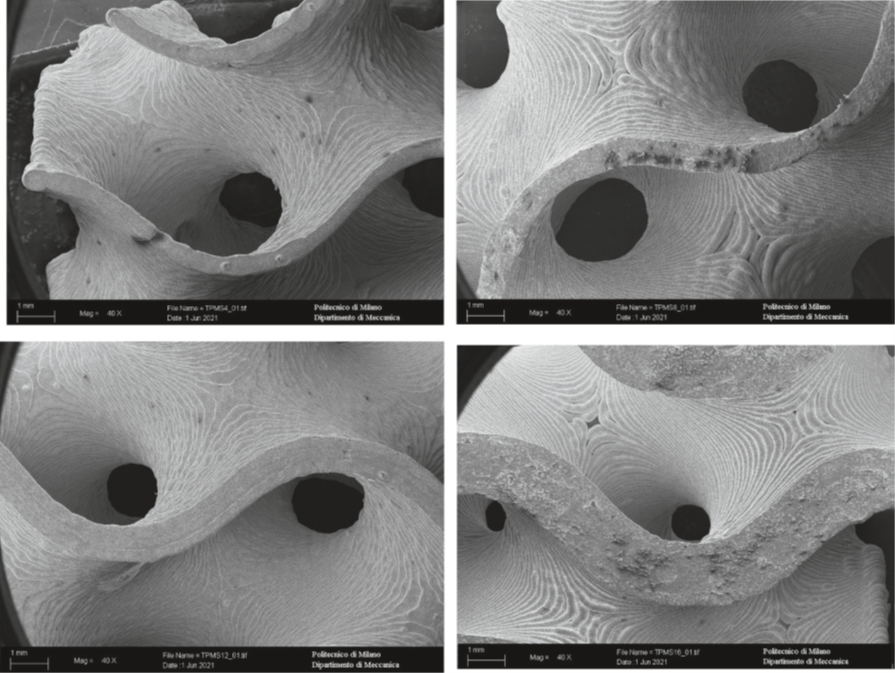

A new solution for assessing the printability of 17-4 PH gyroids produced via extrusion-based metal AM

P. Parenti, D. Puccio, B. M. Colosimo, and Q. Semeraro

Journal of Manufacturing Processes, vol. 74, no. January, pp. 557–572

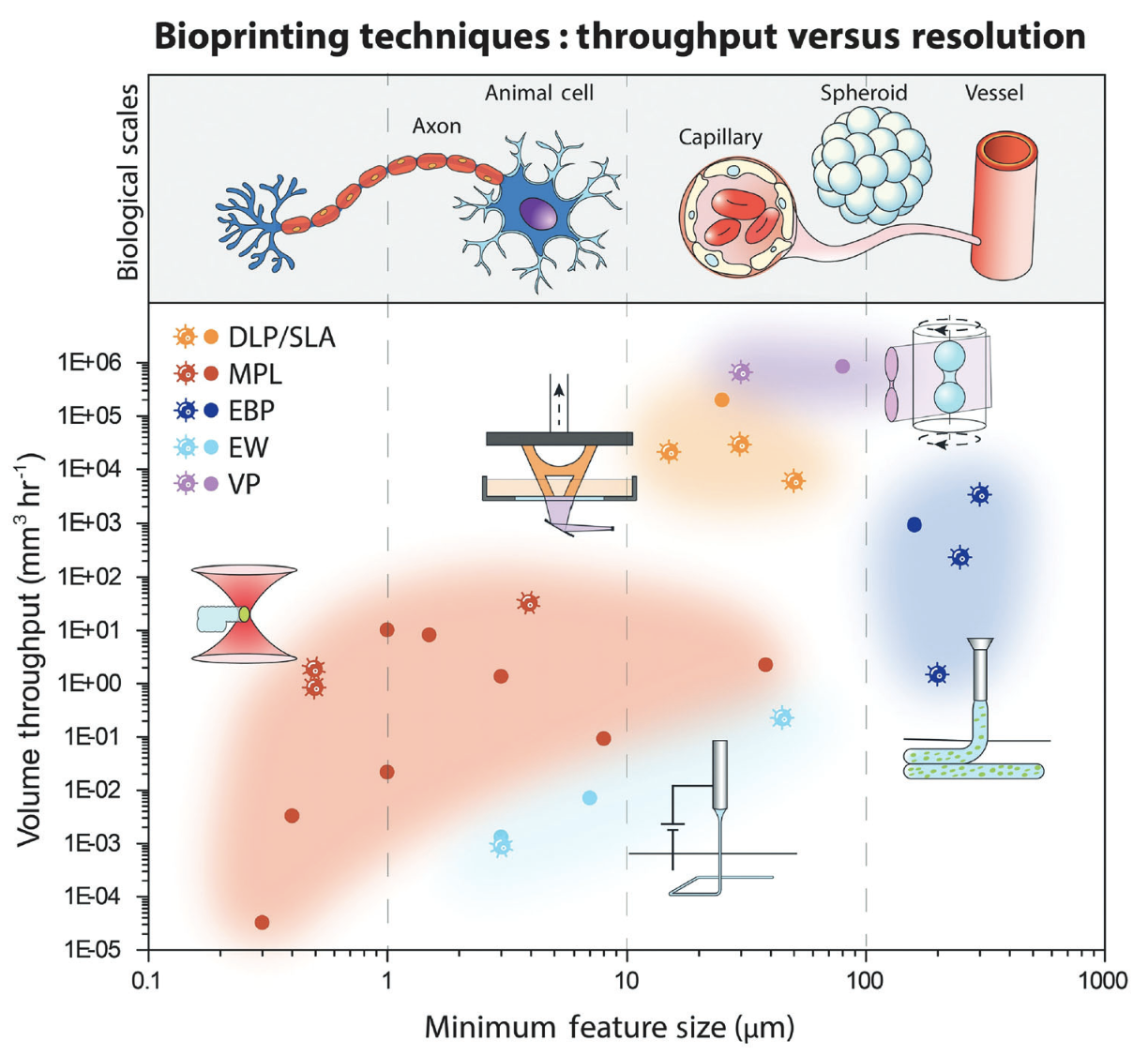

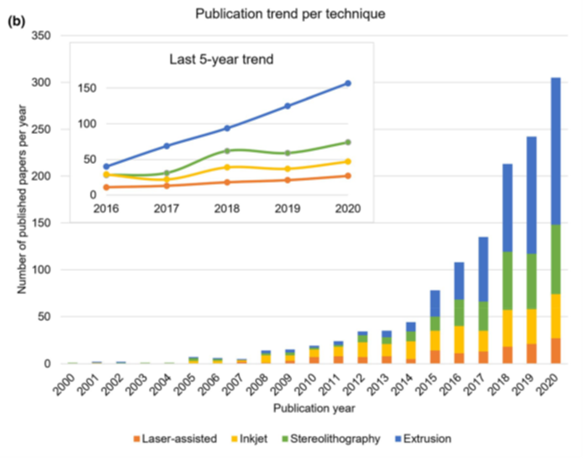

3D bioprinting: current status and trends—a guide to the literature and industrial practice

S. Santoni, S. G. Gugliandolo, M. Sponchioni, D. Moscatelli, and B. M. Colosimo

Bio-Design Manufacturing, vol. 5, no. 1, pp. 14–42

2021

Image based Statistical Process Monitoring via Partial

First Order Stochastic Dominance

Tsiamyrtzis, P., Grasso, M., Colosimo, B.M.

Quality Engineering, vol. 34, no. 1, pp. 96–124

Available Dataset:

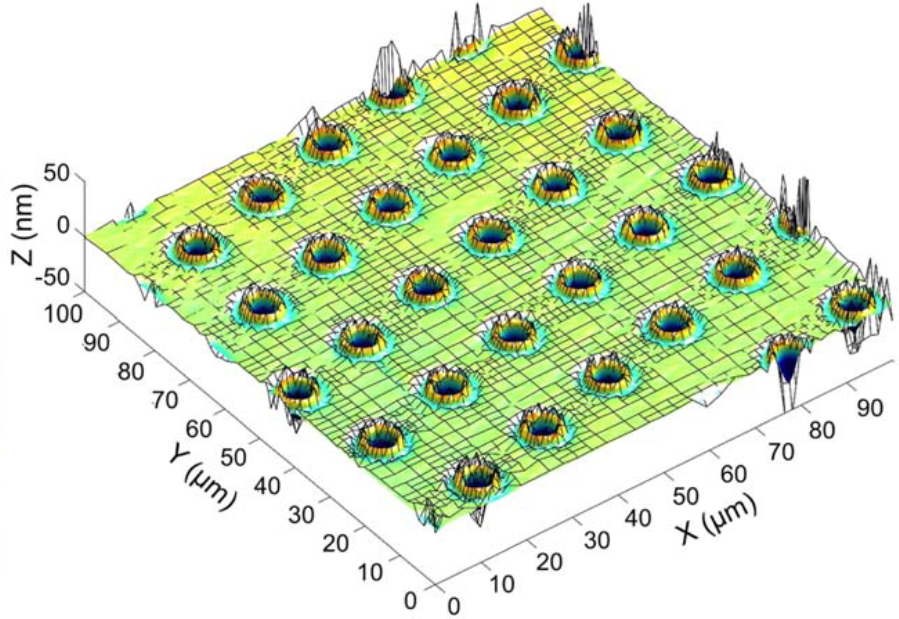

Characterisation of freeform, structured surfaces in T-spline spaces and its applications

J. Wang, R. Zou, B. M. Colosimo, W. Lu, L. Xu, and X. J. Jiang

Surface Topography: Metrology and Properties, vol. 9, no. 2

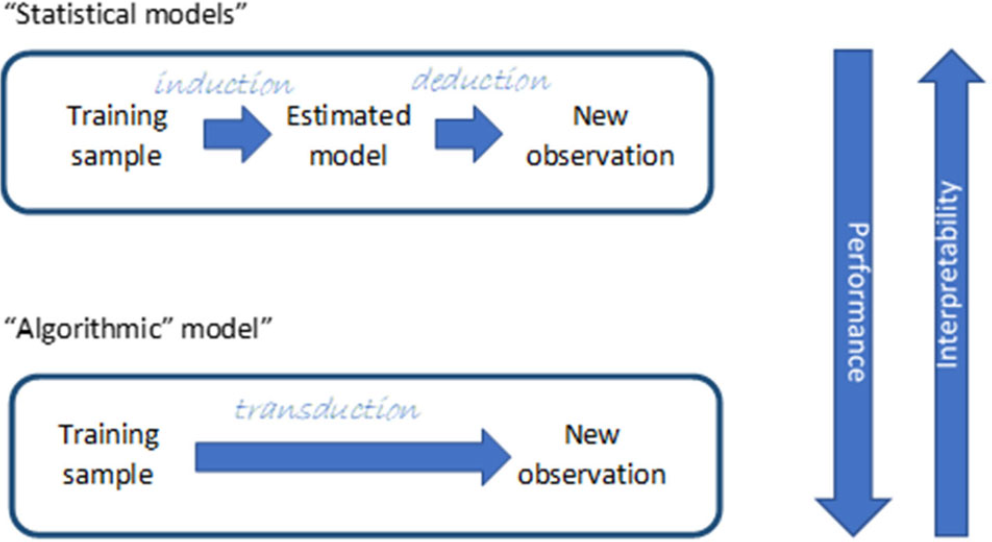

Artificial intelligence and statistics for quality technology: an introduction to the special issue

B. M. Colosimo, E. del Castillo, L. A. Jones-Farmer, and K. Paynabar

Journal of Quality Technology, vol. 53, no. 5, pp. 443–453

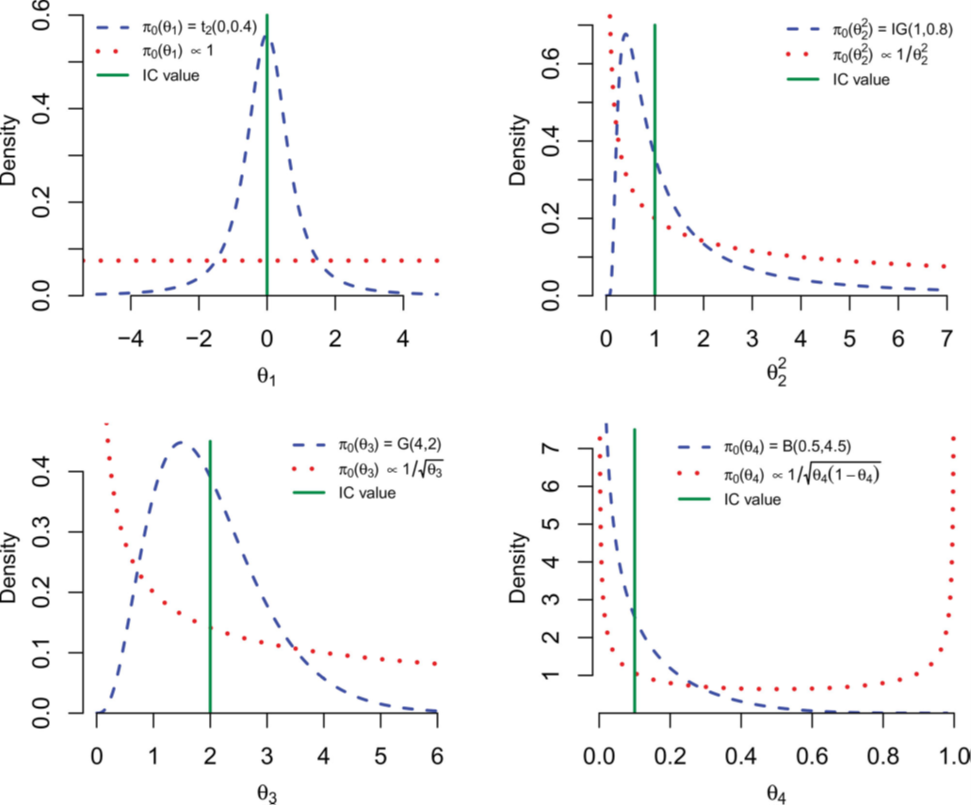

Predictive Control Charts (PCC): A Bayesian approach in online monitoring of short runs

K. Bourazas, D. Kiagias, and P. Tsiamyrtzis

Journal of Quality Technology, pp. 1–35

In situ monitoring of powder bed fusion homogeneity in electron beam melting

M. Grasso

Materials (Basel), vol. 14, no. 22

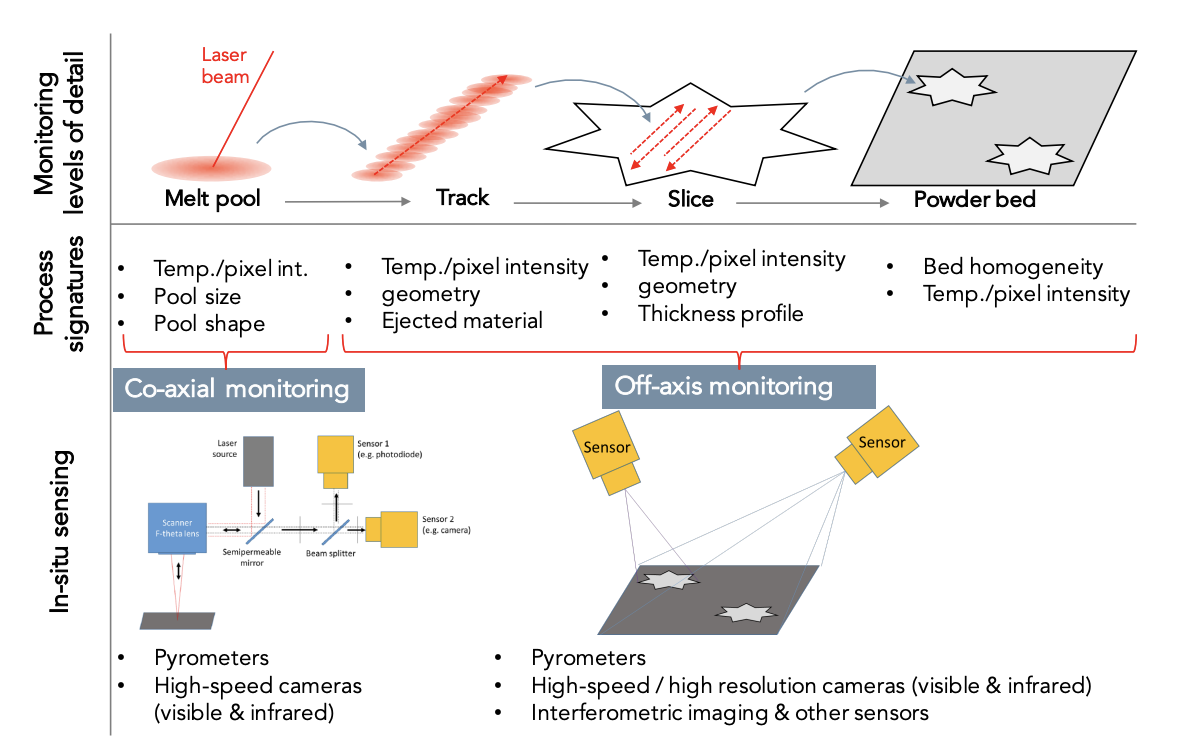

In-situ measurement and monitoring methods for metal powder bed fusion – an updated review

M. Grasso, A. Remani, A. Dickins, B. M. Colosimo, and R. K. Leach

Meas. Sci. Technol., vol. 32, no. 11

Direct laser additive manufacturing of high performance oxide ceramics: a state-of-the-art review

Pfeiffer, S., Florio, K., Puccio, D., Grasso, M., Colosimo, B. M., Aneziris, C. G., Wegener, K., Graule, T.

Journal of the European Ceramic Society, 41(13), 6087-6114.

Process Characterization and Analysis of Ceramic Powder Bed Fusion

Florio, K., Puccio, D., Pfeiffer, S., Verga, F., Grasso, M., Colosimo, B.M., Graule, T., Wegener, K.

The International Journal of Advanced Manufacturing Technology, 117, 2105-2116

2020

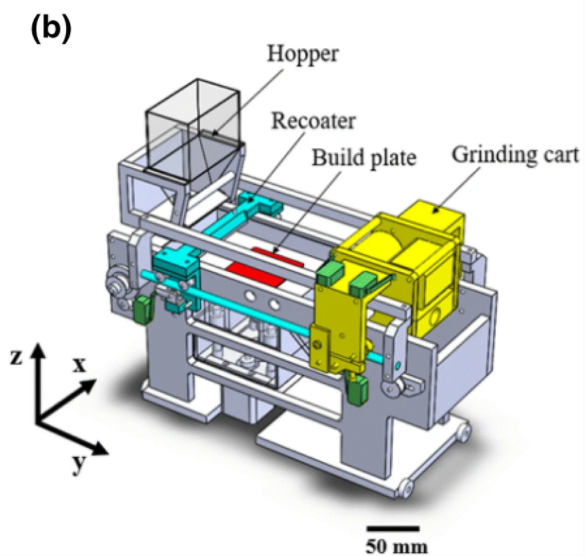

Penelope: a novel prototype for in-situ defect removal in LPBF

Colosimo, B.M., Grossi, E., Caltanissetta, F., Grasso, M.

JOM 72, 1332-1339

https://link.springer.com/article/10.1007/s11837-019-03964-0

Automated layerwise detection of geometrical distortions in laser powder bed fusion

Pagani, L., Grasso, M., Scott, P. J., & Colosimo, B. M.

Additive Manufacturing, 36, 101435

Powder bed irregularity and hot-spot detection in Electron Beam Melting by means of in-situ video imaging

Grasso, M., Valsecchi, G., Colosimo, B.M.

Manufacturing Letters, 24, 47-51

A cost model for the economic evaluation of in-situ monitoring tools in metal additive manufacturing

Colosimo, B.M., Cavalli, S., Grasso, M.

International Journal of Production Economics, 223, 107532

Layer-wise control of selective laser melting by means of inline melt pool area measurements

Vasileska, E., Demir, A. G., Colosimo, B. M., & Previtali, B.

Journal of Laser Applications, 32(2).

Determining the feasible conditions for processing lunar regolith simulant via laser powder bed fusion

Caprio, L., Demir, A. G., Previtali, B., & Colosimo, B. M.

Additive Manufacturing, 32, 101029.

2019

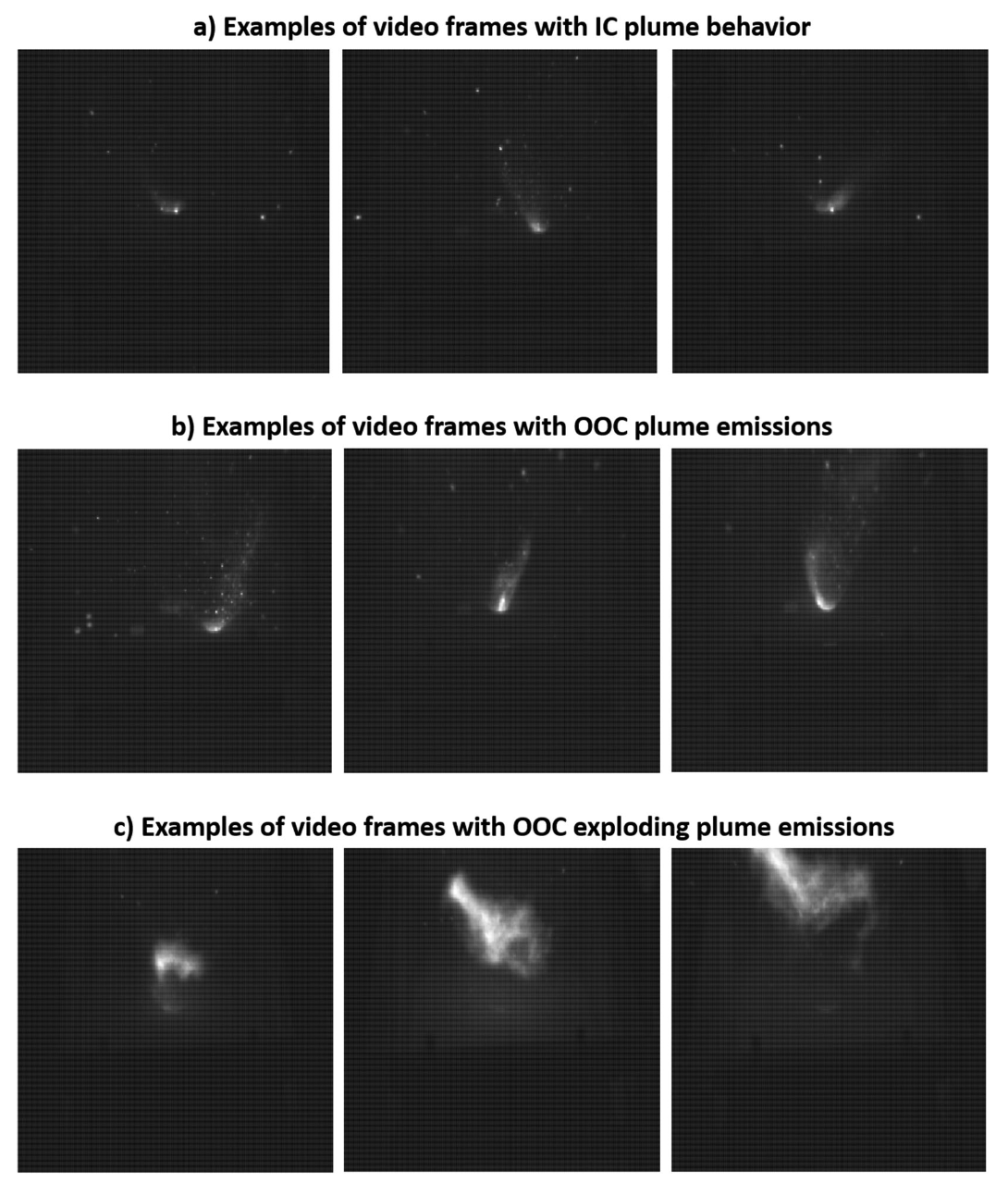

A Statistical Learning Method for Image-based Monitoring of the Plume Signature in Laser Powder Bed Fusion

Grasso, M., Colosimo, B.M.

Robotics and Computer-Integrated Manufacturing, 57, 103-115

Prescriptive Data-Analytical Modeling of Laser Powder Bed Fusion Processes

He, L., Grasso, M., Colosimo, B.M., Huang, Q.

Journal of Manufacturing Science and Technology, 141(1): 011008

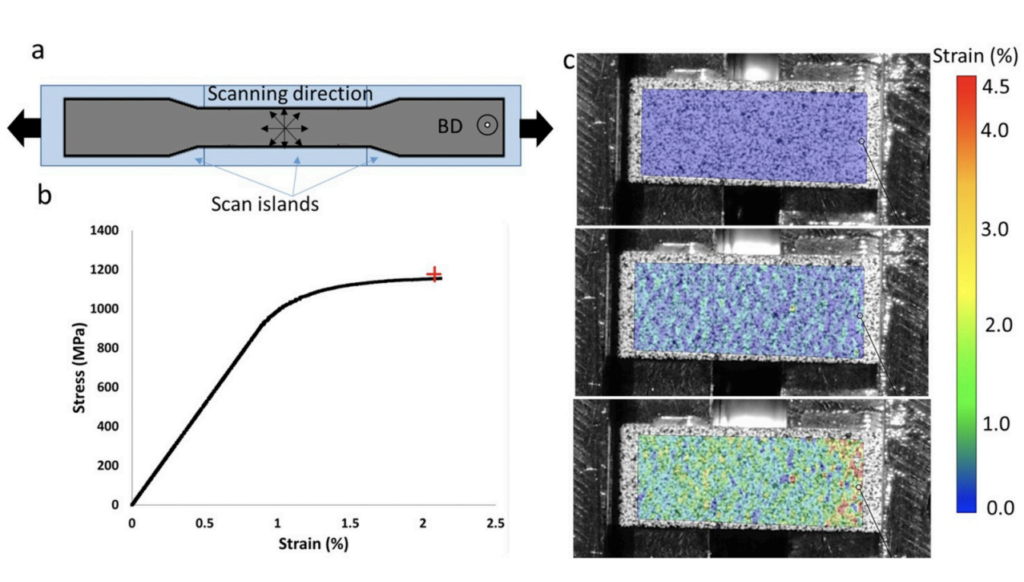

Deformation and failure mechanisms of Ti–6Al–4V as built by selective laser melting

Moridi, A., Demir, A. G., Caprio, L., Hart, A. J., Previtali, B., & Colosimo, B. M.

Materials Science and Engineering: A, 768, 138456

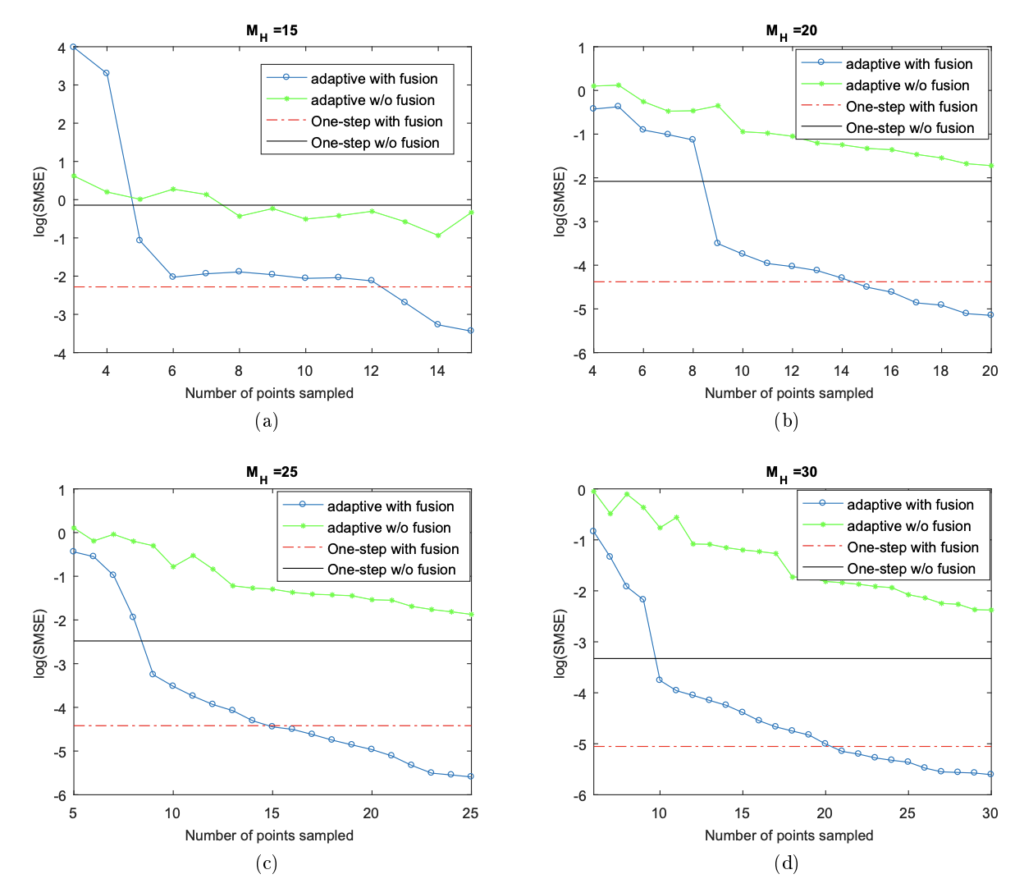

An adaptive fused sampling approach of high-accuracy data in the presence of low-accuracy data

Gahrooei, M. R., Paynabar, K., Pacella, M., & Colosimo, B. M.

IISE Transactions, 51(11), 1251-1264.

https://www.tandfonline.com/doi/full/10.1080/24725854.2018.1540901

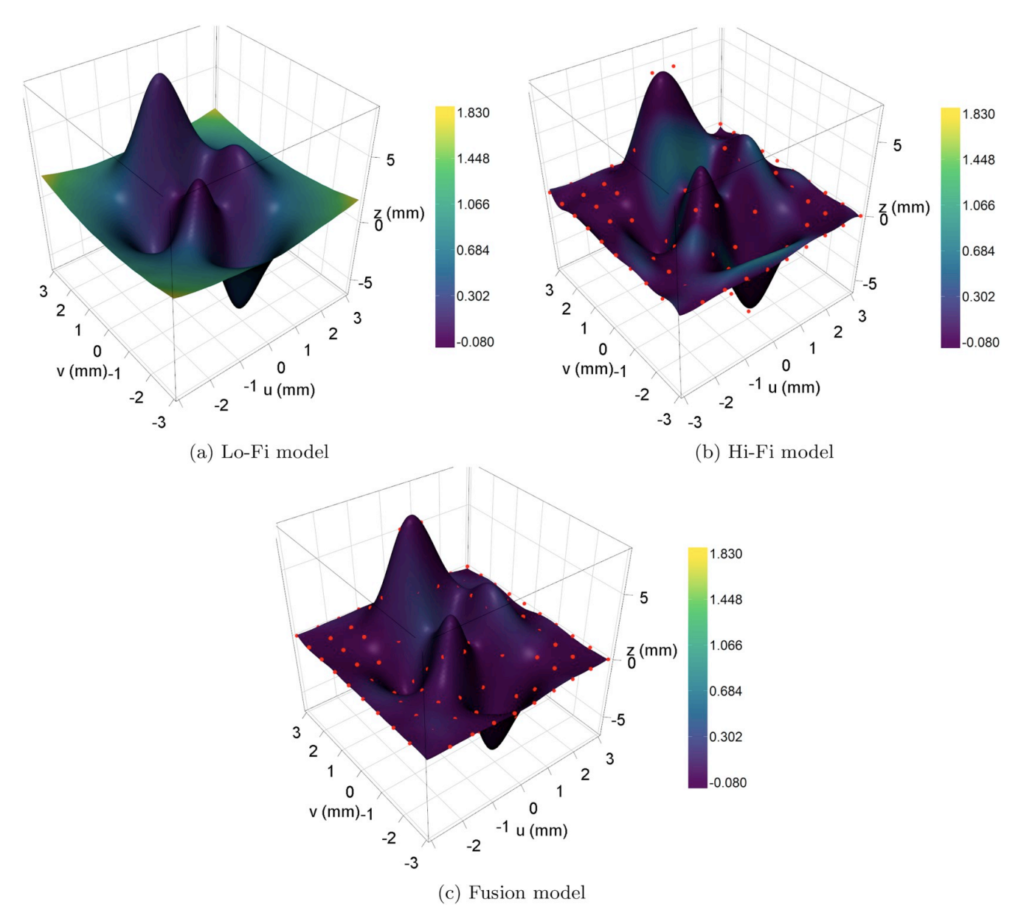

Fast hierarchical fusion model based on least squares B-splines approximation

Pagani, L., Wang, J., Colosimo, B. M., Jiang, X., & Scott, P. J.

Precision Engineering 60 (2019): 570-586

2018

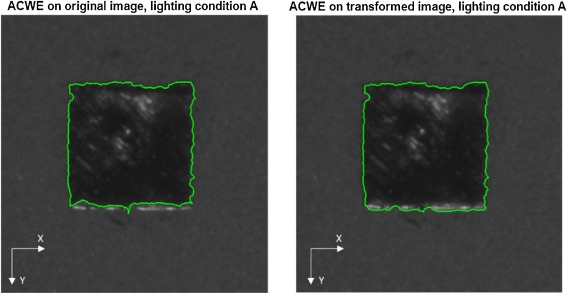

Characterization of In-Situ Measurements based on Layerwise Imaging in Laser Powder Bed Fusion

Caltanissetta F., Grasso M., Petrò S., Colosimo, B. M.

Additive Manufacturing, 24, 183-199

https://www.sciencedirect.com/science/article/pii/S2214860418305785

Spatially weighted PCA for monitoring video image data with application to additive manufacturing

Colosimo, B.M., Grasso, M.

Journal of Quality Technology, 50(4), 391-417

https://www.tandfonline.com/doi/abs/10.1080/00224065.2018.1507563

Available dataset: https://doi.org/10.6084/m9.figshare.7092863.v1

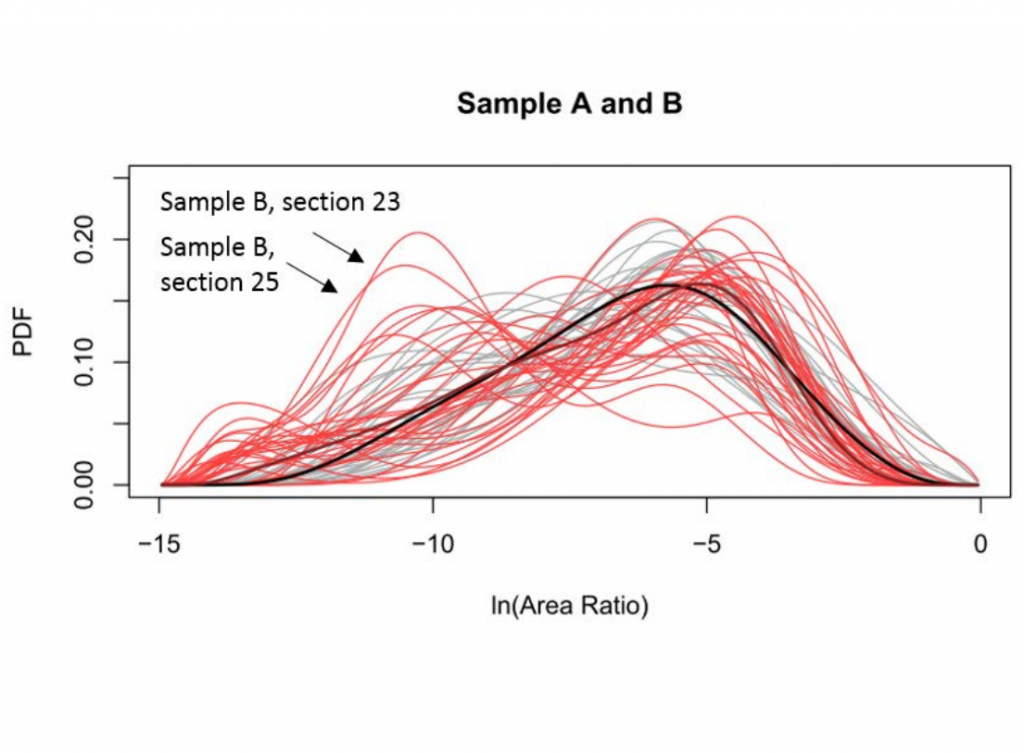

Profile Monitoring of Probability Density Functions for Image Data via Simplicial Functional Principal Component Analysis

Menafoglio A., Grasso M., Secchi P., Colosimo B.M.

Technometrics, 60(4), 497-510

https://www.tandfonline.com/doi/abs/10.1080/00401706.2018.1437473

In-situ Monitoring of Selective Laser Melting of Zinc Powder via Infrared Imaging of the Process Plume

Grasso, M., Demir, A.G., Previtali, B., Colosimo, B.M.

Robotics and Computer-Integrated Manufacturing, 49, 229-239

https://www.sciencedirect.com/science/article/pii/S0736584517300583

Domain-Selective Functional ANOVA for Supervised Statistical Profile Monitoring of Signal Data

Pini A., Vantini S., Colosimo B.M., Grasso M.

Journal of the Royal Statistical Society: Series C (Applied Statistics), 67(1), 55-81

Multilinear principal component analysis for statistical modeling of cylindrical surfaces: a case study

Pacella, M., & Colosimo, B. M.

Quality Technology & Quantitative Management, 15(4), 507-525

https://www.tandfonline.com/doi/full/10.1080/16843703.2016.1226710

Opportunities and challenges of quality engineering for additive manufacturing

Colosimo, B. M., Huang, Q., Dasgupta, T., & Tsung, F.

Journal of Quality Technology, 50(3), 233-252

https://www.tandfonline.com/doi/full/10.1080/00224065.2018.1487726

Modeling and monitoring methods for spatial and image data

Colosimo, B. M.

Quality Engineering, 30(1), 94-111

https://www.tandfonline.com/doi/abs/10.1080/08982112.2017.1366512

2017

On the use of spatter signature for in-situ monitoring of Laser Powder Bed Fusion

Repossini G., Laguzza V., Grasso M., Colosimo B.M.

Additive Manufacturing, 16, 35-48

https://www.sciencedirect.com/science/article/pii/S2214860416303402

Process Defects and In-situ Monitoring Methods in Metal Powder Bed Fusion: a Review

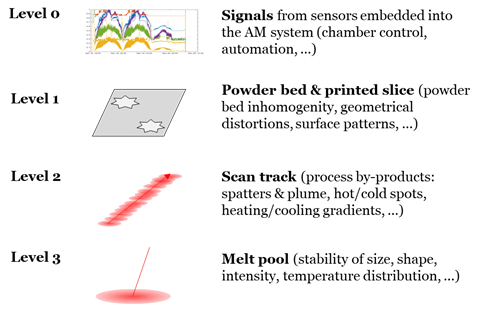

Grasso M., Colosimo B.M.

Measurement Science and Technology, 28(4), 1-25

https://iopscience.iop.org/article/10.1088/1361-6501/aa5c4f/meta

In-process Monitoring of Selective Laser Melting: Spatial Detection of Defects via Image Data Analysis

Grasso M., Laguzza V., Semeraro Q., Colosimo B.M.

Journal of Manufacturing Science and Engineering, 139(5), 051001-1 – 051001-16

A phase I multi-modelling approach for profile monitoring of signal data

Grasso, M., Colosimo, B. M., Tsung, F.

International Journal of Production Research, 55(15), 4354-4377

https://www.tandfonline.com/doi/abs/10.1080/00207543.2016.1251626

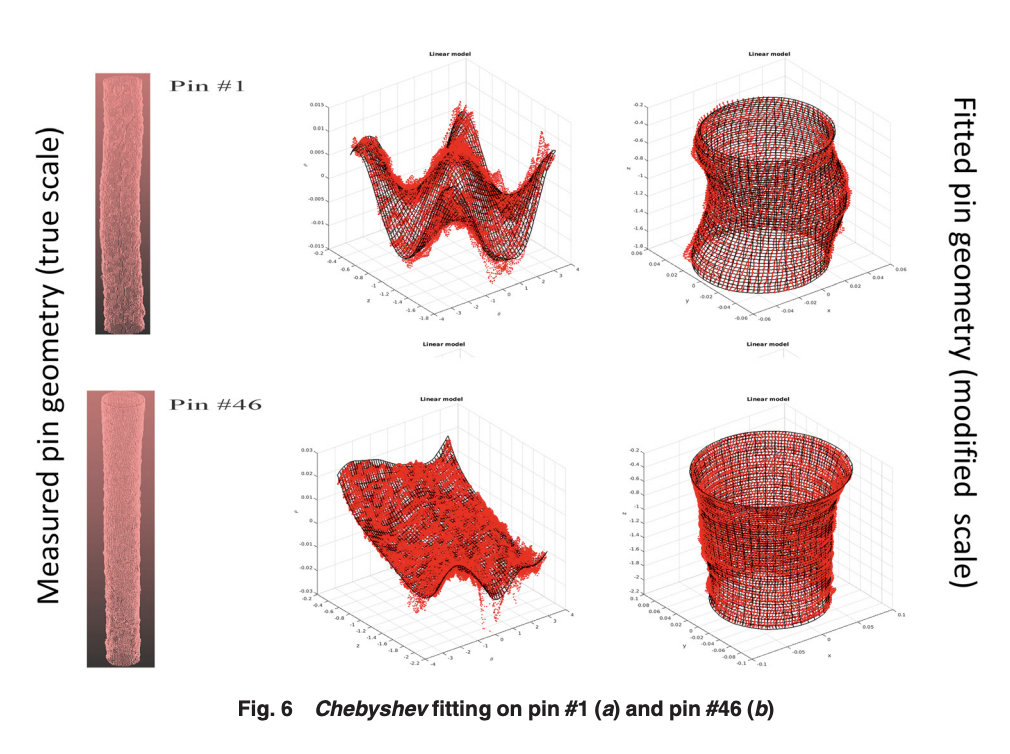

On the geometrical accuracy of high aspect ratio micromilled pins

Parenti, P., Pagani, L., Annoni, M., Colosimo, B. M., & Semeraro

Journal of Manufacturing Science and Engineering, 139(5), 051002

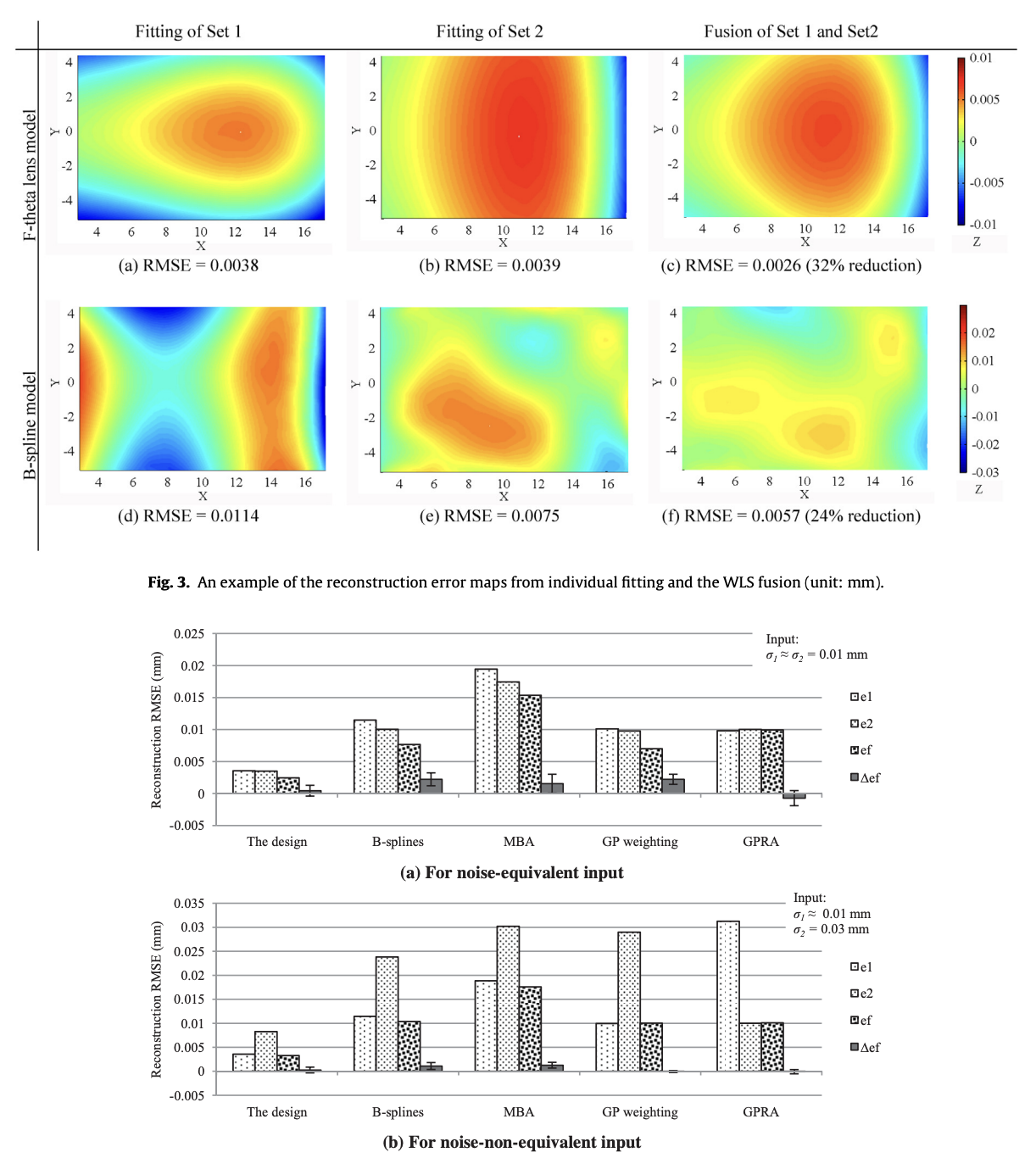

Study of weighted fusion methods for the measurement of surface geometry

Wang, J., Pagani, L., Leach, R. K., Zeng, W., Colosimo, B. M., & Zhou, L.

Precision Engineering, 47, 111-121.

2016

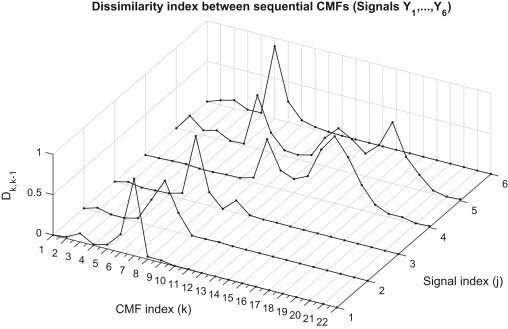

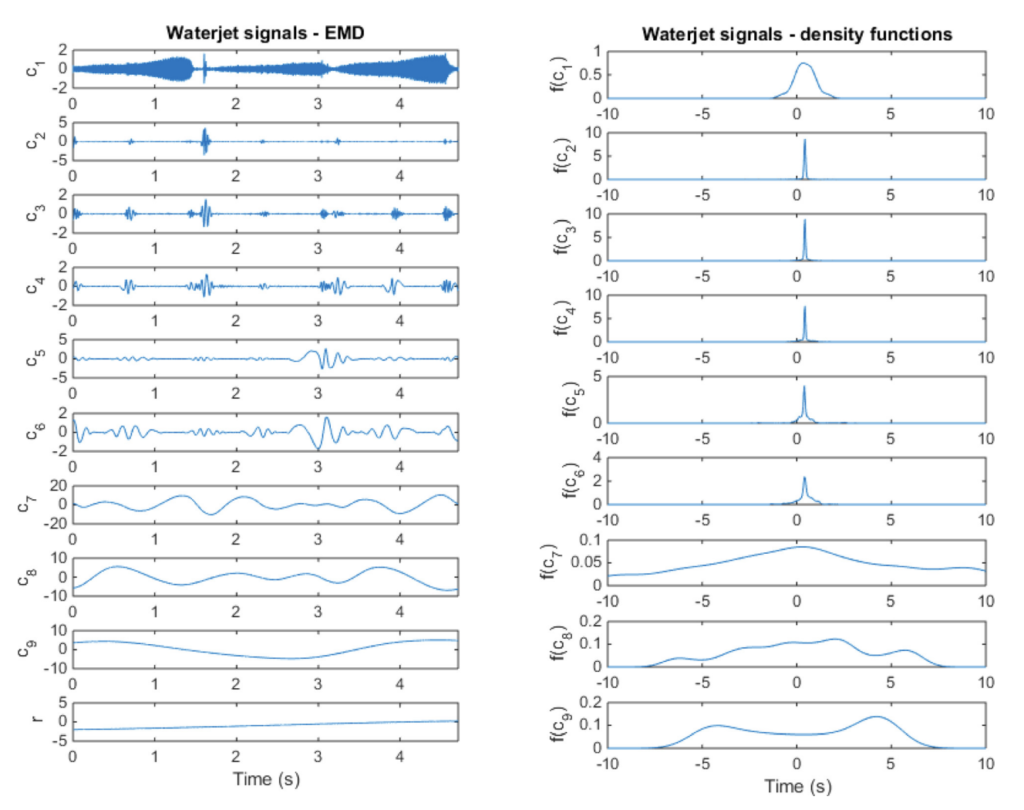

A Data-Driven Method to Enhance Vibration Signal Decomposition for Rolling Bearing Fault Analysis

Grasso M., Chatterton S., Pennacchi P., Colosimo B.M.

Mechanical Systems and Signal Processing, 81, 126-147

https://www.sciencedirect.com/science/article/pii/S0888327016001230

An Automated Approach to Enhance Multi-Scale Signal Monitoring of Manufacturing Processes

Grasso M., Colosimo B.M.

Journal of Manufacturing Science and Engineering, 138(5), 051003-1 – 051003-16

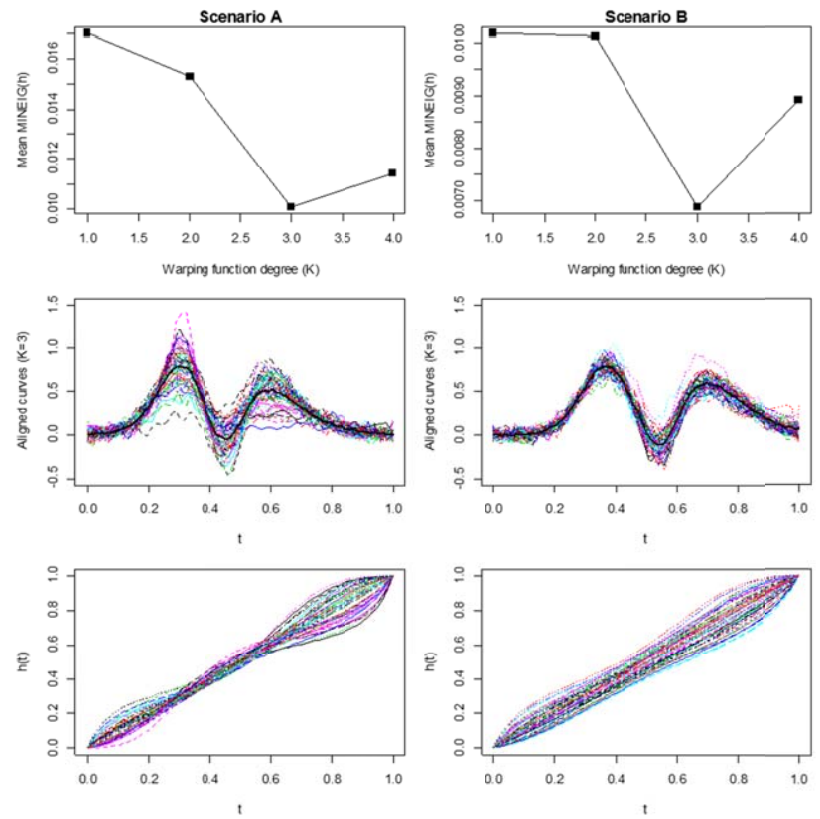

Using Curve Registration Information to Enhance Profile Monitoring of Signal Data

Grasso M., Menafoglio A., Colosimo B. M., Secchi P.

Journal of Quality Technology, 48(2), 99-127

https://www.tandfonline.com/doi/abs/10.1080/00224065.2016.11918154