2022

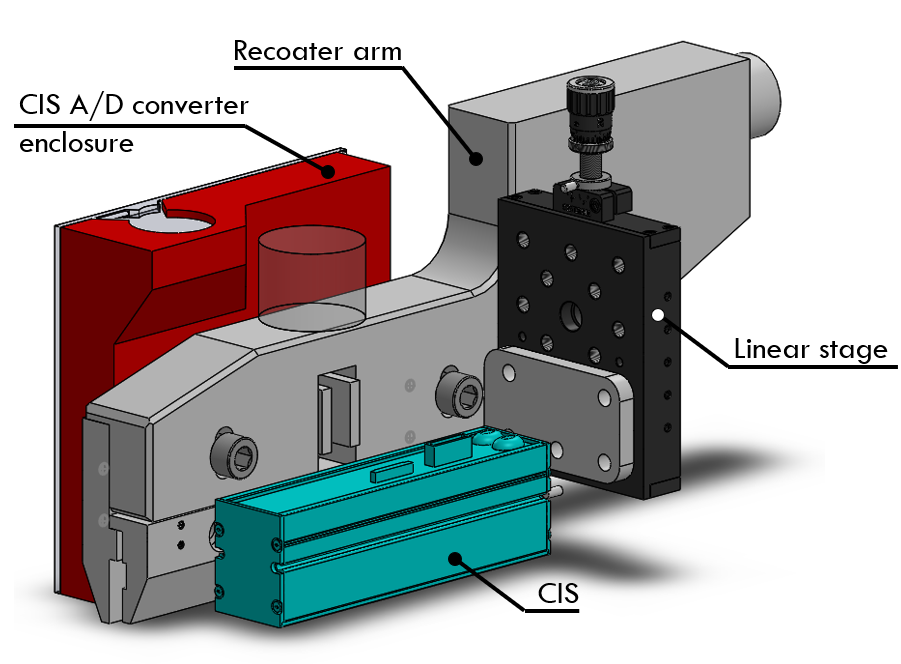

The intelligent recoater: A new solution for in-situ monitoring of geometric and surface defects in powder bed fusion

M. Bugatti and B. M. Colosimo

Additive Manufacturing Letters, Volume 3, 2022

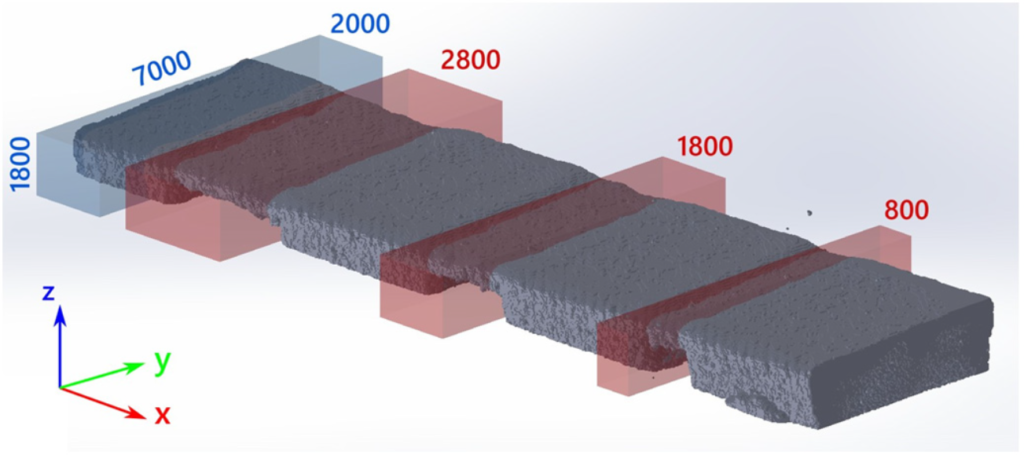

Effect of overhanging surfaces on the evolution of substrate topography and internal defects formation in laser powder bed fusion

M. Bugatti, Q. Semeraro, and B. M. Colosimo

Journal of Manufacturing Processes, vol. 77, no. November 2021, pp. 588–606

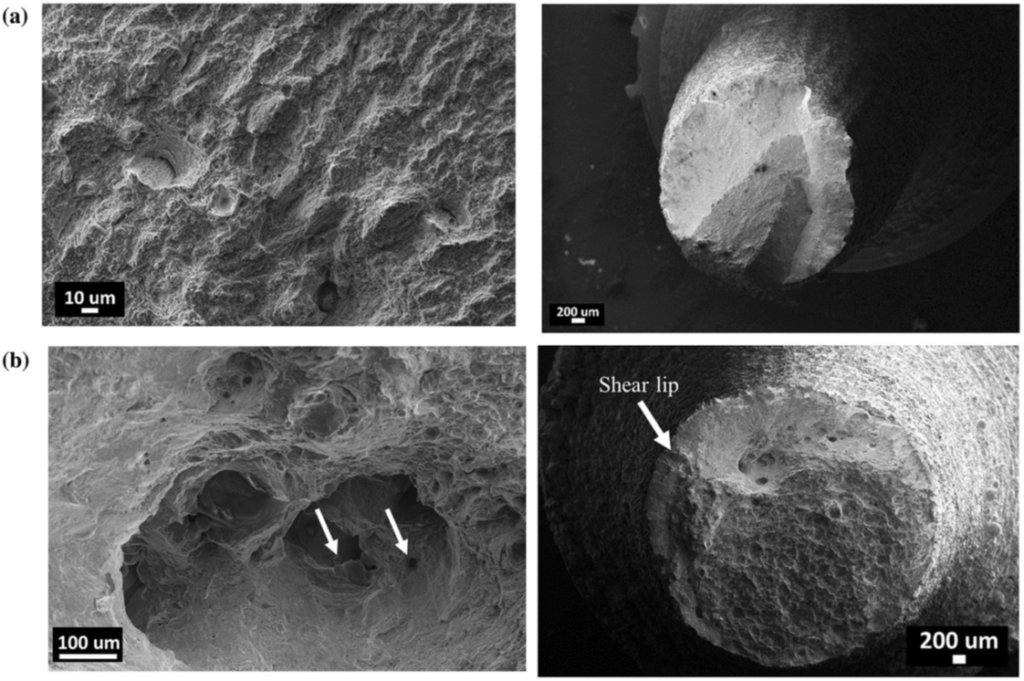

The effect of energy density and porosity structure on tensile properties of 316L stainless steel produced by laser powder bed fusion

S. Cacace, L. Pagani, B. M. Colosimo, and Q. Semeraro

Progress in Additive Manufacturing, vol. c, no. 0123456789

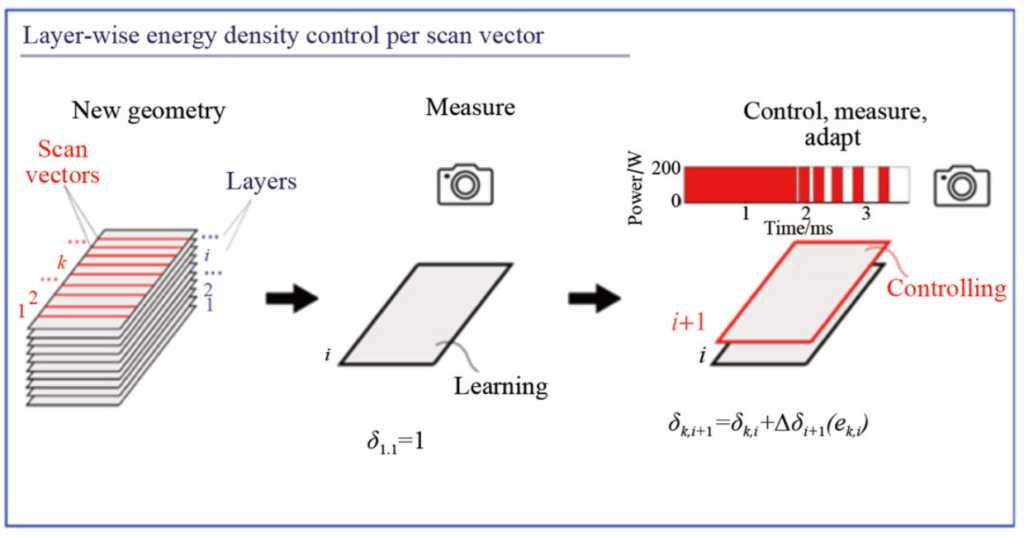

A novel paradigm for feedback control in LPBF: layer-wise correction for overhang structures

E. Vasileska, A. G. Demir, B. M. Colosimo, and B. Previtali

Advanced Manufacturing

Predicting build density in L-PBF through in-situ analysis of surface topography using powder bed scanner technology

Q. Lu, M. Grasso, T. P. Le, and M. Seita

Additive Manufacturing, vol. 51, p. 102626

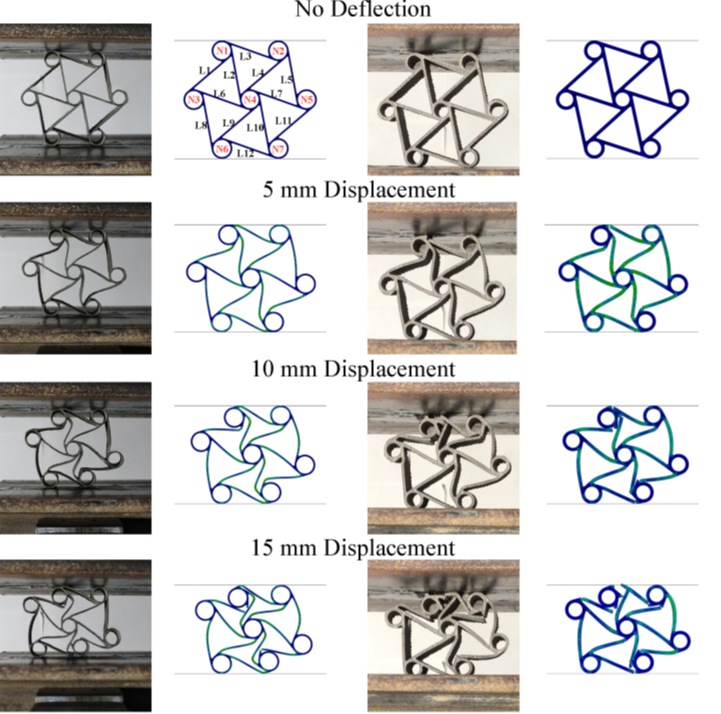

Compression Behavior of EBM Printed Auxetic Chiral Structures

TsK. Gunaydin, H. S. Türkmen, A. Airoldi, M. Grasso, G. Sala, and A. M. Grande

Materials (Basel), vol. 15, no. 4, pp. 1–21

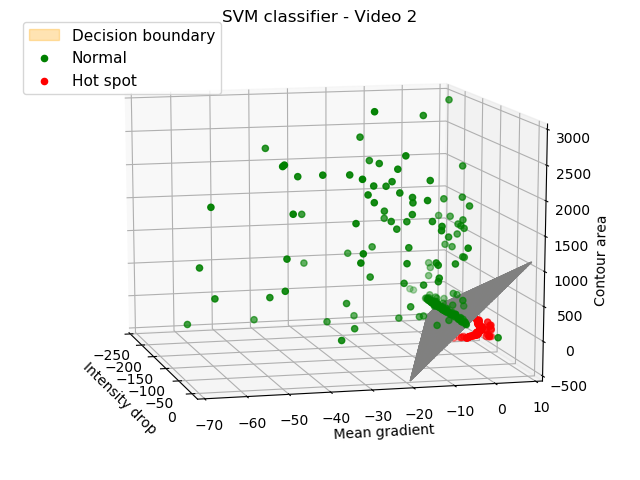

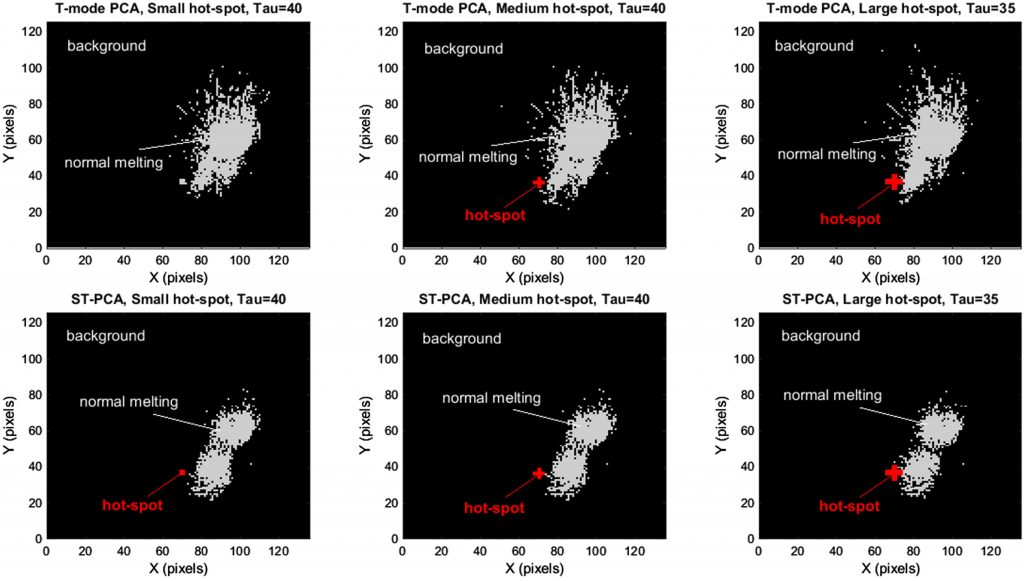

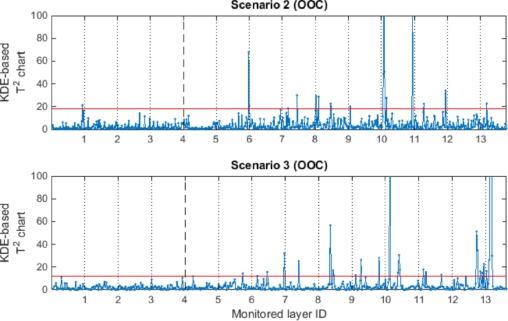

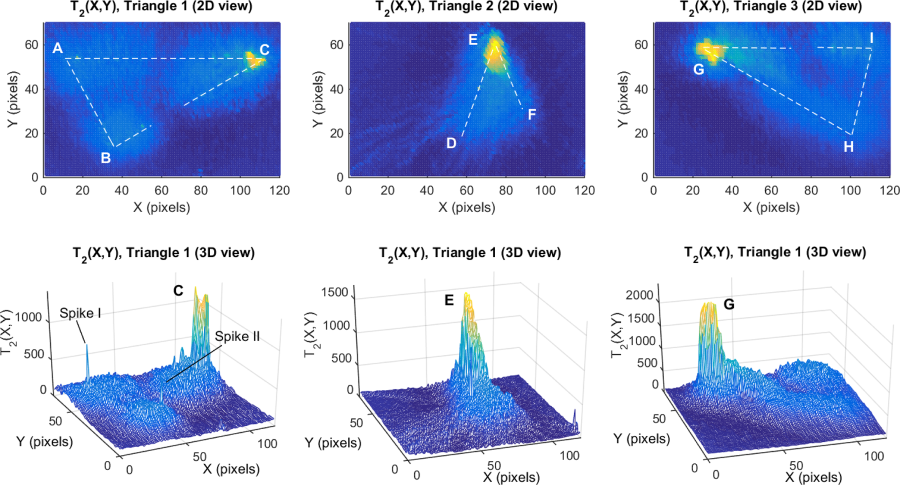

Real-time detection of clustered events in video-imaging data with applications to additive manufacturing

H. Yan, M. Grasso, K. Paynabar, and B. M. Colosimo

IISE Transactions, vol. 54, no. 5, pp. 464–480

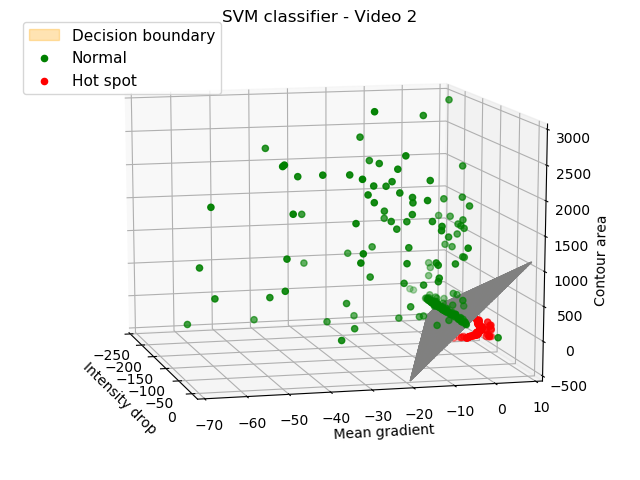

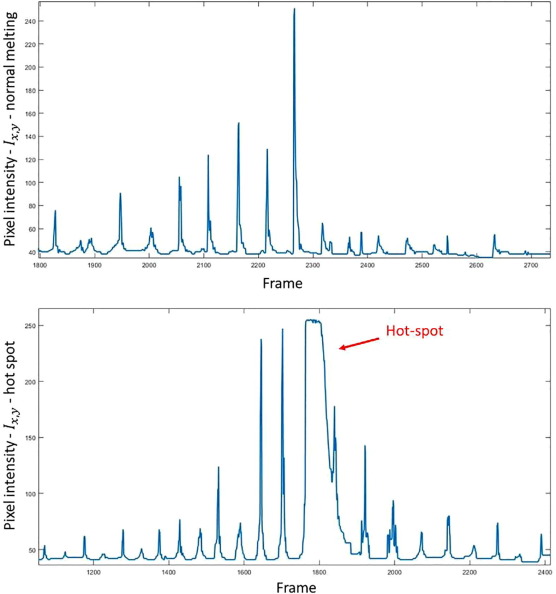

Towards real-time in-situ monitoring of hot-spot defects in L-PBF: a new classification-based method for fast video-imaging data analysis

Bugatti, M., Colosimo, B.M.

Journal of Intellingent Manufacturing, vol. 33, no. 1, pp. 293–309, 2022

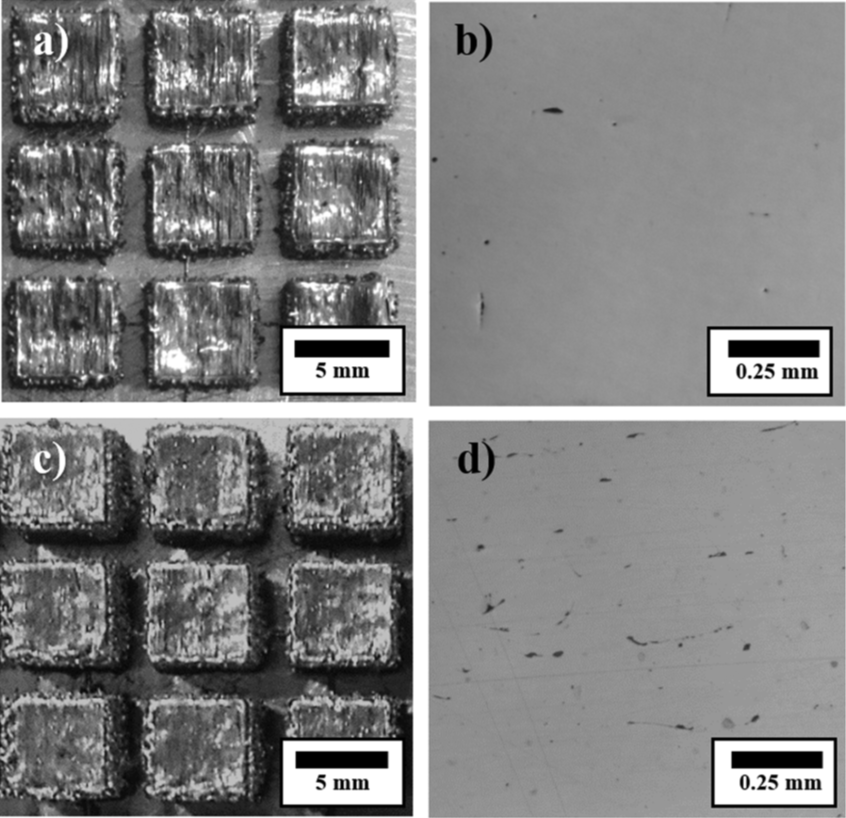

Enabling multi-material gradient structure in laser powder bed fusion

A. G. Demir, J. Kim, F. Caltanissetta, A. J. Hart, C. C. Tasan, B. Previtali and B. M. Colosimo

Journal of Materials Processing Technologies, vol. 301

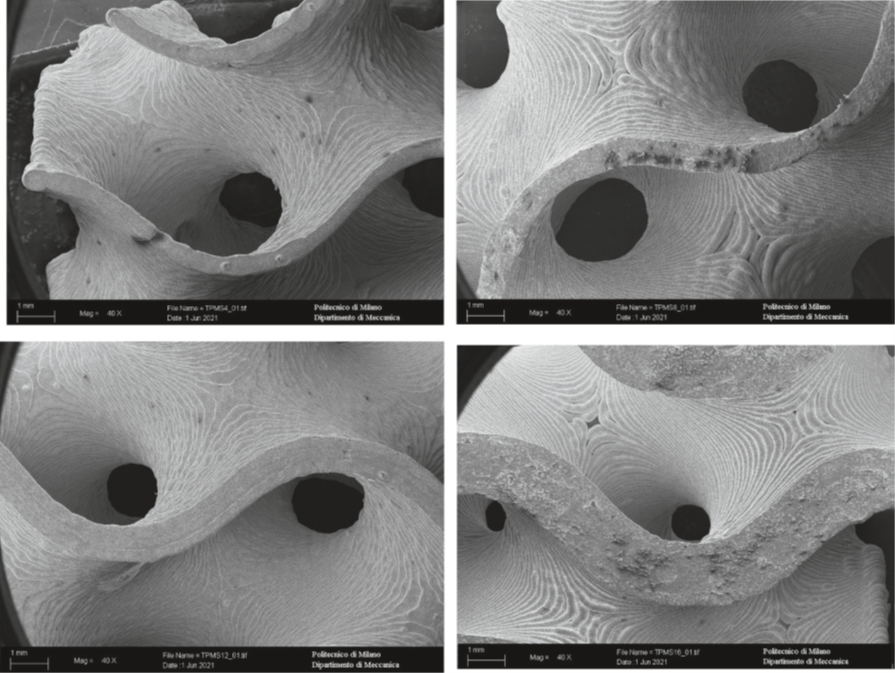

A new solution for assessing the printability of 17-4 PH gyroids produced via extrusion-based metal AM

P. Parenti, D. Puccio, B. M. Colosimo, and Q. Semeraro

Journal of Manufacturing Processes, vol. 74, no. January, pp. 557–572

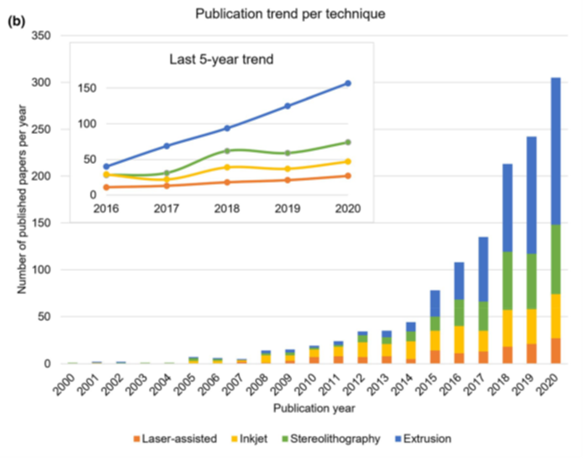

3D bioprinting: current status and trends—a guide to the literature and industrial practice

S. Santoni, S. G. Gugliandolo, M. Sponchioni, D. Moscatelli, and B. M. Colosimo

Bio-Design Manufacturing, vol. 5, no. 1, pp. 14–42

2021

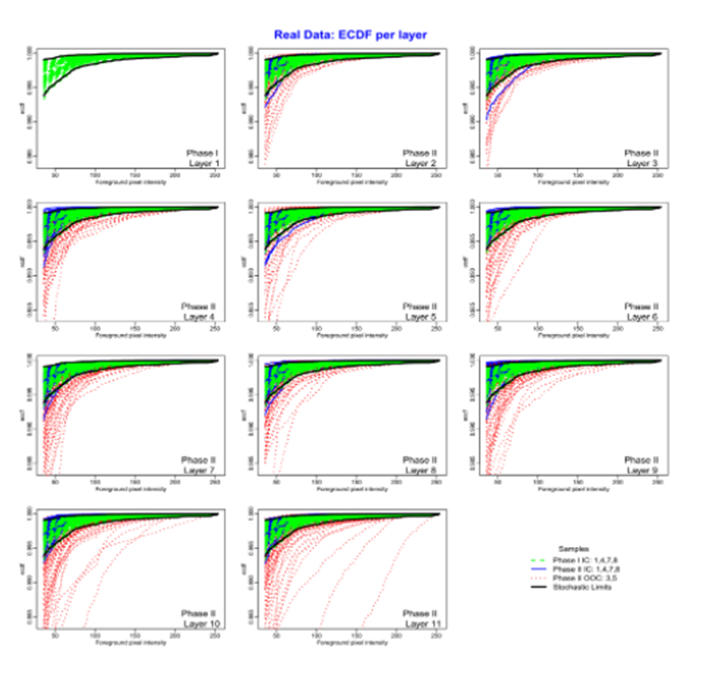

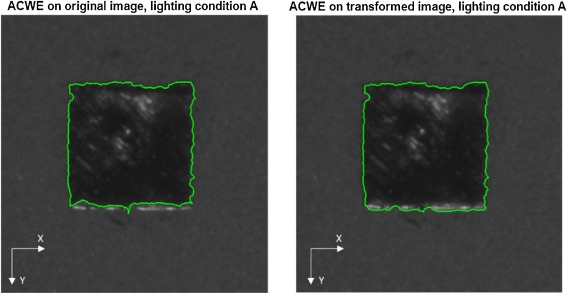

Image based Statistical Process Monitoring via Partial

First Order Stochastic Dominance

Tsiamyrtzis, P., Grasso, M., Colosimo, B.M.

Quality Engineering, vol. 34, no. 1, pp. 96–124

Available Dataset:

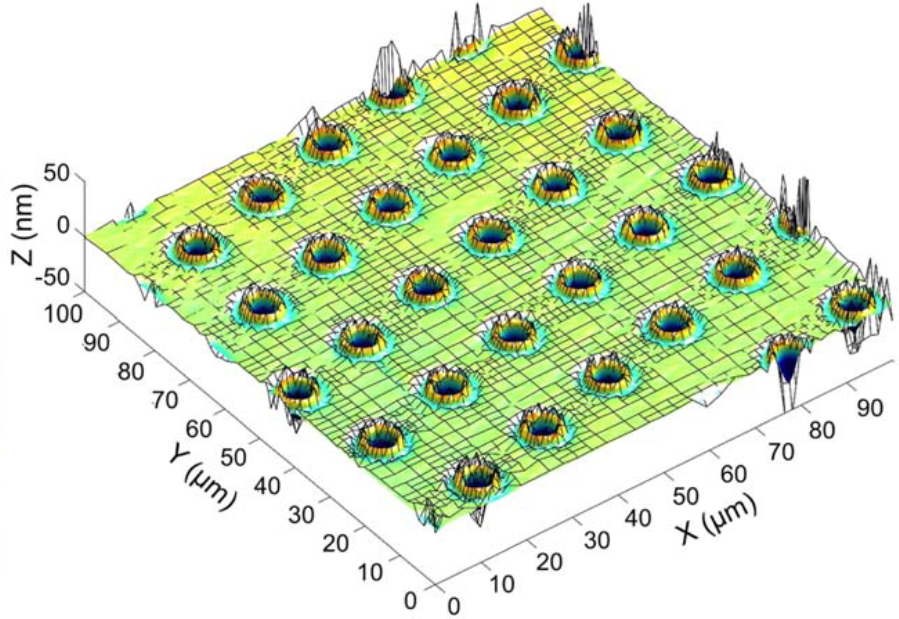

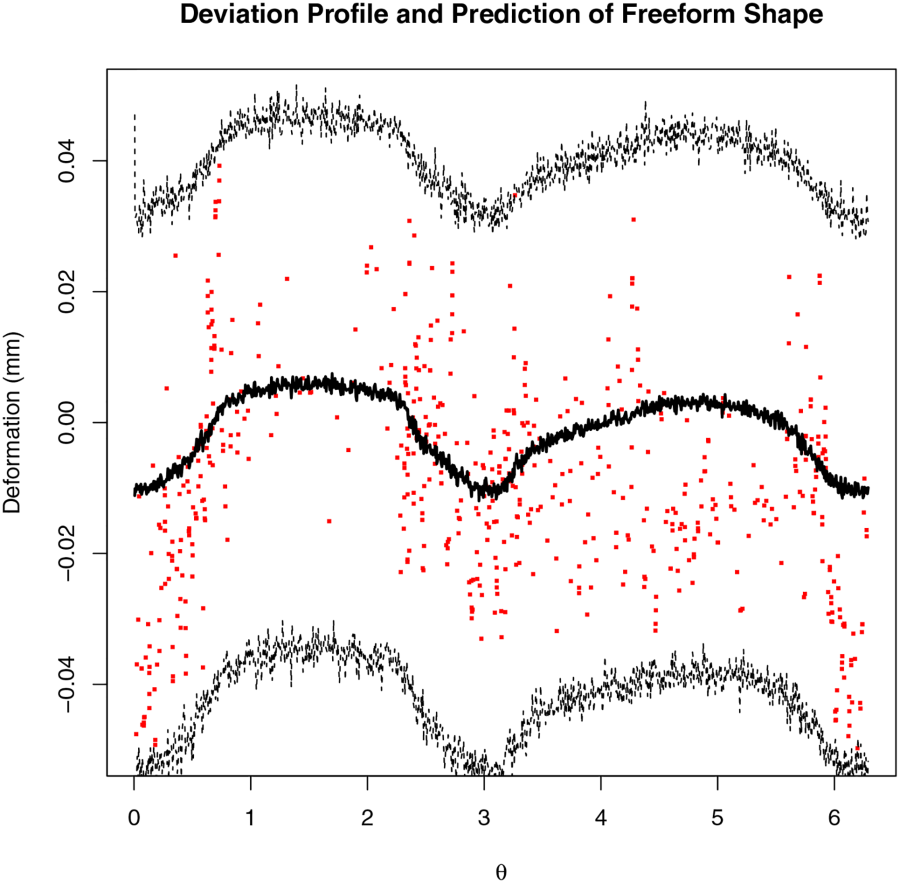

Characterisation of freeform, structured surfaces in T-spline spaces and its applications

J. Wang, R. Zou, B. M. Colosimo, W. Lu, L. Xu, and X. J. Jiang

Surface Topography: Metrology and Properties, vol. 9, no. 2

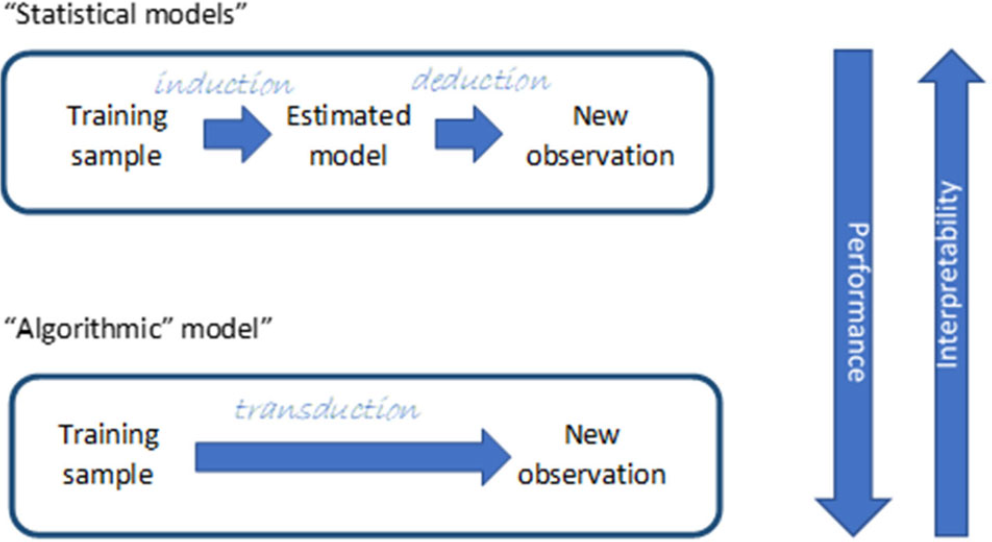

Artificial intelligence and statistics for quality technology: an introduction to the special issue

B. M. Colosimo, E. del Castillo, L. A. Jones-Farmer, and K. Paynabar

Journal of Quality Technology, vol. 53, no. 5, pp. 443–453

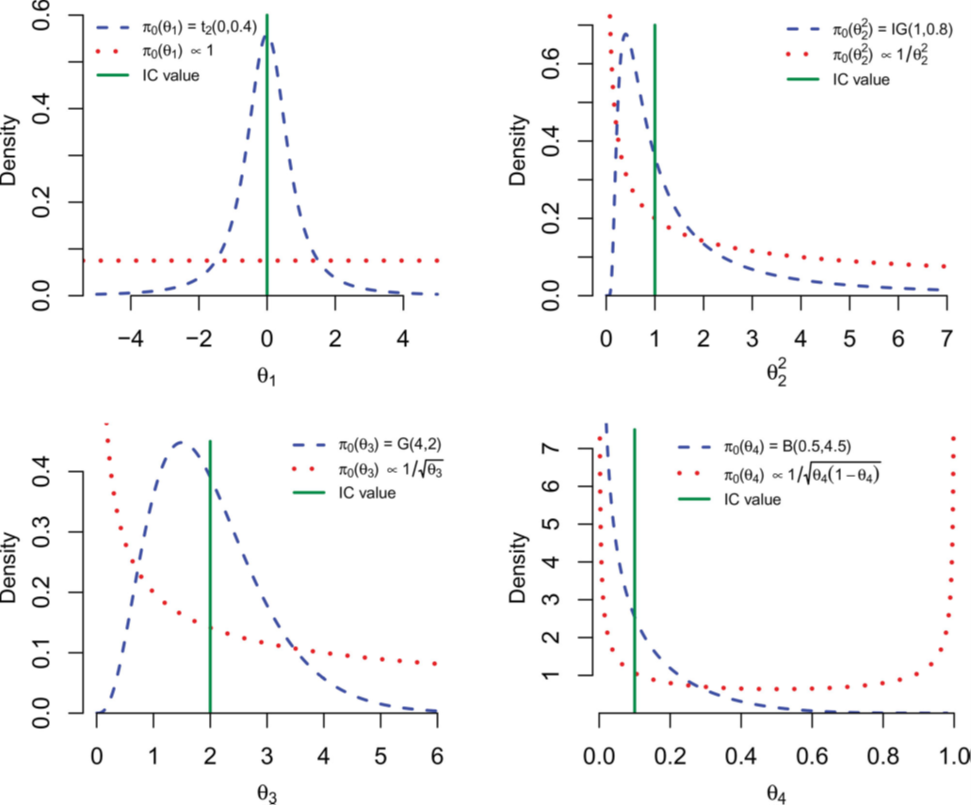

Predictive Control Charts (PCC): A Bayesian approach in online monitoring of short runs

K. Bourazas, D. Kiagias, and P. Tsiamyrtzis

Journal of Quality Technology, pp. 1–35

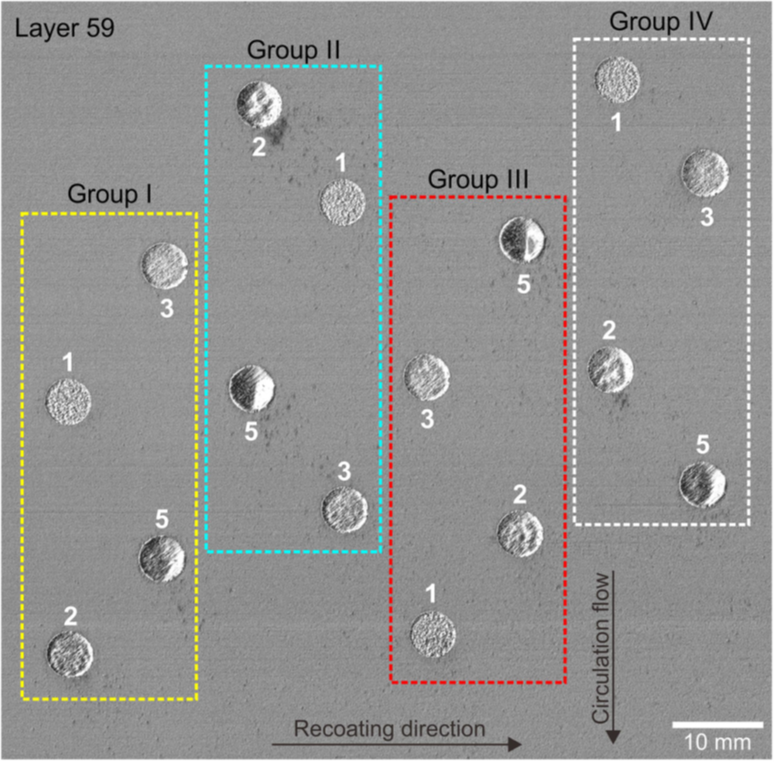

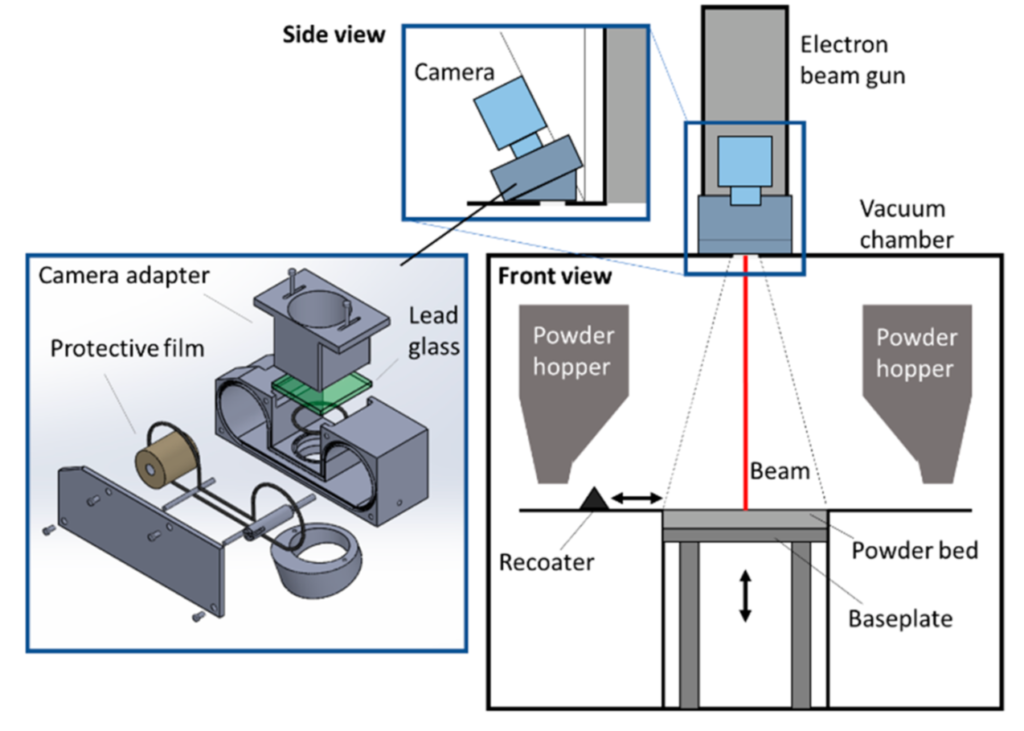

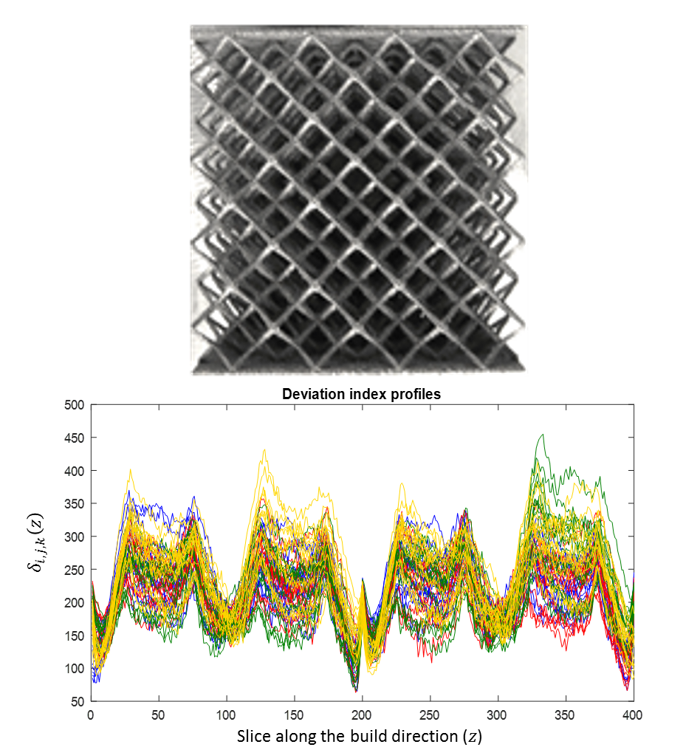

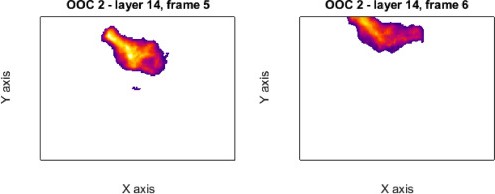

In situ monitoring of powder bed fusion homogeneity in electron beam melting

M. Grasso

Materials (Basel)., vol. 14, no. 22

Towards real-time in-situ monitoring of hot-spot defects in L-PBF: a new classification-based method for fast video-imaging data analysis

Bugatti, M., Colosimo, B.M.

Journal of Intelligent Manufacturing, in press

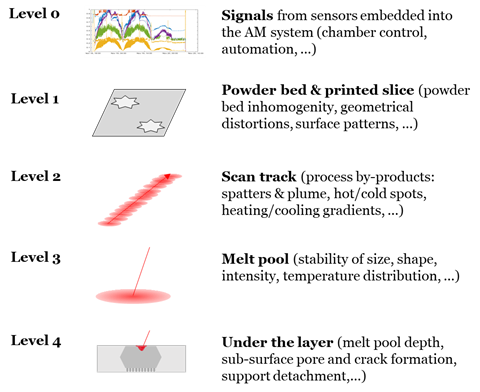

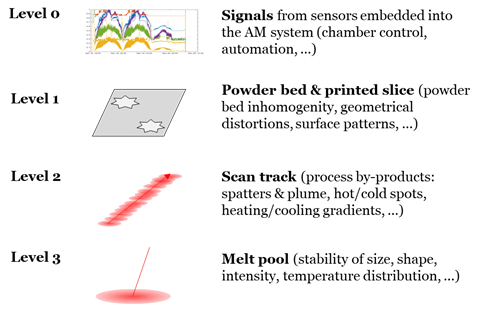

In-situ measurement and monitoring methods for metal powder bed fusion – an updated review

M. Grasso, A. Remani, A. Dickins, B. M. Colosimo, and R. K. Leach

Meas. Sci. Technol., vol. 32, no. 11

Direct laser additive manufacturing of high performance oxide ceramics: a state-of-the-art review

Pfeiffer, S., Florio, K., Puccio, D., Grasso, M., Colosimo, B. M., Aneziris, C. G., Wegener, K., Graule, T.

Journal of the European Ceramic Society, in press

Process Characterization and Analysis of Ceramic Powder Bed Fusion

Florio, K., Puccio, D., Pfeiffer, S., Verga, F., Grasso, M., Colosimo, B.M., Graule, T., Wegener, K.

under review in Journal of the European Ceramic Society

Statistical modeling and monitoring of geometrical deviations in complex shapes with application to Additive Manufacturing

Scimone, R., Taormina, T., Colosimo, B.M., Grasso, M., Menafoglio, A., Secchi, P.

under review in Technometrics

Compression behaviour of EBM printed auxetic chiral structures

Gunaydin, K., Turkmen, H. S., Airoldi, A., Grasso, M., Sala, G., Grande, A. M.

under review in Meccanica

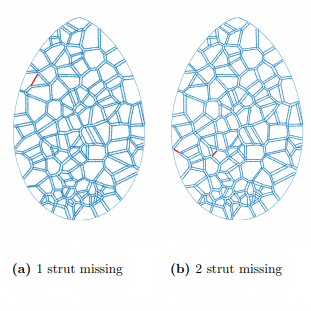

Novel solutions for lattice structure modelling and monitoring

Colosimo B.M., Garghetti, F., Grasso, M.

Journal of Quality Technology, in press

Penalized Spatio-temporal Regression for Anomaly Detection in Video-Imaging Data with Application to Hot-spot Detection in Laser Powder Bed Fusion

Yan, H., Grasso, M., Paynabar, K., Colosimo, B.M.

IISE Transactions

2020

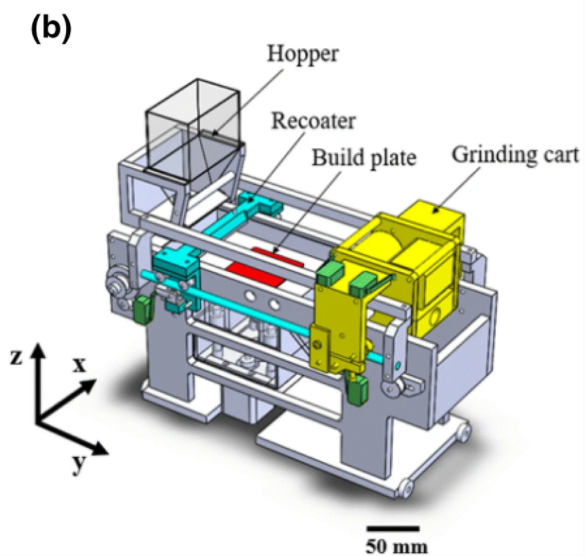

Penelope: a novel prototype for in-situ defect removal in LPBF

Colosimo, B.M., Grossi, E., Caltanissetta, F., Grasso, M.

JOM

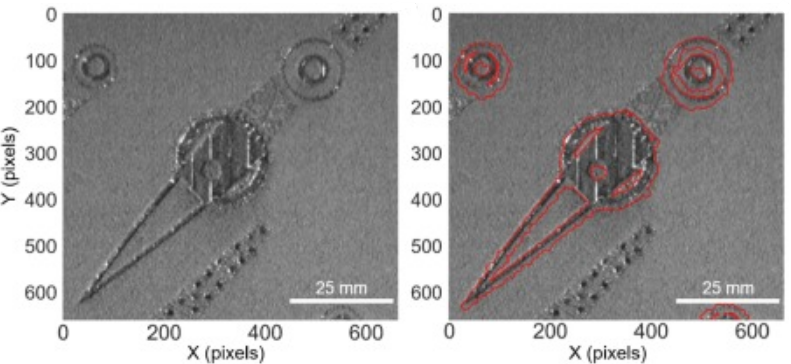

Automated layerwise detection of geometrical distortions in laser powder bed fusion

Pagani, L., Grasso, M., Scott, P. J., & Colosimo, B. M.

Additive Manufacturing, 36, 101435

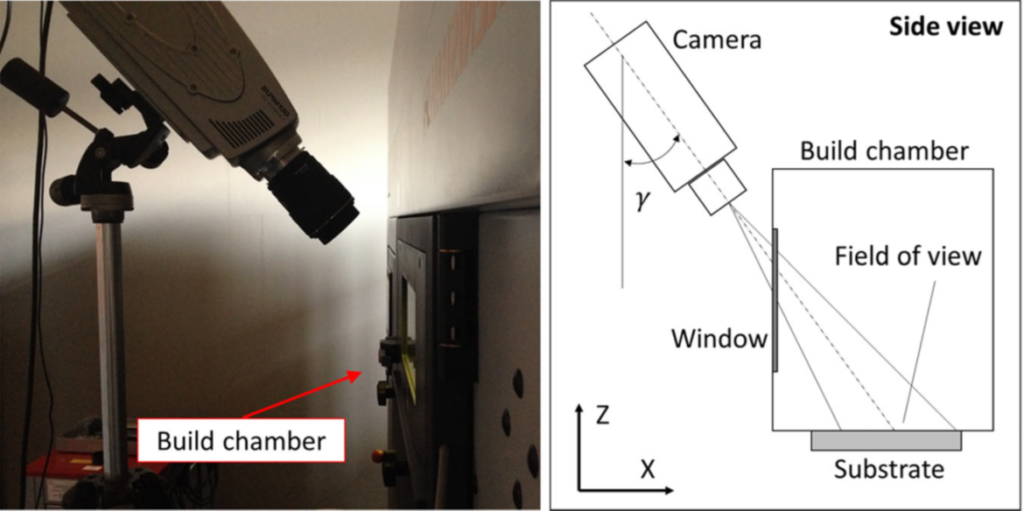

Powder bed irregularity and hot-spot detection in Electron Beam Melting by means of in-situ video imaging

Grasso, M., Valsecchi, G., Colosimo, B.M.

Manufacturing Letters, 24, 47-51

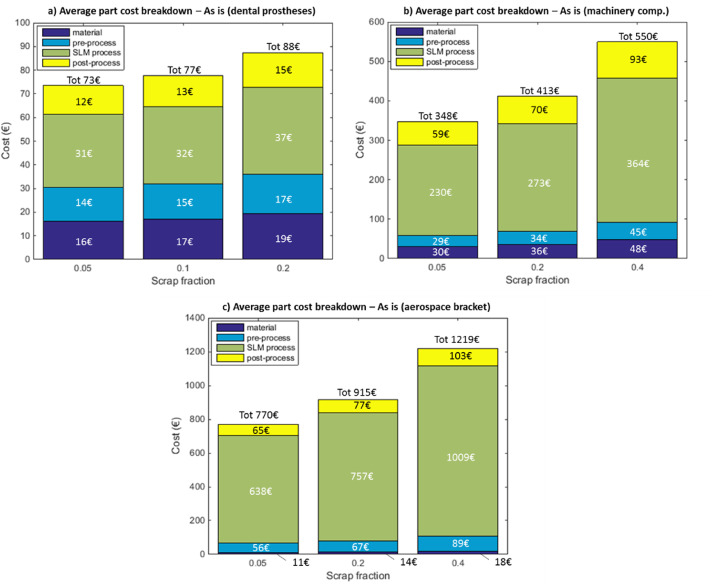

A cost model for the economic evaluation of in-situ monitoring tools in metal additive manufacturing

Colosimo, B.M., Cavalli, S., Grasso, M.

International Journal of Production Economics, 223, 107532

2019

A Statistical Learning Method for Image-based Monitoring of the Plume Signature in Laser Powder Bed Fusion

Grasso, M., Colosimo, B.M.

Robotics and Computer-Integrated Manufacturing, 57, 103-115

Prescriptive Data-Analytical Modeling of Laser Powder Bed Fusion Processes

He, L., Grasso, M., Colosimo, B.M., Huang, Q.

Journal of Manufacturing Science and Technology, 141(1): 011008

2018

Characterization of In-Situ Measurements based on Layerwise Imaging in Laser Powder Bed Fusion

Caltanissetta F., Grasso M., Petrò S., Colosimo, B. M.

Additive Manufacturing, 24, 183-199

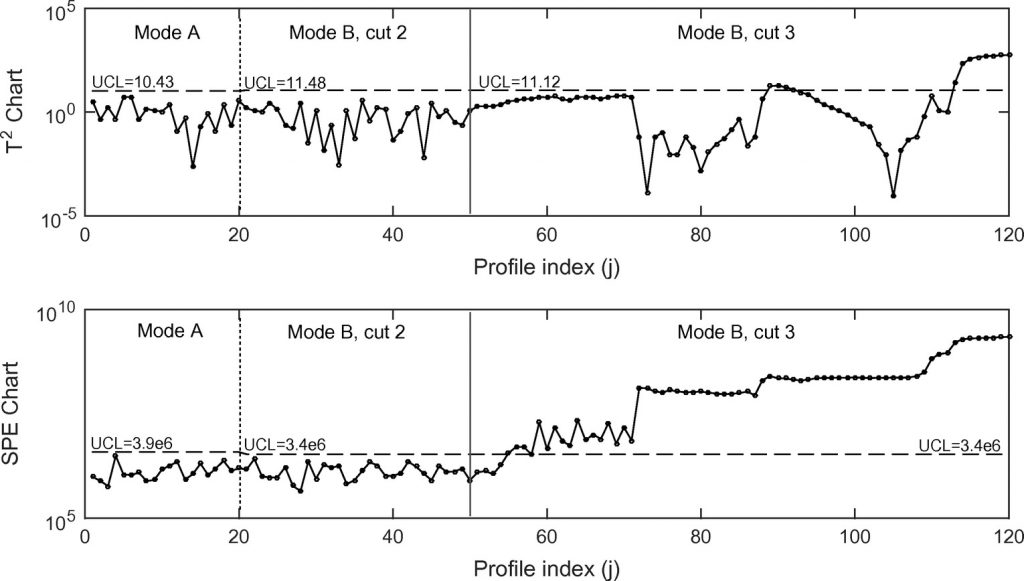

Spatially weighted PCA for monitoring video image data with application to additive manufacturing

Colosimo, B.M., Grasso, M.

Journal of Quality Technology, 50(4), 391-417

Available dataset:

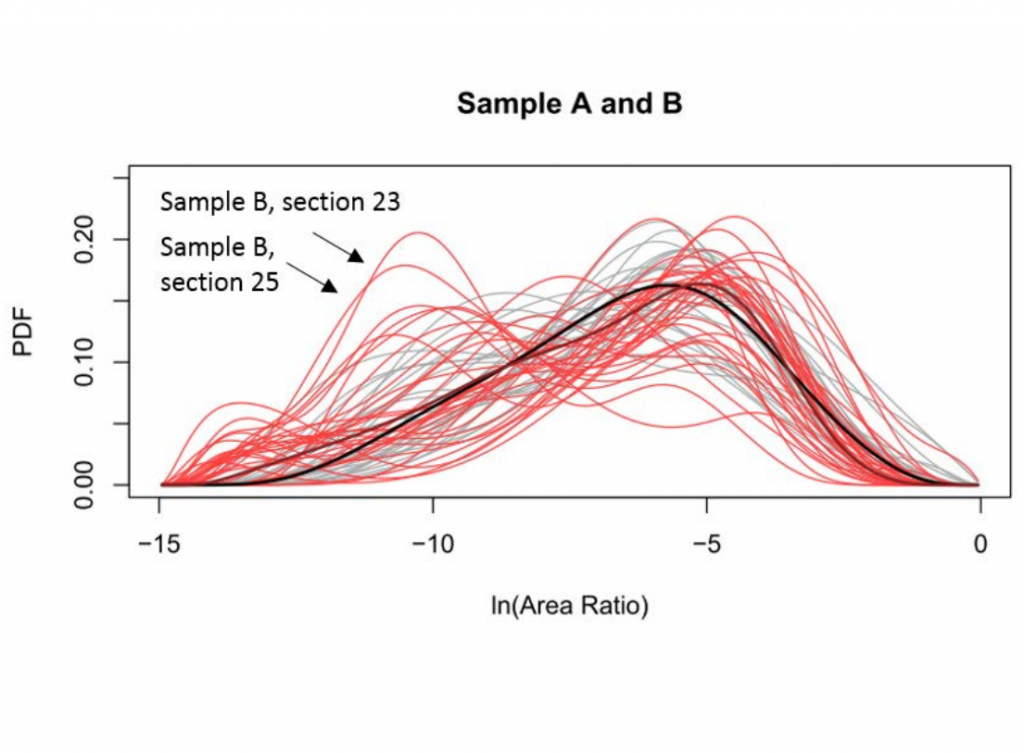

Profile Monitoring of Probability Density Functions for Image Data via Simplicial Functional Principal Component Analysis

Menafoglio A., Grasso M., Secchi P., Colosimo B.M.

Technometrics, 60(4), 497-510

In-situ Monitoring of Selective Laser Melting of Zinc Powder via Infrared Imaging of the Process Plume

Grasso, M., Demir, A.G., Previtali, B., Colosimo, B.M.

Robotics and Computer-Integrated Manufacturing, 49, 229-239

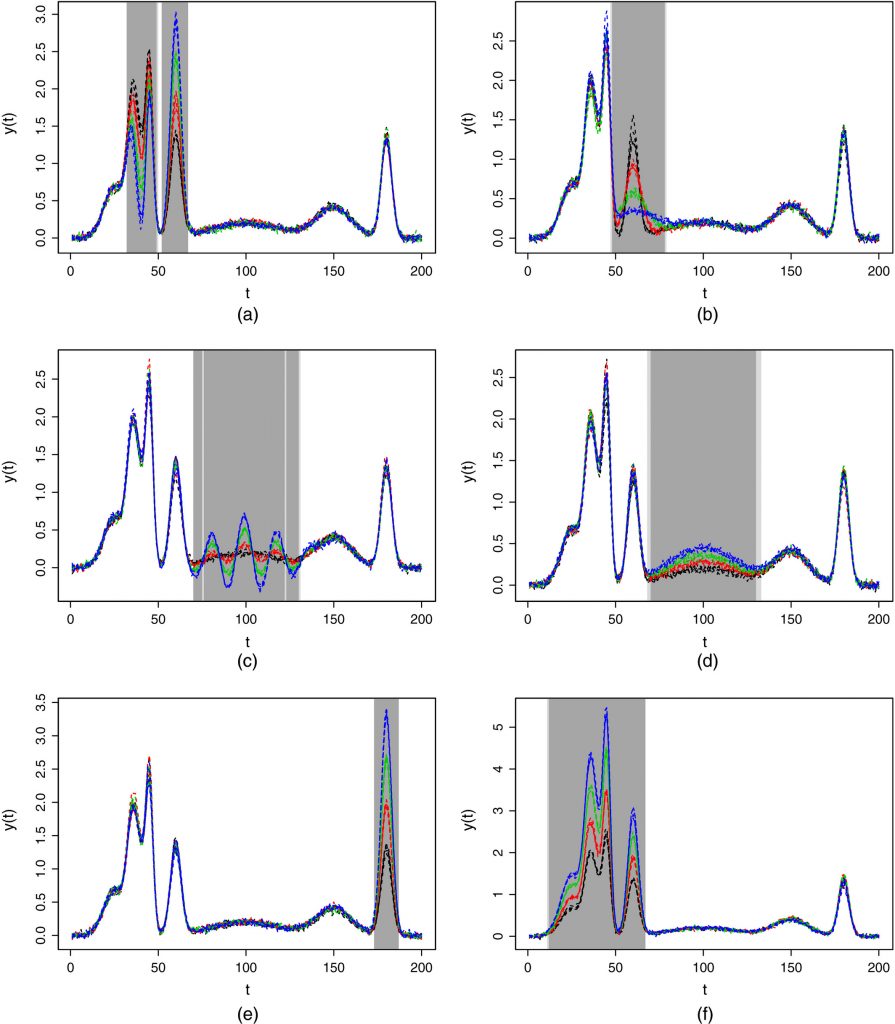

Domain-Selective Functional ANOVA for Supervised Statistical Profile Monitoring of Signal Data

Pini A., Vantini S., Colosimo B.M., Grasso M.

Journal of the Royal Statistical Society: Series C (Applied Statistics), 67(1), 55-81

2017

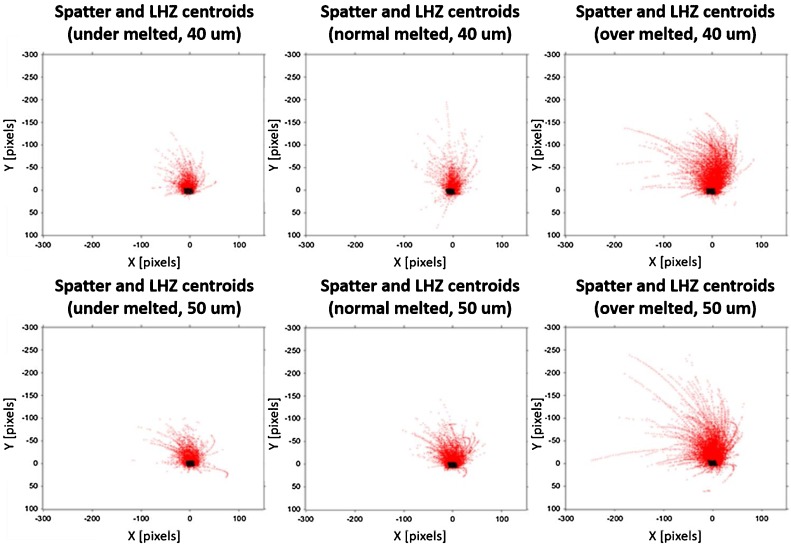

On the use of spatter signature for in-situ monitoring of Laser Powder Bed Fusion

Repossini G., Laguzza V., Grasso M., Colosimo B.M.

Additive Manufacturing, 16, 35-48

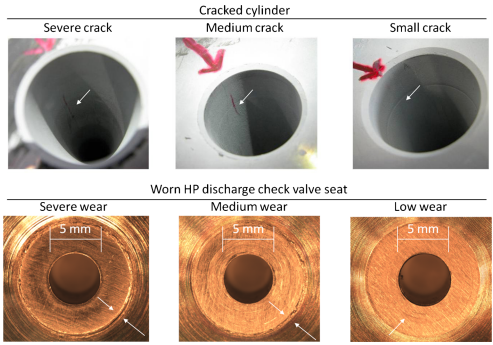

Process Defects and In-situ Monitoring Methods in Metal Powder Bed Fusion: a Review

Grasso M., Colosimo B.M.

Measurement Science and Technology, 28(4), 1-25

In-process Monitoring of Selective Laser Melting: Spatial Detection of Defects via Image Data Analysis

Grasso M., Laguzza V., Semeraro Q., Colosimo B.M.

Journal of Manufacturing Science and Engineering, 139(5), 051001-1 – 051001-16

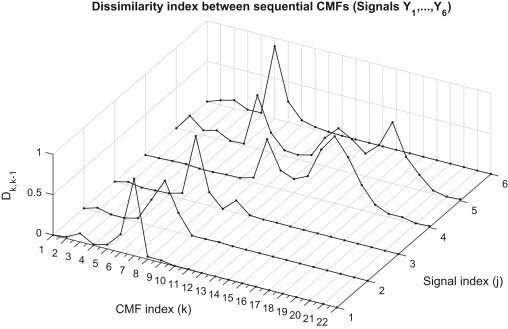

A phase I multi-modelling approach for profile monitoring of signal data

Grasso, M., Colosimo, B. M., Tsung, F.

International Journal of Production Research, 55(15), 4354-4377

2016

A Data-Driven Method to Enhance Vibration Signal Decomposition for Rolling Bearing Fault Analysis

Grasso M., Chatterton S., Pennacchi P., Colosimo B.M.

Mechanical Systems and Signal Processing, 81, 126-147

An Automated Approach to Enhance Multi-Scale Signal Monitoring of Manufacturing Processes

Grasso M., Colosimo B.M.

Journal of Manufacturing Science and Engineering, 138(5), 051003-1 – 051003-16

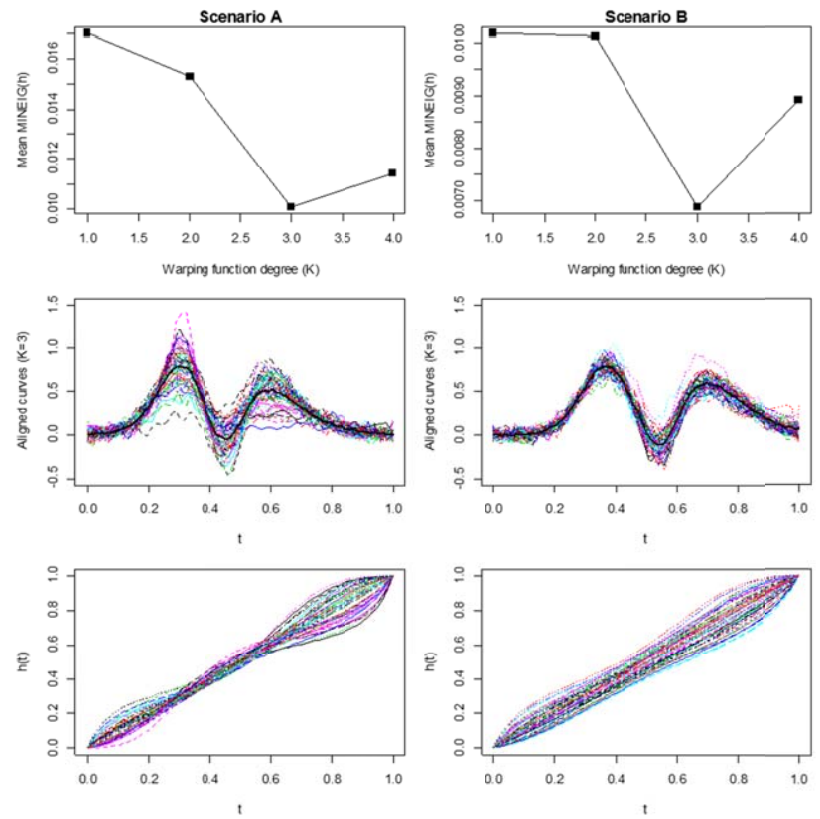

Using Curve Registration Information to Enhance Profile Monitoring of Signal Data

Grasso M., Menafoglio A., Colosimo B. M., Secchi P.

Journal of Quality Technology, 48(2), 99-127

2015

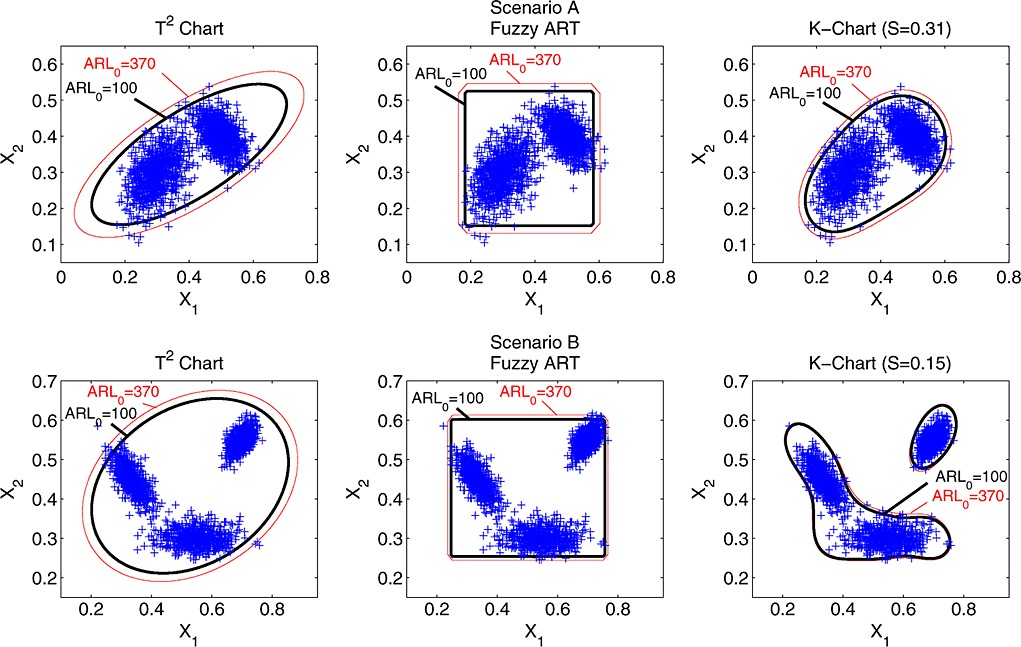

A Comparison Study of Distribution-Free Multivariate SPC Methods for Multimode Data

Grasso M., Colosimo B.M., Semeraro Q., Pacella M.

Quality & Reliability Engineering International, 31 (1), 75 – 96

2014

Empirical mode decomposition of pressure signal for health condition monitoring in waterjet cutting

Grasso M., Pennacchi P., Colosimo B. M.

The International Journal of Advanced Manufacturing Technology, 72:1-4, 347-364

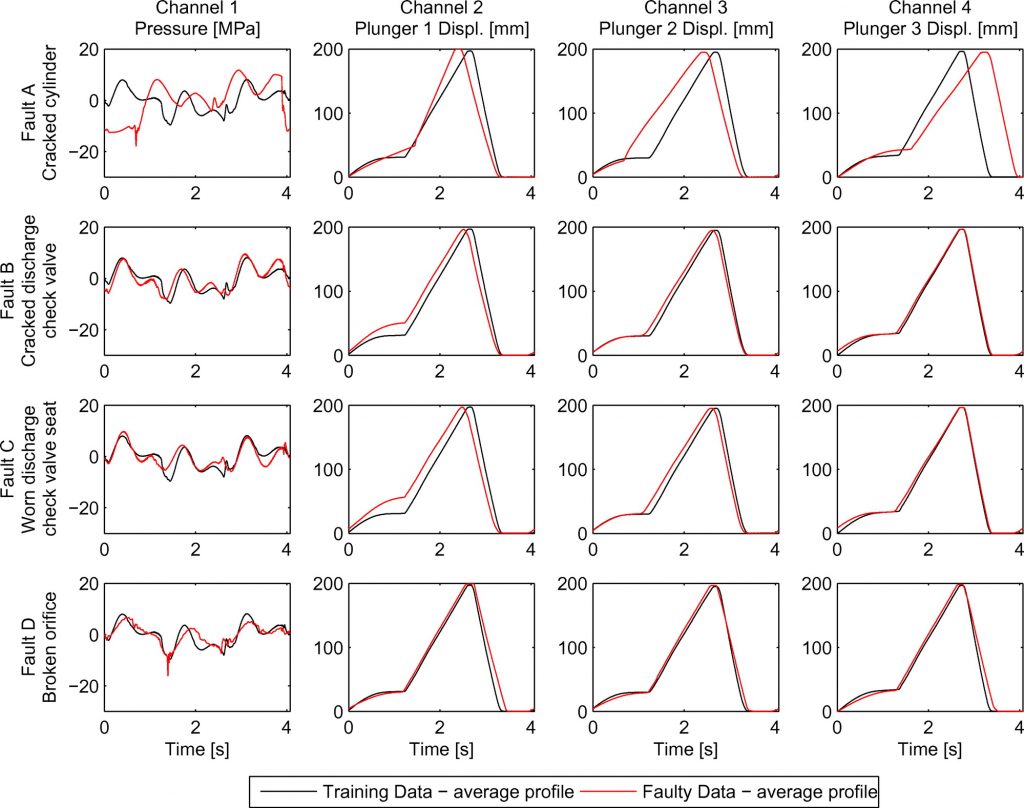

Profile Monitoring via Sensor Fusion: the use of PCA Methods for Multi-Channel Data

Grasso M., Colosimo B.M., Pacella M.

International Journal of Abrasive Technology, 6(2), 158-181

2013

A New Approach for On-Line Health Assessment of Abrasive Waterjet Cutting Systems

Grasso M., Goletti M., Annoni M., Colosimo B.M.

International Journal of Abrasive Technology, 6(2), 158-181